The engine is assembled in the reverse order of disassembly, identical to the assembly of a 1.9-liter engine. After installing the crank mechanism and the oil pump, proceed as follows.

Oil pump - installation

1. Install a new dry seal if the vehicle is not equipped with air conditioning.

2. Screw in the 23 oil pan mounting bolts, observing the markings made during removal, and evenly tighten them to a torque of 16 Nm (see illustration 17.59). The four sump bolts on the flywheel side have a socket head.

3. Screw in the sensor of the engine oil level indicator with a tightening torque of 10 Nm.

The aluminum oil sump fitted to vehicles with air conditioning is installed using a dowel pin on the crankcase. A sealing gasket for the pallet is not needed, however, the mating surfaces are lubricated with sealing mass. The pallet mounting bolts are screwed in in accordance with the marks made during removal and tightened with a torque of 16 Nm (see illustration 17.0).

4. Install the flywheel on the crankshaft.

5. Fix on a flywheel conducted and clamping disks of coupling. The tightening torque of the fastening bolts is 20 Nm.

6. Install the oil cooler with the coolant hose fittings facing up. Screw on the union nuts and tighten them to a torque of 58 Nm. Also screw in the oil level indicator sensor with a torque of 39 Nm.

7. Lubricate the oil filter O-ring with engine oil and attach the oil filter to the oil cooler. After that, tighten the filter a quarter of a turn.

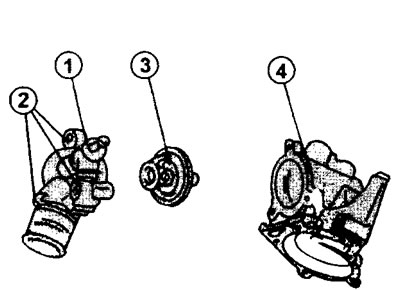

8. Install a new gasket between the thermostat housing and the water pump and tighten their fastening bolts to 20 Nm. Apply sealing compound to the flat surface of the thermostat housing and install the thermostat into the housing. Close the thermostat with a cover by screwing in the three mounting bolts and tighten them with a torque of 20 Nm (see illustration).

19.8 Outlet and thermostat housing

1 - thermostat housing cover

2 - bolts of fastening of a cover

3 - thermostat

4 - thermostat housing

9. Fix the thermostat case on the block of cylinders and fix with bolts with the moment of 20 Nanometers.

10. Install the water pump by tightening the six mounting bolts to 10 Nm.

11. Reinstall cylinder head covers (see relevant chapter).

Attention! Cylinder head gaskets are available in different thicknesses. The thickness of the gasket depends on the height of the protrusion of the pistons above the surface of the cylinder block. To determine the height of the protrusion of the pistons, they must be set in order to TDC and measure the protrusion. The procedure in this case is the same as for the 1.9-liter engine. Piston protrusion ratings and gasket designations are also the same (see relevant chapter).

12. Lubricate the working surface of the new oil seal and, putting it on the camshaft, press it into the hole on the cylinder head. After pressing the oil seal, install the toothed belt gear onto the camshaft. At the same time, do not allow the shifting of the key that secures the gear to the shaft.

13. Screw in the gear mounting bolt and, holding it from turning, tighten the bolt with a torque of 50 Nm.

14. Install the toothed belt tension roller and tighten the bolt of its fastening with a torque of 37 Nm.

15. Install the key in the hole on the crankshaft and put on the timing gear.

16. Lay a toothed belt and tighten it.

17. Install the injection pump. Screw in the high pressure fuel pump mounting bolts, as well as the bracket, but do not tighten them yet.

18. Establish a head of the block of the cylinder and tighten 11 bolts of fastening with the moment of 8 Nm.

19. Put the drive gear on the injection pump shaft and secure it with a bolt. Keep the gear from turning while tightening the bolt (see illustration 18.21). The tightening torque is 50 Nm.

20. Install the belt pulley on the crankshaft. Lubricate the thread of the pulley mounting bolt with protective grease «Loctite» and tighten the bolt to 70 Nm. Then tighten the bolt by 60°. Hold the crankshaft from turning by locking the flywheel.

21. Screw in glow plugs. The tightening torque of the spark plugs is 22 Nm. Fix the current-carrying busbar on the four contact pins of the candles and fix them with nuts, tightening them with a torque of 4 Nm.

22. Screw nozzles (tightening torque 90 Nm) and connect the high pressure fuel lines to them by screwing the union nuts with a torque of 20 Nm.

23. Establish protective casings of a gear belt.

The remaining parts are installed in the reverse order of disassembly. The tightening torque of the exhaust manifold nuts is 20 Nm, the intake manifold is 23 Nm.