14. Lay the belt over the pulleys. Make sure the belt fits exactly into the grooves on each pulley. Further actions depend on the type of engine installed on the vehicle.

Car with 1.8 and 2.0 liter petrol engine (8 valves)

15. Make sure roller 2 is (see illustration 3.4), as well as rollers 1 and 2 (see illustration 3.7) have free movement. For proper belt tension, the already mentioned belt tensioner is required (see illustration). In the absence of a tool, the tension is carried out taking into account the steps below, followed by tension adjustment in the workshop.

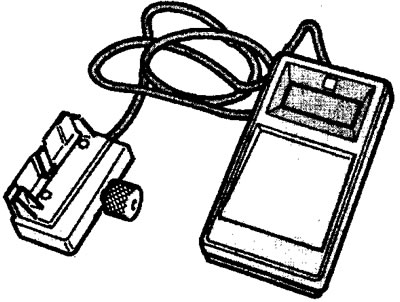

3.15 A device for measuring the tension of the generator drive belt. The device is placed on the belt and fixed with a locking bolt

Vehicles without air conditioning

16. Loosen bolt 5 to tighten the belt, then tighten bolts 1 and 4 to 5 Nm (see illustration 3.4).

17. Rotate the crankshaft four turns and measure the belt tension. If the alternator belt tension does not correspond to the value of 60? 3 sim, then loosen bolts 1 and 4 and tighten bolt 5 so that the belt tension is within the required limits. Then tighten bolts 1 and 4 with a torque of 20 Nm (see illustration 3.4).

Attention! The above value applies only to a new belt. If the old belt is installed, then its tension is carried out within 45 sim. The alternator belt tensioner shown in illustration 3.15 is available in two versions. If such a device is not available, then the belt is tensioned on the basis of experience, and then the tension is checked in the workshop. Experienced mechanics can easily determine if the belt is properly tensioned.

18. Connect wire terminal «masses» (-) to the battery and start the engine. Let the engine run for about 10 minutes and check the alternator belt tension.

Cars with air conditioning

19. Install belt tensioner 5 (see illustration 3.7). Lubricate bolts 3 with a protective agent before installation «Loctite» and tighten to 20 Nm.

20 Press the belt tensioner 5 to the side with the help of a square, as shown by the arrow in illustration 3.7, to release and remove the socket wrench from the hole «A».

21. Release the belt tensioner so that it tensions the belt. No other belt adjustments are needed because the belt tension is automatic.

2.2 Install all other parts in the reverse order of removal.

Vehicles with 2.0 liter engine (16 valves)

The installation of the belt in cars with this type of engine and air conditioning is carried out in the same way as in cars with 8-valve engines.

For cars without air conditioning, it is necessary to tighten the bolts I by hand and install the belt tensioner 7 in section 6, as shown in illustration 3.9.

23. Tighten bolt 2 so that the meter reads 120 sims when the new belt is installed. When installing the old belt, the reading should be 90 sims. As soon as the device shows the desired tension value, tighten the bolts 1 with a torque of 20 Nm (see illustration 3.9).

24. Remove the belt tensioner and rotate the crankshaft in the direction of engine rotation. Check belt tension. If necessary, correct it by loosening bolts 1 and tightening bolt 2.

25. Install all remaining parts in the reverse order of their removal.

Diesel vehicles without air conditioning

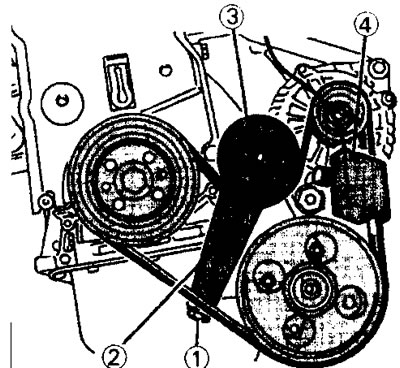

26. Fix the device 4 for measuring belt tension as shown in the illustration. Screw 1 must not be tightened (see illustration).

3.26 Alternator belt tension for vehicles with a diesel engine without air conditioning.

1 - adjusting screw

2 - fastening bolt. Tightening torque 22 Nm

3 - fastening bolt. Tightening torque 22 Nm

4 - a device for measuring belt tension

27. Tighten screw 1 until the meter shows a belt tension of 115±10 sims. Then tighten bolts 2 and 3 and remove the device.

28. Turn the crankshaft in the direction of engine rotation and check the belt tension. Correct it if necessary.

29. Remove the belt tension measuring device if tension adjustment was necessary and install all other parts in the reverse order of their removal. Cars with a diesel engine and air conditioning

30. Lay the belt, guided by illustration 3.11, on all pulleys and rollers. Make sure the belt is in the grooves.

31. Turn the tension roller 5 to the right so that the rod 2 can be removed to rotate the belt tensioner from the hole 6 (see illustration 3.11).

32. Tighten bolt 4 to 50 Nm without changing the position of the belt. The belt tension is sufficient and no adjustment is needed.

33. Turn the crankshaft four turns and make sure the belt is tensioned correctly. If so, then the rod 2 for turning the tensioner can be freely inserted into the hole 6 (see illustration 3.11).

34. Reinstall all other parts in the reverse order of removal.

Attention! If you do not have a belt tension measuring device at your disposal, it is recommended that you contact a workshop to check the tension of a self-installed belt.