- A) interruptions in ignition;

- b) knocking in the cylinder or in several cylinders;

- V) engine overheating;

- G) reducing the effective power of the engine;

- d) the appearance of excessive black smoke from the exhaust pipe;

- e) increase in fuel consumption,

- and) blue exhaust gas when starting a cold engine.

An inoperative injector can be determined by loosening the union nuts on the high pressure fuel lines on each injector in turn. The engine must be running at idle. If, when the fuel line nut on the next injector is loosened, the engine still continues to operate with the same noise or knocks, then this particular injector is faulty.

Injectors should be checked for leaks and repaired by a workshop. These works cannot be done on your own, because they require special tools. In addition, there is a risk of injury due to unprofessional performance of the specified work.

Depending on the type of engines of the power system, nozzles of different types are installed.

The injector mounted on the 4th cylinder has a needle stroke sensor designed to determine the start of fuel injection. The signal from this sensor is sent to the electronic control unit for the injection system.

Attention! On DK5ATE engines, the nozzle of the 3rd cylinder is equipped with an injector needle stroke sensor.

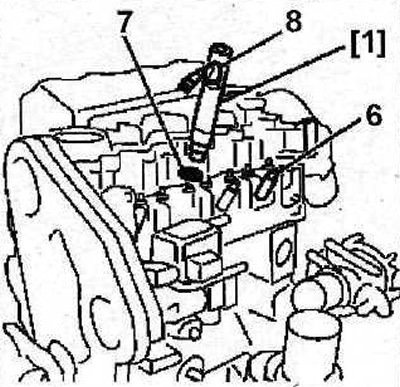

Access to the nozzles is difficult and therefore some parts must be dismantled to remove them. The injectors are located next to the glow plugs and protrude from the mount on the cylinder head (see illustration 2.0)

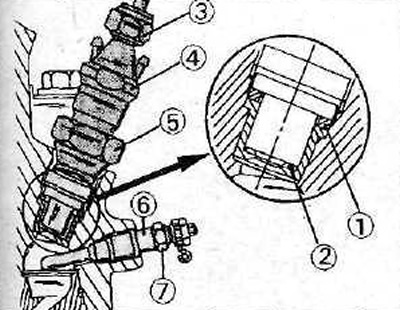

2.0 Mounting the injector on the engine

1 - copper ring

2 - heat shield

3 - union nut

4 - nozzle

5 - hexagon nut 27 mm

6 - glow plug

7 - hex nut of the glow plug

XUD Series Diesel Vehicles

Removing

1. Disconnect the wire terminal «masses» (-) from the battery.

2. Unscrew the union nut of the high pressure fuel line of the corresponding injector and move the fuel line to the side. You can use a regular wrench to unscrew the union nuts, but do not allow the wrench to slip on the nut.

3. Disconnect fuel return lines.

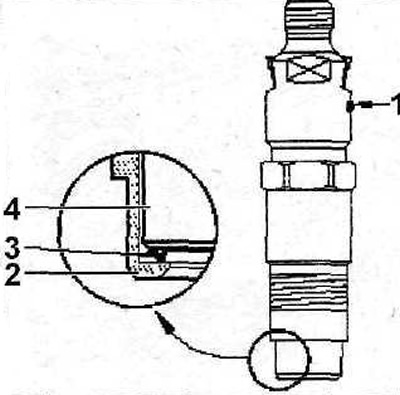

4. Unscrew the nozzle with a 27 mm socket. Remove the copper sealing ring 2 nozzles and heat shield 3 (see illustration).

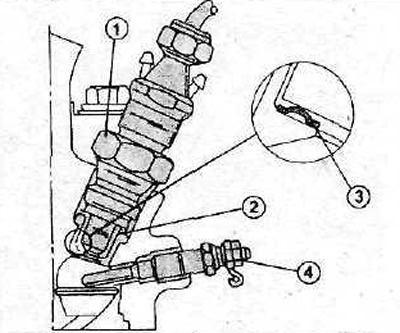

2.4 Unscrew nozzle 1 using a 27 mm socket wrench

2 - copper sealing ring

3 - heat shield

Installation

Injector installation sequence is reverse to removal.

5. Install a new O-ring, heat shield and screw in the nozzle (see illustration).

2.5 When installing the nozzle, the heat-shielding pad must be laid with the convex side up

1 - nozzle

2 - copper sealing ring

3 - heat shield

4 - glow plug

6. Tighten the nozzle with a torque of 90 Nm. The union nuts of the fuel lines are tightened with a torque of 20 Nm. When tightening the union nuts, do not damage the hexagon of the nut.

Vehicles with DK5ATE engine

Removing

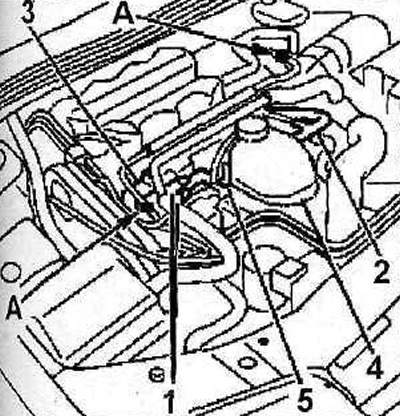

7. Disconnect at points A the pipeline of the hydraulic booster of a steering, and also plugs 1 (see illustration).

2.7 Disconnect the power steering line at point A

8. Remove the bracket 3, and also move the expansion tank 4 of the coolant to the side together with its bracket 5 (see illustration 2.7).

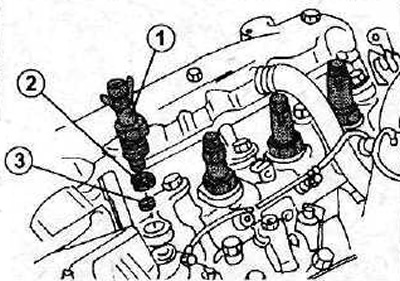

9. Remove the holders 6 of the injectors, and then with the head [1] unscrew the injectors themselves and remove the gaskets 7 (see illustrations 2.9 and 2.9a). Sealing gaskets must be replaced with new ones when installing nozzles.

2.9 Unscrew the injectors with the socket [1] and remove the seals 7

6 - holder

2.9а Fuel injector for DK5ATE engine

7 - white color marking

2 - holder

3 - thermal protective pad. Located inside the nozzle

4 - nozzle

Attention! When removing the injector of the third cylinder, do not damage the wire and plug 8 of the injector needle stroke sensor (see illustration 2.9).

The injectors are installed in the reverse order of their removal. Torque for injectors 55 Nm.