Removing

Models with manual transmission

1. Remove the gearbox and clutch.

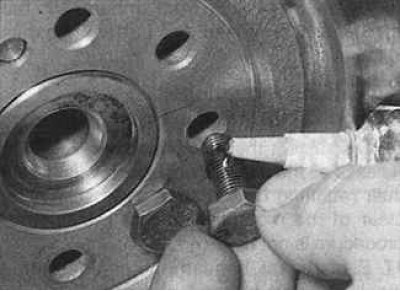

2. Secure the flywheel against turning by placing a lock on the flywheel ring gear.

3. Unscrew bolts and remove a flywheel. If there is a guide pin, remove it and store it with the flywheel. The flywheel bolts are always replaced with new ones.

Models with automatic transmission

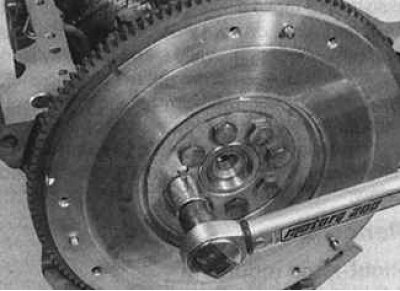

4. Remove the gearbox. Mark the location of the torque converter in relation to the flywheel and loosen the flywheel mounting bolts.

5. Remove the flywheel mounting bolts along with the torque converter and two gaskets. Please note that the gaskets have different thicknesses, the thicker one is on the outside of the torque converter.

6. Remove the flywheel from the crankshaft. If there is a guide pin, remove it and store it with the flywheel.

Examination

1. On models with a manual transmission, check the flywheel for wear on the clutch side and the condition of the ring gear teeth. If the ring gear is worn out, the flywheel must be replaced, because. ring gear is not supplied separately.

2. On models with automatic transmission, check the condition of the torque converter drive and ring gear.

Installation

Models with manual transmission

1. Clean the mating surfaces of the flywheel and crankshaft. Remove residual sealant from the threaded holes of the crankshaft using a tap.

2. If new bolts are used that are not coated with sealant, then apply sealant to the threaded part of the bolts before installation.

3. Install the pilot pin in the socket and install the flywheel, aligning the holes in the flywheel with the pilot pin.

4. Secure the flywheel against rotation and screw in the mounting bolts.

5. Install the clutch and remove the flywheel lock. Install the gearbox.

Models with automatic transmission

6. Clean the mating surfaces of the flywheel and crankshaft. Remove residual sealant from the threaded holes of the crankshaft using a tap. If new bolts are used that are not coated with sealant, apply sealant to the threads of the bolts before installation.

7. Install the pilot pin in the socket and install the flywheel, aligning the holes in the flywheel with the pilot pin.

8. Install the torque converter actuator with a thinner gasket on the rear of the actuator and a thicker gasket on the outside. Align it with the marks made during removal.

9. Install new mounting bolts and tighten them to the correct torque.

10. Remove the flywheel lock and install the gearbox.