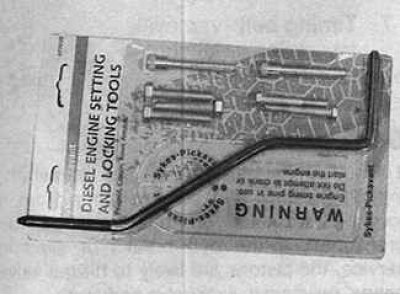

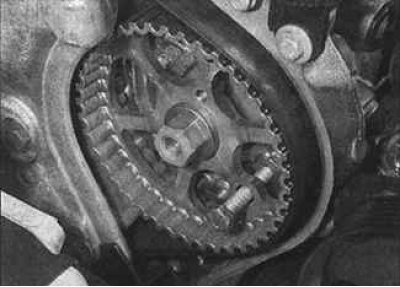

A tool for locking the valve timing mechanism

All models have mounting holes in the camshaft pulley, fuel pump pulley and flywheel. Locating holes are used to position the crankshaft, camshaft, and fuel pump in a position that prevents the pistons and valves from hitting when installing the cylinder head or timing belt.

When the locating holes on the pulleys align with the holes in the cylinder head and cylinder block, the locating pins must be inserted into them (or matching bolts) and fix the camshaft, fuel pump and crankshaft from turning. In this case, the #4 cylinder piston is at top dead center on the compression stroke.

1. Remove the top casing of a gear belt.

2. Turn the crankshaft until the holes in the camshaft pulley and the fuel pump pulley are aligned (one hole in the camshaft pulley, one or two holes in the fuel pump pulley) with holes in the engine. The crankshaft can be rotated by the pulley bolt. To access the pulley mounting bolt, remove the wheel arch from under the wing. If necessary, move the coolant hoses away from the suspension. Turn the crankshaft only clockwise when looking at the engine from the right side of the vehicle.

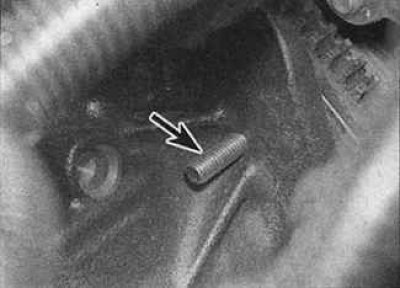

3. Install rod (indicated by an arrow) with a diameter of 8 mm through the hole in the left projection of the cylinder block near the starter. If necessary, carefully rotate the crankshaft until the rod is seated in the hole in the flywheel.

4. On 2.1 liter engines, access is limited and the starter may have to be removed to install the rod.

|  |

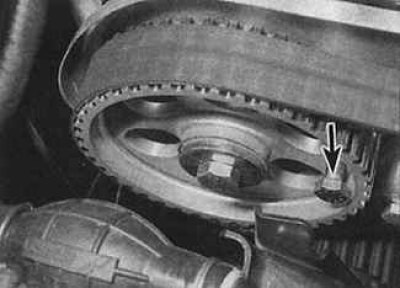

5. Insert 8mm bolt (indicated by an arrow) through a hole in the camshaft pulley (on the left - on a 1.9 liter engine, on the right - on a 2.1 liter engine).

|  |

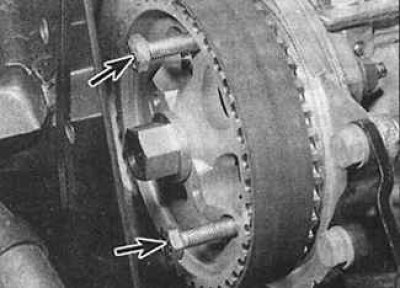

6. Insert two (indicated by arrows) bolt (on the left - on a 1.9 liter engine) or one (on the right - on a 2.1 liter engine) bolt through the high pressure fuel pump pulley and screw them into the engine.

7. The crankshaft, camshaft and fuel pump are fixed in a position that prevents them from rotating.