Vehicles with 2.1L XUD series engines

11. Move the tension roller behind the square 6 (see illustration 3.4).

12. Install thrust pin «A» (see illustration 3.4).

13. Lay the belt over the accessory pulleys and corresponding rollers.

14. Turn the tension roller 4 clockwise to release the thrust pin «A» from hole 5 (see illustration 3.4).

15. Tighten the bolt 3 fastening the tension roller with a force of 50 Nm.

16. Remove thrust pin «A» (see illustration 3,4).

17. Rotate the crankshaft four turns in the direction of engine rotation.

18. Make sure the thrust pin is «A» enters hole 5 freely. Otherwise, repeat the installation procedure.

19. Further, the installation of the dismantled components is carried out in the reverse order of removal.

20. Tighten the wheel bolts to 90 Nm.

Vehicles with 2.5L DK5ATE engine, power steering and air conditioning

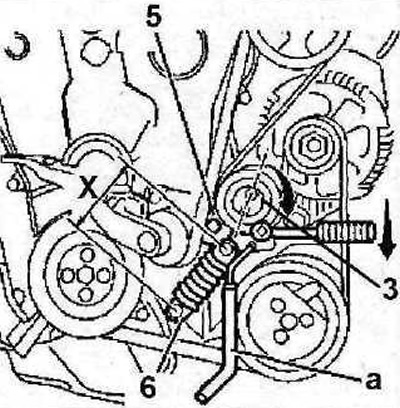

21. Check the ease of movement of rollers 3 and 4 (see illustration 3.7).

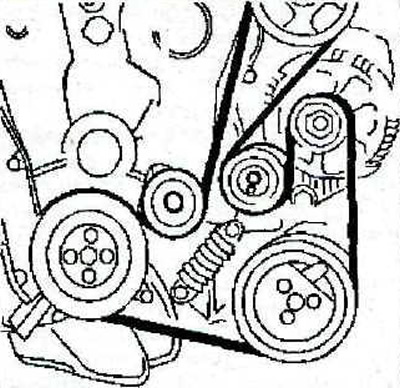

22. Lay the belt carefully over the accessory pulleys and corresponding rollers (see illustration).

3.22 Lay the belt carefully over the accessory pulleys and their respective rollers

23. Adjust the tension of the accessory drive belt. If a new belt is being installed, move roller 3 so that the thrust pin can be removed «A» (see illustration)

3.23 Adjust the tension of the accessory drive belt. If a new belt is being installed, move roller 3 so that the thrust pin can be removed «A»

24. Tighten the roller mounting bolt 3 with a force of 32 Nm

25. Rotate the crankshaft five revolutions in the direction of engine rotation.

26. Check the belt tension: if the thrust pin «A» with a diameter of 2 mm freely enters the corresponding hole (see illustration 3.23), the belt is tensioned correctly. Otherwise, repeat the adjustment procedure.

27. If the old accessory drive belt is installed, then measure the length X of the dynamic tensioner 6 (see illustration 3.23). If the distance X is less than 95 mm, then the belt is tensioned correctly (properly). If the distance X exceeds 95 mm, the tension adjustment procedure must be repeated, or the belt must be replaced.

28. Further, the installation of the dismantled components is carried out in the reverse order of removal.