As for the diesel engine, it does not need the ignition system required by gasoline engines. In diesel engines there is a strong compression of the incoming air, accompanied by a significant increase in temperature. When fuel is injected into compressed and heated air, it self-ignites.

Depending on the configuration, the ignition system of the cars in question may be static - without an ignition distributor, the leads of the ignition coil are directly connected to the high voltage wires of the spark plugs. The distributorless ignition system means that the secondary winding of the ignition coil generates the high voltage current required for the spark discharge. This voltage through the distributor is supplied from the coils to the spark plugs through high voltage wires.

All engines with a fuel injection system are equipped with an ignition system controlled by the same electronic unit as the fuel injection system.

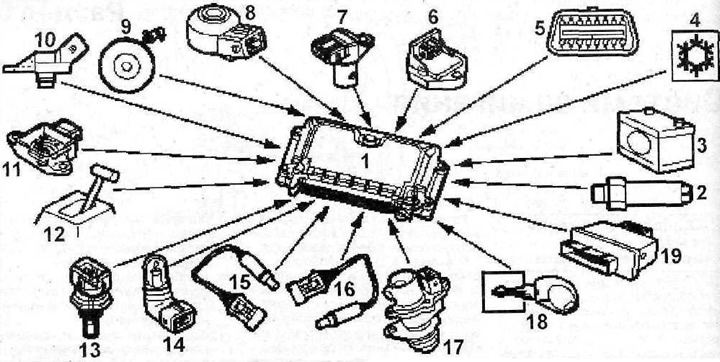

The electronic control unit has a multi-pin plug connector, which allows you to provide power to the parts of the injection and ignition systems, while also receiving information from the elements of these systems (see illustrations 1.0 and 1.0a).

1.0 Input signals to the electronic control unit for injection and ignition systems

1 - control unit for injection and ignition systems

2 - hydraulic fluid pressure sensor

3 - battery

4 - refrigerant pressure sensor (if provided)

5 - diagnostic connector

6 - accelerator pedal position sensor

7 - crankshaft position sensor

8 - knock sensor

9 - speedometer sensor

10 - air pressure sensor in the intake manifold

11 - throttle position potentiometer

12 - automatic transmission control unit (depending on configuration)

13 - coolant temperature sensor

14 - intake air temperature sensor

15 - lambda probe (oxygen sensor)

16 - lambda probe (oxygen sensor)

17 - input shaft rotation speed sensor

18 - immobilizer

19 - engine control unit relay

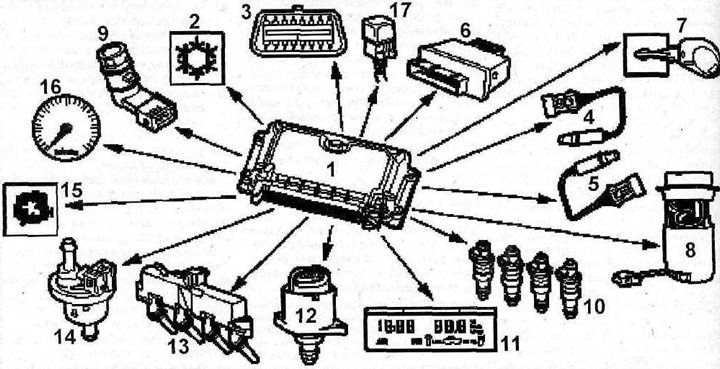

1.0a Actuators of injection and ignition systems

1 - control unit for injection and ignition systems

2 - refrigerant pressure sensor

3 - diagnostic socket

4 - lambda probe (oxygen sensor)

5 - lambda probe (oxygen sensor)

6 - engine control unit relay

7 - immobilizer

8 - fuel pump

9 - throttle valve heater

10 - fuel injectors

11 - on-board computer

12 - stepper motor idle speed controller

13 - block of ignition coils

14 - adsorber purge solenoid valve

15 - engine status signal light

16 - tachometer

17 - turbocharger relay (if provided)

The ignition coils are made in the form of a contact block mounted on the cylinder head.

The memory of the control unit for injection and ignition systems contains parametric data determined during bench and road tests of the engine. The control unit commands the ignition coils by applying appropriate pulses from the crankshaft position sender, which reads the number of revolutions of the crankshaft. In addition, the control unit receives information from the coolant temperature and intake air temperature sensors, as well as the throttle angle potentiometer.

The throttle valve potentiometer informs the electronic control unit about the position of the throttle valve, which can close the intake port, open it partially or completely. Based on the information received, the electronic control unit determines the mode of acceleration and increase in speed, braking or forced idling.

The electronic control unit calculates the ignition timing, sets the duration of the ignition coil charging in accordance with the engine speed, determines the battery voltage and the voltage on both coil windings.

Attention! The probability of damage to expensive system components when performing repair and adjustment work on your own is very high, so we recommend entrusting all work related to the ignition system to a specialized workshop.

To avoid high voltage shock during work, the following rules must be observed:

- A) persons with a pacemaker are not allowed to work with electronic ignition systems;

- b) do not touch or disconnect the wires of the ignition system, and do not crank the engine with the starter while the engine is running;

- V) work on the system is allowed only with the engine turned off and the ignition off;

- G) connection and removal of instrumentation is allowed only with the engine turned off and the ignition off;

- d) connection of control lamps to the terminals of the ignition coil is not allowed;

- e) do not crank the engine with a starter if all parts of the ignition system are not installed;

- and) do not take measurements with the engine running or cranking the engine with the starter if this requires connecting one of the wires to «mass» (-);

- h) Do not connect high voltage wires to «weight» (-).

Defective parts of the ignition system can cause engine malfunctions.

If the engine is running poorly, then the cause may be a malfunction of the crankshaft position sensor, ignition coil or control unit.

If the engine does not run at all, but the basic functions of the ignition system are in order, then the failure of the automatic ignition timing may be the cause of the engine failure. Such a failure can only be detected and corrected by a workshop, because in this case, instrumentation is needed, with the help of which a corresponding diagram is drawn up, which allows you to quickly detect an error in the settings.

In general, the ignition system is designed for a long service life and requires no maintenance. You just need to change the spark plugs regularly.