Attention! The engine can only be removed from a vehicle with a gearbox.

Removing

1. Park the vehicle on a level surface, block the rear wheels, raise the front of the vehicle and support it on stands. Remove both front wheels.

2. Open the hood and secure it in an upright position.

3. Disconnect the negative battery terminal.

4. Drain the coolant from the cooling system.

5. Remove both drive shafts.

6. Remove the air filter housing and intake pipe system. Unscrew the bolts and remove the air filter support bracket.

7. On models with a 2.1 liter diesel engine, remove the ECU fuel system and control unit.

8. Disconnect the accelerator cable from the throttle body or high pressure fuel pump.

9. Remove the throttle body.

10. Remove the wires, connectors and other components from the left front end of the cylinder head.

11. Drain the engine oil and remove the oil filter. Clean and install the drain plug, tightening to the correct torque.

12. Drain the oil from the gearbox, install the drain and filler plugs and tighten them to the required torque.

13. Disconnect the wires from the gearbox.

14. Remove the speedometer cable or transducer wiring from the transmission.

15. Using a screwdriver blade as a lever, disconnect the gear selector mechanism from the corresponding ball joints on the gearbox.

16. Remove the crankshaft position sensor.

17. Remove the clutch cable from the clutch release lever and disconnect it from the gearbox housing. On 2.1 liter diesel engines, remove the clutch slave cylinder.

18. Remove the power steering pump without unscrewing the hydraulic hoses from it. Using a soft wire, hang the pump away from the engine.

19. Remove the generator.

20. On models with air conditioning, unscrew the compressor mounting bolt and, using soft wire, secure it away from the engine.

21. On 2.1 liter engines, unscrew the additional suspension bolt from the front of the cylinder block.

22. Remove the radiator.

23. On vehicles with petrol engines, do the following:

- depressurize the fuel system and disconnect the supply and return fuel hoses;

- disconnect the electrical connectors of the fuel system;

- disconnect the ventilation valve from the intake manifold;

- remove the exhaust pipe.

24. On diesel models, disconnect the fuel supply and return hoses.

25. Release the clamps and remove the heater hoses from the adapter on the bulkhead of the engine compartment.

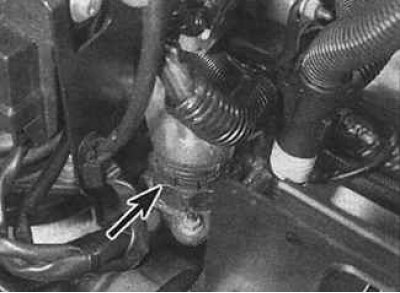

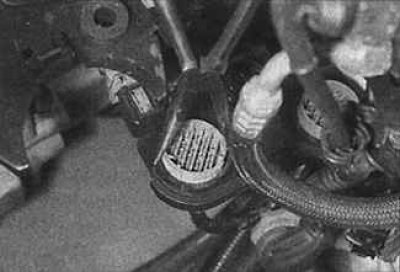

|  |

26. Trace the wiring harness from the engine to the connector in the engine compartment. Disconnect the connectors, remove the retaining rings and remove the connectors, having previously marked their location (arrow). Check that all connectors are disconnected and the electrical wiring is removed from the brackets and supports and will not interfere with the removal of the engine.

27. Hook the hoist onto the hangers on the cylinder head and lift until the weight of the engine is supported by the hoist.

28. Remove the right and left suspension brackets of the power unit.

29. From the bottom of the car, unscrew the nuts and bolts securing the travel stops to the lower frame and engine and remove them.

30. Check that all elements that prevent the removal of the engine are removed or disabled.

31. Lift the engine up from the engine compartment. On models with ABS, great care must be taken not to damage the ABS during engine removal.

32. After removing the engine from the engine compartment, lower it to the ground in front of the vehicle.

Separation of the gearbox from the engine

1. Install the power unit on the appropriate bars.

2. Unscrew the mounting bolts and remove the lower flywheel protective plate from the gearbox housing.

3. On models with a cable release mechanism, unscrew the mounting bolt and remove the clutch release lever from the top of the shaft. Mark the location of the clutch release shaft relative to the gearbox housing.

4. Unscrew the mounting bolts and remove the starter.

5. Check that the engine and gearbox are securely fixed. Then unscrew the remaining bolts securing the gearbox housing to the engine.

6. Being careful, separate the gearbox from the engine so that the weight of the gearbox does not press on the input shaft.

7. Remove guide pins.

8. On models with a cable-actuated clutch, make a second mark on the relative position of the fork after removal.

Installation

1. Connect the gearbox to the engine.

2. Check that the guide pins are installed in the engine or gearbox.

3. On cable-operated clutch release models, before reinstalling, install the release bearing so that the mark on the shaft is aligned with the second mark on the gearbox housing.

4. Install the gearbox to the engine on the guide pins.

5. On models with a cable-actuated clutch, check that the clutch release fork and release bearing are correctly installed, i.e. the mark on the fork is aligned with the original mark made on the gearbox housing.

6. Establish and tighten bolts of fastening of a transmission to the engine by the demanded moment.

7. Install starter and bolt on.

8. On models with a cable release mechanism, install the clutch release lever on the shaft and secure it with bolts.

9. Install the bottom flywheel skid plate to the transaxle case and secure with bolts.

10. Hook the engine with a lifting device and install it in the engine compartment.

11. When installing the power package, if necessary, tilt and rotate it so that it is installed in place without causing harm.

12. Install the right power unit suspension, tightening the nuts and bolts at this stage only by hand.

13. Install the left powertrain mount hand-tight only.

14. From below the car establish the limiter of a course.

15. Swing the engine to the sides so that all suspension elements are in place, then tighten them to the required torque and unhook the lifting mechanism.

16. Further installation is carried out in the reverse order of removal.