Brake discs

Brake discs can be reworked as long as they are not ground or machined to the minimum allowable thickness. If the brake disc wears to a minimum thickness, it must be replaced with a new one. When checking the thickness of the disc, you should be guided by the specifications.

The working surface of the brake disc must also be checked for axial play without removing it from the vehicle.

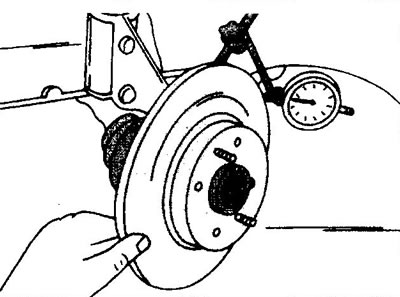

19. Fix the dial indicator with the holder on the wheel suspension so that the measuring pin is approximately 2 mm from the outer edge of the disc (see illustration).

2.19 Checking the axial runout of the brake disc

20. Spin the disk. When the brake disc is rotated, the indicator needle should not deviate by more than 0.15 mm.

Assuming that the brake disc is sufficiently worn and has reached its maximum allowable thickness, this can be checked without removing the brake disc from the vehicle.

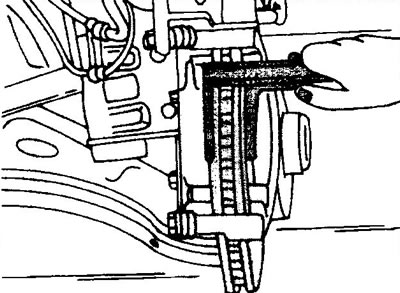

21. Measure the brake disc thickness with a micrometer. Due to the fact that the surface of the brake disc wears unevenly, the measurement should be carried out at several points around the entire circumference of the disc (see illustration).

2.21 Measurement of the residual thickness of the brake disc without dismantling the disc from the vehicle. The illustration shows a ventilated brake disc

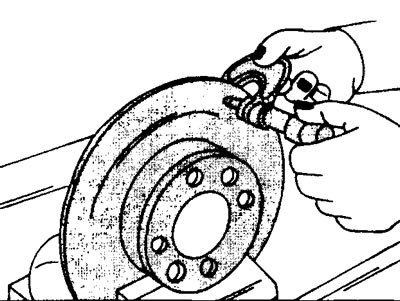

The permissible total deviation must not exceed 0.025 mm. Nominal values are indicated in the specifications. If the brake disc has been removed, the remaining thickness can be checked by holding the disc in a vise (see illustration 2.0a).

2.0a Measurement of the residual thickness of the brake disc removed from the vehicle.

In order to remove the brake disc from the car, you should dismantle the brake pads by first removing the caliper, as well as the pad guide. Removal of the brake disc mechanism with a fixed caliper is possible without dismantling the guide pads.

22. Turn out bolts of fastening of a brake disk and remove it. The tightening torque for the bolts is 25 Nm. If the brake disc is firmly seated on the hub, it can be knocked down with a rubber mallet.

Installation of the brake disc is carried out in reverse order.

23. Install the shoe guide and tighten the mounting bolts with the appropriate torque (see specifications).

24. Install the brake pads.

25. Carry out a test drive and check the operation of the brakes. Be careful. The brakes need to run in, which takes some time.