Removing

The cylinder head can be removed without removing the engine from the vehicle. However, keep in mind that the toothed belt will have to be partially removed. It must also be taken into account that the new head gasket must be the same thickness as the old one. If the removal of the cylinder head is due to the need to replace valves, prechambers or other parts, then we recommend entrusting the work to a workshop. The disassembly and overhaul of the gas distribution mechanism indicated for gasoline engines is generally applicable to this type of diesel engine.

All engines

1. Disconnect the wire terminal «masses (-) from the battery.

2. Install the front of the car on the goats and remove the engine mudguard.

3. Remove the ribbed belt to provide better access to the engine. This is especially true for 2.1 liter engines.

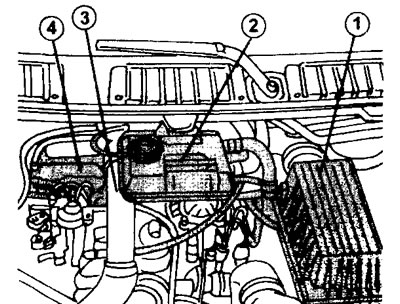

4. Remove the air filter along with the hoses (see illustration).

20.4 Remove the air filter and the following parts

1 - air filter

2 - coolant expansion tank

3 - air intake sleeve

4 - cylinder head cover

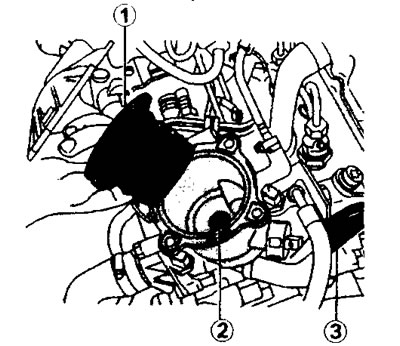

Next to the hose there is an eyelet 3 for lifting the engine (1.9 liter engine), to be disconnected (see illustration 20.5).

20.5 Remove the replaceable filter element 1 of the fuel filter and unscrew the bolt that secures the lower part of the filter

5. Remove the fuel filter element and remove the bolt that secures the bottom of the filter (see illustration)

6. Remove the cylinder head cover.

7. Turn out bolts of fastening and disconnect a final branch pipe together with a lining.

8. Disconnect from a head of the block of cylinders all wires, hoses and pipelines.

9. Drain the coolant.

10. Disconnect a reception pipe of mufflers from a turbocharger.

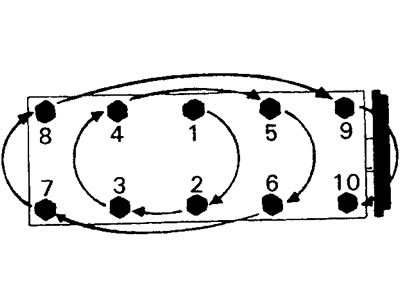

11. Release the power wire of the EGR system, unscrew the nuts that secure the gas turbine supercharger and remove it.

12. Disconnect the intake manifold and remove it by moving up (see illustration)

20.12 Release the EGR power cable, unscrew the nuts that secure the gas turbine supercharger and remove it, and also disconnect and remove the intake manifold. The illustration shows a 1.9 liter engine

13. Release the engine mounts from the cushions to transfer the weight of the engine to the front mount. After that, disconnect the right engine mount bracket.

14. Remove both toothed belt guards.

15. Lock the crankshaft from turning with a rod if the 1.9 liter engine is disassembled by installing it as shown in illustrations 17.77. Before this, the crankshaft must be rotated to set the engine to TDC.

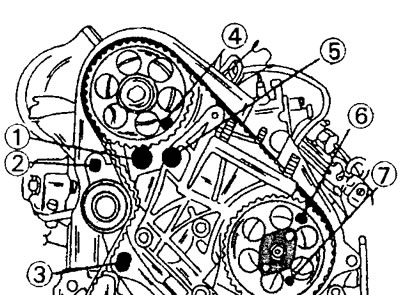

16. Prepare three M8x1.5 mm bolts, 40 mm long. Insert one bolt into hole 4 on the camshaft gear, and the other two into holes 6 and 7 on the injection pump gear (see illustration).

20.16 Front side of the engine after removing the toothed belt guards.

1 - hole for the square on the toothed belt tensioner

2 - toothed belt tensioner bolt

3 - toothed belt tensioner bolt

4 - thrust bolt in the hole of the camshaft gear

5 - engine mount bracket bolt

6 - thrust bolt in the hole of the injection pump gear

7 - thrust bolt in the hole of the injection pump gear

These bolts are fairly easy to install if the crankshaft is properly installed. Installing bolts allows you to fix the gas distribution mechanism.

17. Turn out both bolts 2 and 3 fastening the toothed belt tensioner and, inserting a 3/8 inch square wrench into hole 1 of the tensioner, press the tension roller out to loosen the toothed belt tension. Bolt 2 tighten again to fix the tensioner in its new position (see illustration 20.16).

18. Remove the toothed belt from the gears, feeding it forward.

19. Loosen the timing belt gear bolt on the camshaft and remove the gear from the shaft. Keep the gear from turning.

20. Turn out for several passes in reverse order to screw in the bolts of the cylinder head. The length of the bolts before their subsequent installation during assembly must be measured. Stretched bolts must be replaced with new ones (see illustration).

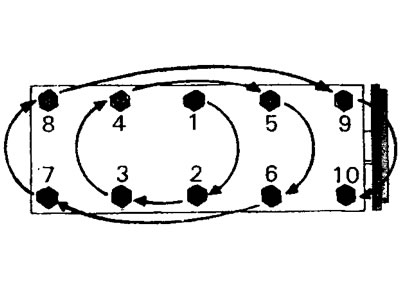

20.20 The sequence of screwing in and tightening the cylinder head bolts. When removing the head, the bolts are turned out in reverse order

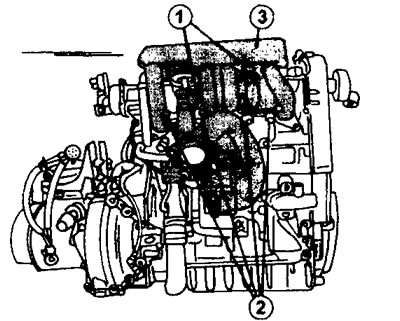

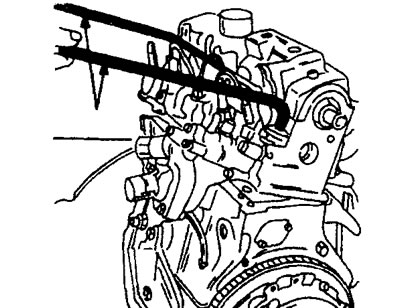

Due to the fact that the cylinder head is mounted on a centering pin, it is quite difficult to separate the head from the cylinder block. In workshops, mounts with ends bent at an angle of 90°are used to remove the head. Both mounts, the bent ends of which are inserted into the holes for the mounting bolts, are lifted simultaneously. The raised cylinder head is shifted slightly to the side to bring the camshaft out of the bearing. Make sure the dowel pin remains in the cylinder block. If the pin is removed together with the block head, then it must be pulled out of the head and inserted into the cylinder block (see illustration 20.20a).

20.20a To remove the cylinder head, use pry bars with ends bent at an angle of 90°.

21. Clean the mating surfaces of the head and cylinder block with an appropriate cleaner. Surfaces must not be cleaned with a hard scraper or abrasive paper. Grinding of the cylinder head is also not allowed. If the camshaft rotates freely, then it does not need to be modified.

After dismantling the cylinder head, remove the relevant parts and remove the valves (see relevant chapter).

Installation

22. Clean the holes for the cylinder head bolts. The holes must be free of oil and the threads must be in good condition. If necessary, the thread can be updated with an appropriate tap (thread M12x150). Surfaces of contact of a head of the block of cylinders and the block of cylinders have to be carefully cleaned.

23. Install the camshaft at TDC. This means that the valves of cylinders #1 and #4 must be in the closed position.

24. Install in the left corner (when viewed from the front) cylinder block centering pin. In the opposite corner of the block, screw in the centering pin. This finger after installation of a head of the block of cylinders is unscrewed by means of a screw-driver.

25. Select a gasket that is the same thickness as the previous one. Lay the gasket on the cylinder block so that the tab with the gasket marking is facing the desired direction. When purchasing a new gasket, it is recommended to present the old one.

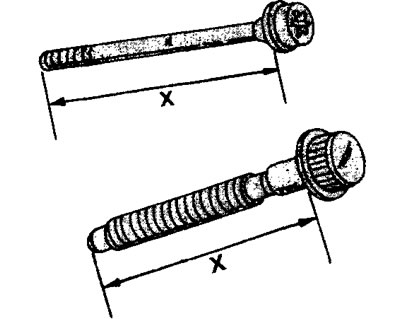

26. Measure the length of the cylinder head bolts. The head of the XUD9 engine cylinder head bolts is designed for a socket wrench. On other engines, cap screws may be used. The measurement of the bolt length is carried out on the segment X (see illustration).

20.26 Bolt length measurement is taken on line X. The top bolt without shoulder is used on 1.9 liter engines and the bottom bolt is used on 2.1 liter engines

When measuring bolts, it must be taken into account that bolts without a shoulder at the lower end can be used (motors XUD9 and XUD11) or with ledge (XUD11). If the bolt length without shoulder is greater than 146.8 mm (see illustration 20.26), then such bolts must be replaced with new ones.

The same applies to shoulder bolts if their length is over 151.5 mm (see illustration 20.26).

27. Install the cylinder head. Place the head slightly at an angle so that the centering pin falls into the corresponding hole in the cylinder head. After that, completely release the head so that it is installed on the cylinder block. The auxiliary centering pin must now be unscrewed with a screwdriver.

28. Lubricate the bolt threads and washers with oil and screw the bolts into the holes. A socket wrench is used to screw in the cylinder head bolts (XUD9 engines) or special key (XUD11 engines). In addition, you will need a goniometer to tighten the bolts.

29. Tighten the bolts in sequence as shown in (illustrations 20.29).

20.29 Tighten the cylinder head bolts in sequence

The procedure for this is as follows.

30. Screw in the shown sequence all the bolts with a torque of 20 Nm, and then tighten them with a torque of 60 Nm.

31. Tighten all bolts at an angle of 180°, i.e. half a turn. Dovorot can be done with the help of a collar.

Subsequent tightening of the cylinder head bolts is not necessary.

32. Install the toothed belt gear onto the camshaft. Fasten the pinion to the shaft with a bolt with a tightening torque of 45 Nm, while holding the pinion from turning.

33. Adjust valve clearance (see relevant chapter). Valve clearance is adjustable only on 1.9 liter engines.

34. Reinstall the toothed belt.

All other parts are installed in place in the reverse order of removal.