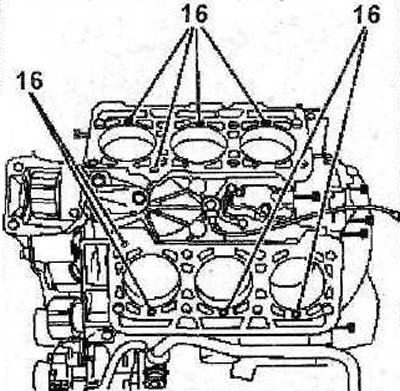

22. Clean the holes 16 for the cylinder head bolts (see illustration).

6.22 Clean the holes 16 for the cylinder head bolts

Attention! There must be no oil or coolant in the cylinder head bolt holes. If necessary, remove oil or liquid from the holes with a screwdriver wrapped in a rag. If oil remains in the holes, the cylinder block may be damaged when the bolts are tightened.

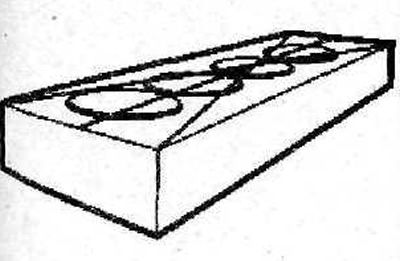

23. Check up a head of the block of cylinders on absence of deformation and buckling by means of a reference steel ruler. Set the ruler along the lines of measurement (see illustration). Curvature within 0.05 mm is allowed.

6.23 Check the cylinder head for deformation and warpage using a standard steel ruler. Set the ruler along the lines of measurement

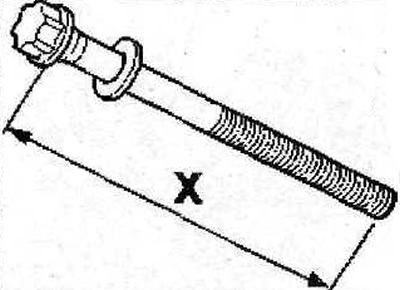

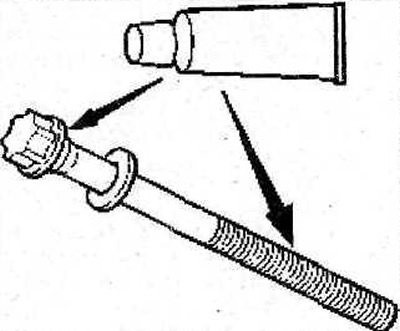

24. Measure the length of the cylinder head bolts. The length X of the bolt must not exceed 149.5 mm (see illustration)

6.24 Measure the length of the cylinder head bolts. The length X of the bolt must not exceed 149.5 mm

25. Clear a carving of bolts of fastening of a head of the block of cylinders, if necessary, renew a carving.

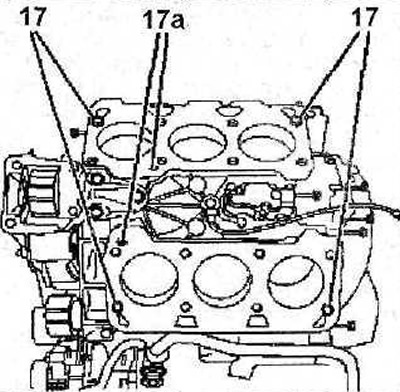

26. Make sure that the dowel pins 17 are present, holes 17a must be clean and dry (see illustration).

6.26 Make sure that the dowel pins 17 are present, holes 17a must be clean and dry

27. Lay new linings on heads of the block of cylinders; the gaskets must lie so that no openings are covered.

28. Install the cylinder heads.

29. Install the timing belt (see relevant chapter).

30. Apply a light coat of MOLYKOTEG RAPIDPLUS to the threads and underside of the cylinder head bolt head (see arrows in illustration).

6.30 Apply a light coat of MOLYKOTE G RAPID PLUS to the threads and underside of the cylinder head bolt head (see arrows)

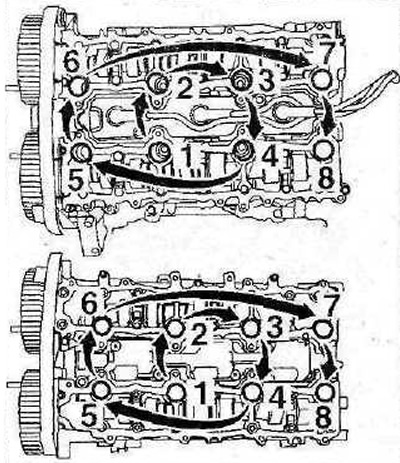

31. Tighten the cylinder head bolts in several passes in the sequence shown in the illustration:

- 1st pass - tighten the bolts with a force of 20 Nm;

- 2nd pass - completely loosen the bolts;

- 3rd pass - tighten the bolts with a force of 15 Nm;

- 4th pass - Tighten the bolts 225°.

Attention! Cylinder head cover gaskets are composite: minor gasket damage can be repaired by applying SILICONE CATEGORIE 2 sealant.

6.31 Cylinder head bolt tightening sequence

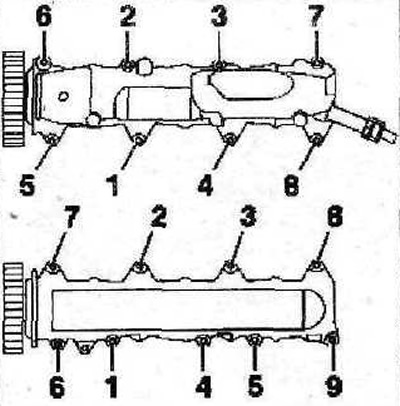

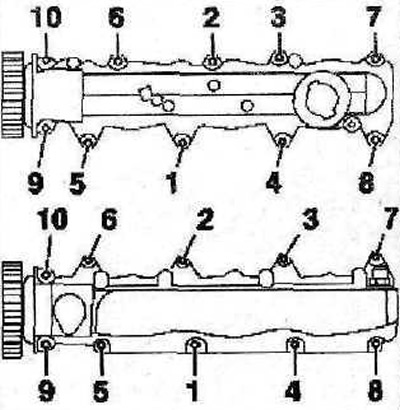

32. Establish covers of heads of the block of cylinders, tighten bolts of their fastening for several passes in the sequence specified in illustrations 6.32 and 6.32a:

- 1st pass - tighten the bolts by hand;

- 2nd pass - tighten the bolts with a force of 5 Nm;

- 3rd pass - tighten the bolts to 10 Nm.

6.32 The sequence of tightening the bolts for fastening the cover of the right cylinder head

6.32a The sequence of tightening the bolts of the cover of the left cylinder head

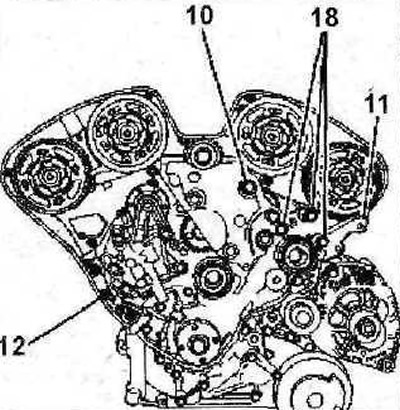

33. Screw in the M8 bolt 12, then install the bracket 11 of the power steering pump and tighten the bolts 18 of its fastening with a force of 39 Nm (see illustration).

6.33 Screw in the M812 bolt, then install the bracket 11 of the power steering pump and tighten the bolts 18 of its fastening with a force of 39 Nm

34. Screw in the bolt 10 and tighten it with a force of 60 Nm (see illustration 6.33).

35. Install the dipstick guide tube.

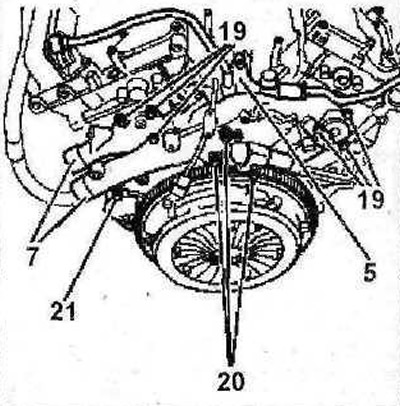

36. Connect hoses 5 for crankcase ventilation, supply and return hoses 7 to the thermostat housing. Tighten bolts 19 and 21 to 8 Nm, bolts 20 to 25 Nm (see illustration).

6.36 Connect crankcase ventilation hoses 5, supply and return hoses 7 to the thermostat housing. Tighten bolts 19 and 21 to 8 Nm, bolts 20 to 25 Nm

37. Further, the installation of the dismantled components is carried out in the reverse order of removal.