If the adjustment is performed without dismantling the engine from the car, then it is necessary to remove the cylinder head cover in order to gain access to the valves.

1. Place the front of the car on a gantry and engage a high gear. In this position, it will be possible to turn the engine to adjust the valve clearance.

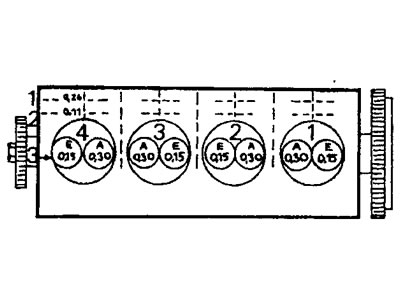

2. Draw a sign as shown in (illustrations 21.2),

21.2 Table for records when adjusting valve clearance.

Line 1 = valve clearance measured

Line 2 = difference after subtracting the nominal value from the measured value

Line 3 = nominal value

in order to then enter the values obtained during the check to correct the gap.

3. Turn the engine in the direction of travel using the free hanging wheel. To measure the valve clearance, the corresponding valve cam must point upwards. This means that the opposite valve of this cylinder is in position «Open». Cylinder number 1 is located near the flywheel. Valve clearance is measured using an appropriate gauge inserted between the back of the cam and the valve lifter.

4. Enter the value obtained in column I of the table. In this case, the resulting value is 0.26 mm (see illustration 21.2).

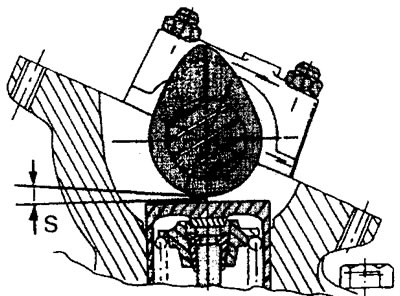

Turning the engine half a turn each time in the direction of travel, measure the clearance of all valves and record the values obtained. The nominal value of the intake valve clearance is 0.15 mm, exhaust -0.30 mm. If the value obtained does not correspond to the nominal value, then the gap must be corrected by installing shims of a different size between the valve lifters and the valve stem. If the clearance is greater than the nominal value, then thicker shims are installed. Reduced size - thinner (see illustration 21.4).

21.4 Measure gap S using a suitable gauge

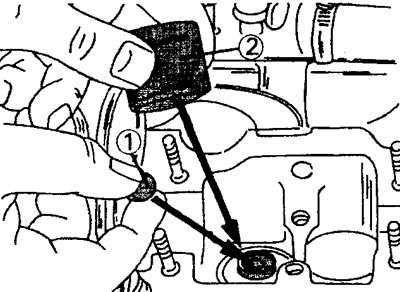

5. Remove the valve lifter and the shim underneath (see illustration).

21.5 Remove the valve lifter 2 and the shim 1 underneath

Clean the adjusting washer and measure its thickness.

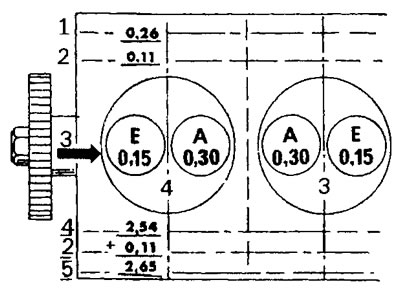

6. Determine the thickness of the new washer. The procedure is as follows: from the valve clearance obtained by measuring, it is necessary to subtract the nominal value (see illustration).

21.6 Calculate the thickness of the new washer to correct the valve clearance. E is for intake valves and X is for exhaust

Line 1 = valve clearance measured

Line 2 = difference after subtracting the nominal value from the measured value

Line 3 = nominal value

The clearance adjustment value can be either positive or negative. If the value is positive, a thicker shim must be installed. If the value is negative, then a thinner washer is installed. The average value of the permissible range of values is taken as the nominal value. The thickness of the new shim is determined by the sum of the measured value plus the correction value.

7. Select a new shim that is as thick as possible with the addition value. Shims are available in thicknesses from 2.425 to 3.550 mm. The thickness step is 0.075 mm. The washer must be free of grease before measurement and installation.

Attention! When replacing the camshaft or tappets, a 2.425 mm thick washer must always be installed (nominal value) regardless of the thickness of the washers that stood before replacement.

8. Lubricate the valve tappets and install them in place. After installation, the pushers must not be lifted. This can cause the shim to change its position. Therefore, if the installed pusher needs to be lifted, then it must be removed completely, re-install the shim, and then insert the pusher.

9. Establish a camshaft and carry out all works concerning installation of a gear belt.

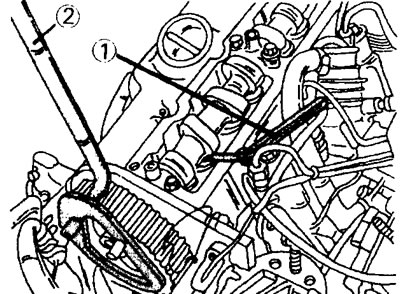

10. Turn the camshaft at least two turns. Rotate the shaft very slowly. At the same time, check the valve clearance again using a measuring template. Make any necessary adjustments if necessary (see illustration).

21.10 Checking the valve clearance using a measuring gauge 1. The camshaft can be rotated for this using the swivel device 2

11 Install all other parts in the reverse order of disassembly.