Forced circulation of the coolant is carried out using a water pump, which is driven by a timing belt. The water pump pumps coolant into a sufficiently large number of channels and hoses.

Cooling of the heated liquid is provided by a radiator having a sufficiently large liquid distribution area. The cooling of the liquid in the radiator occurs due to the oncoming air flowing around the radiator cooling fins. With an increase in the load on the engine and, accordingly, a greater heat transfer, the liquid is additionally cooled by an electric radiator fan. On vehicles with diesel engines, as well as those equipped with air conditioning, two fans are installed. The radiator fan is turned on by a thermal switch located on the underside of the radiator.

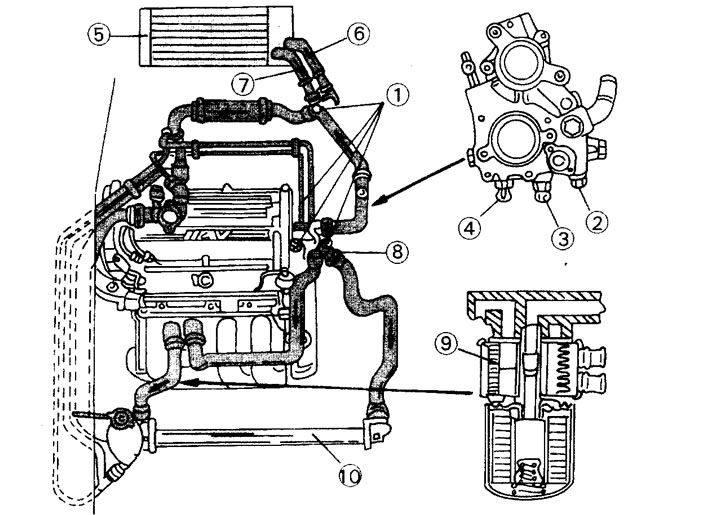

In order for the coolant to quickly reach the required operating temperature, the cooling system is divided into small and large circuits. The inclusion of a large circuit of the circulation of the coolant is carried out by a thermostat, which is a thermoelement filled with wax and equipped with a spring that provides the necessary movement of the valve plates, thereby opening or closing the large circuit.

During the engine warm-up period, a thermostat-controlled valve closes the coolant from entering the radiator. The bypass valve immediately directs the flow of coolant to the water pump, which pumps coolant into the engine cooling jacket. The circulation of the coolant in such a circuit contributes to the rapid warming up of the engine.

As soon as the temperature of the coolant rises to 85-100°C, the thermostat gradually opens the large circuit valve, directing the liquid to the radiator. There is a mixture of cold liquid from the radiator with hot liquid from the engine, and only after that the liquid again enters the engine cooling jacket. This way the hot engine is not exposed to the cold coolant.

To increase the cooling effect, as the coolant heats up, an increased pressure is created in the cooling system, reaching almost 1.0 bar. This pressure is provided by a corresponding valve in the cap of the expansion tank. Increased pressure in the system increases the boiling point of the coolant. If the permissible level of pressure in the system is exceeded, the exhaust valve opens on the cover of the expansion tank and the excess pressure is released.

Over time, the anti-corrosion effect of the coolant decreases, so the liquid itself must be replaced with a new one.

The cooling circuit of vehicles with diesel engines includes an oil cooler installed between the oil filter and the cylinder block. The oil cooler is connected to the cooling system by two hoses. There is a diesel fuel heater on the coolant outlet pipe, which makes it easier to start the diesel engine in cold weather.

Attention! The radiator fan may also turn on when the engine is off. This is especially true immediately after turning off the engine. For this reason, care must be taken when working in the engine compartment near the fan.

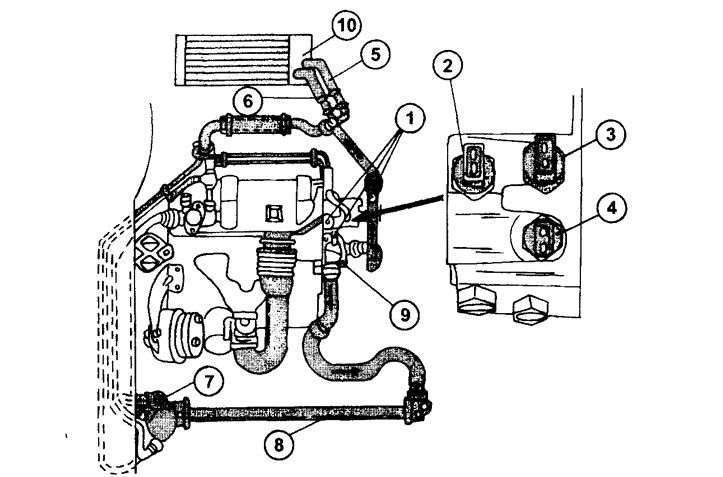

1.0 Cooling system diagram for 1.8 liter XU7 engine or XU10J engine without air conditioner

1 - air vent plugs

2 - coolant temperature sensor

3 - thermal switch

4 - coolant temperature sensor

5 - heater radiator supply hose

6 - heater radiator outlet hose

7 - expansion tank

8 - radiator and radiator fan

9 - thermostat

10 - heater radiator

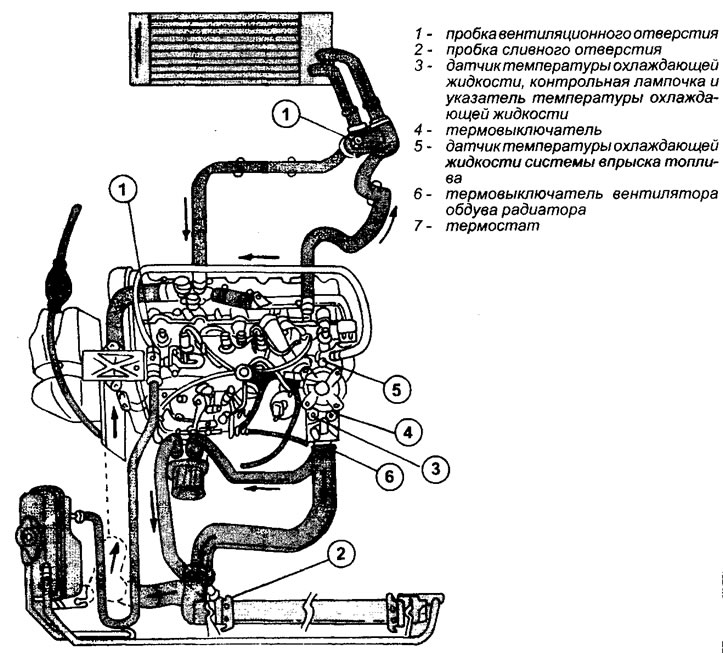

1.0a Coolant circuit for 1.9L diesel engine with turbocharger

1.0b Coolant circuit of a 2.0L vehicle with automatic transmission

1 - air vent plugs

2 - thermal switch

3 - thermal switch

4 - coolant temperature sensor

5 - heater radiator supply hose

6 - heater radiator outlet hose

7 - expansion tank

8 - radiator and radiator fan

9 - thermostat

10 - oil cooler outlet hose

11 - oil cooler supply hose

12 - oil cooler

13 - heater radiator

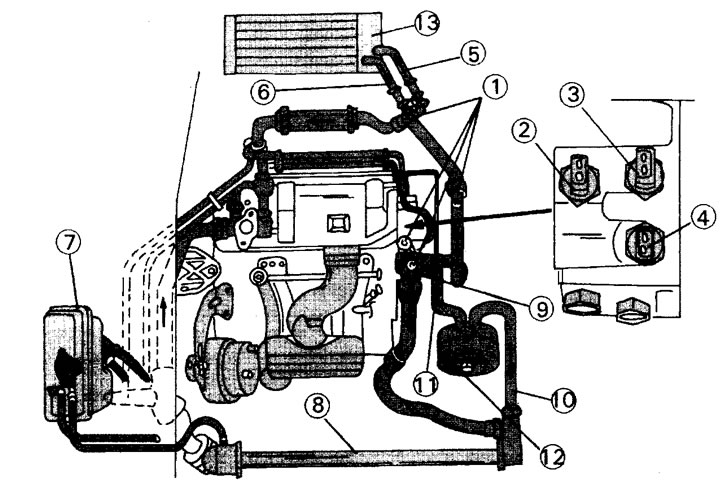

1.0v Scheme of the cooling system of a 2.0-liter gasoline engine with 16 valves

1 - air vent plugs

2 - thermal switch

3 - thermal switch

4 - coolant temperature sensor

5 - heater radiator

6 - heater radiator supply hose

7 - heater radiator outlet hose

8 - thermostat

9 - oil cooler

10- radiator and radiator fan