On vehicles with a manual transmission, the clutch is the link between (and divisive) engine as a source of torque with the rest of the drive parts. At the moment of starting the movement, the clutch gently transfers the torque from the running engine to the still stationary parts of the drive. Thus, increased wear of gears and joints is prevented.

The diameter of the clutch discs and the pressing force of the driven disc depend on the engine power. Not all car models are fitted with the same clutch design. For this reason, when ordering spare parts, please state the engine type and serial number. The diameter of the clutch discs may also vary depending on the vehicle model.

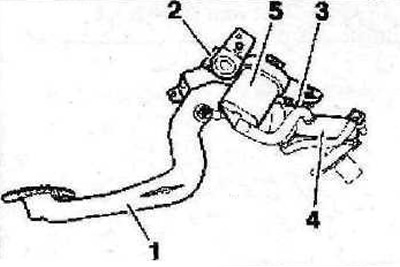

The clutch consists of the following main units (see illustration 1.0):

- A) clutch drive, which includes the clutch pedal, clutch master and slave cylinder - for hydraulically actuated clutch - or clutch cable, as well as the clutch release fork and release bearing;

- b) the actual clutch, which consists of a driven (frictional) disc, clutch cover with pressure plate and diaphragm spring.

1.0 Hydraulic clutch parts

1 - clutch pedal

2 - clutch pedal bracket

3 - spring

4 - clutch master cylinder

5 - reservoir with brake fluid

The pressure plate is rigidly screwed to the flywheel. The clutch disc is clamped between the pressure plate and the flywheel by the force that the central diaphragm spring creates and is centered by the gearbox input shaft.

Friction linings are riveted on both sides of the driven disk. Each time the clutch is engaged and disengaged, the friction linings gradually wear out due to light friction. Thus, the clutch disc is a wear part. The degree of wear depends on the load (trailer operation) and driving style. The clutch itself is self-adjusting and requires no maintenance.

When you press the clutch pedal, the drive cable is pulled and the clutch release fork presses the release bearing against the diaphragm spring. The pressure plate moves away from the flywheel, and the driven plate rotates freely. Thus, the power circuit between the engine and the gearbox is disconnected. As soon as the clutch pedal is released, the diaphragm spring returns the disc to the flywheel, thereby pressing the driven disc and restoring the power circuit.

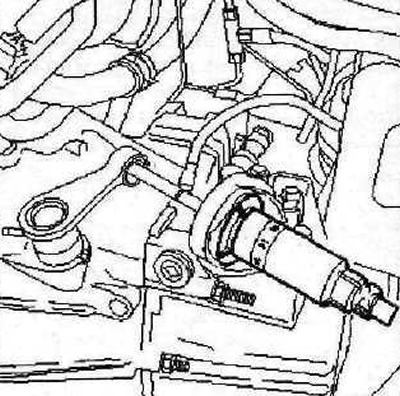

The hydraulically actuated clutch slave cylinder is attached to the gearbox housing (see illustration 1.0a).

1.0a Clutch slave cylinder

When you press the clutch pedal, the force of the driver's foot is transmitted through the rod and the fluid piston, which, in turn, transfers pressure from the master cylinder piston to the slave piston. Further, the rod of the working cylinder actuates the release fork, which pushes the release bearing forward, which leads to the indentation of the diaphragm spring inward, and it removes the pressure plate from the clutch disc.

When the clutch pedal is released, the diaphragm spring pushes the driven plate forward, which is pressed against the flywheel and, as a result, is sandwiched between the pressure plate and the flywheel.

The hydraulic clutch system runs on brake fluid. The hydraulically actuated clutch is automatically adjusted.