When removing the motor mount, the power unit must be secured to a beam or hoist.

XUD9 engines

1. Loosen the right front wheel nuts.

2. Jack up the right front side of the vehicle and place a stand under the body.

3. Remove the right wheel.

4. Disconnect the wire terminal «masses» (-) from the battery.

5. Remove the fender liner and noise insulation from the wheel arch.

6. Shift into gear and remove the belt pulley bolt from the crankshaft.

7. Remove the belt pulley. To do this, use two mounts or a puller.

8. Attach a cable or chain to the engine lifting eye and lift the engine with a hoist or equivalent. You can also install a garage lift under the engine with blocks of wood on top of it and carefully lift the engine up to relieve the mounts.

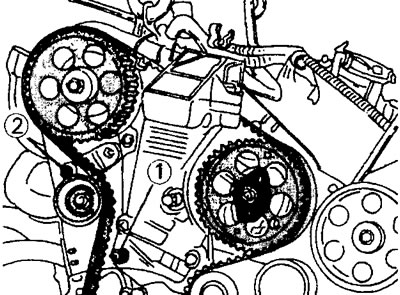

9. Remove the toothed belt guard. In this case, first feed the upper part forward and then up. Then release the second, lower, part of the casing from the pins and also remove it. Remove spacer (see illustration).

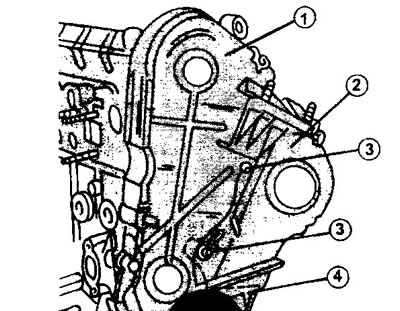

24.9 Attaching the toothed belt guard

1 - upper part of the protective cover

2 - lower part of the protective cover

3 - protective cover fastening pins

4 - spacer sleeve

10. Prepare two bolts MX x 1.25 and 40 mm long. Insert one bolt into the camshaft gear at point 1, and the second into the high pressure fuel pump drive gear at point 2 (see illustration).

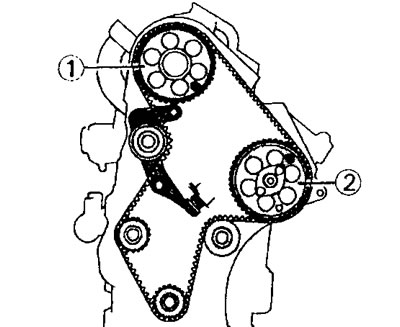

24.10 The procedure for blocking the gas distribution mechanism. The black dots mark the holes into which the pins are inserted

1 - camshaft gear

2 - drive gear of injection pump

Thus, the gas distribution mechanism is blocked. A general view of the gas distribution mechanism is shown in illustration 24.10a.

24.10a Timing mechanism parts

1 - toothed belt gear on the camshaft

2 - drive gear of injection pump

3 - eye for removing the engine

4 - engine support bracket

11. Loosen bolt 1 and nut 2 of the toothed belt tensioner (see illustration).

24.11 Toothed belt tensioner. 1.9 liter engine

1 - bolt

2 - nut

3 - hole for a square key

4 - pressure spring

Insert a 9.52 mm square wrench into hole 6 of the tensioner (3/8") (long handle with ratchet) (see illustrations 17.16 and 17.17). Turn the key to compress the tensioner spring.

12. Tighten bolt 2 to fix the toothed belt tensioner in the new position (see illustration).

24.12 Automatic toothed belt tensioner held by nut 1 and bolt 2

13. Remove the toothed belt from the camshaft gear, and then from the remaining gears. If this toothed belt is to be reinstalled, then mark the direction of rotation with a marker. If a new belt is to be installed, the toothed belt tensioner and tension roller must also be replaced (see illustration).

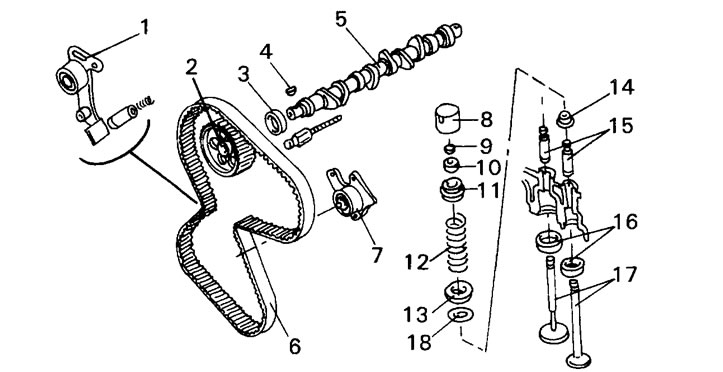

24.13 XUD9 engine timing parts

1 - toothed belt tensioner

2 - camshaft timing belt gear

3 - camshaft seal

4 - key

5 - camshaft

6 - toothed belt

7 - toothed belt tension roller

8 - poppet pusher

9 - valve clearance adjusting washer

10 - valve cracker

11 - valve spring plate

12 - valve spring

13 - valve spring support washer

14 - oil scraper cap

15 - valve guide

16 - valve seat ring

17 - valves

18 - gasket washer

All other parts are replaced with new ones depending on the need.

14. Make sure that there is no oil or grease on the parts in contact with the toothed belt. The thrust bolts must be located in the holes of the gears of the camshaft and injection pump. If during the work these bolts were removed, then the camshaft must be rotated so that the M8 bolt can be inserted into hole 7 (see illustration).

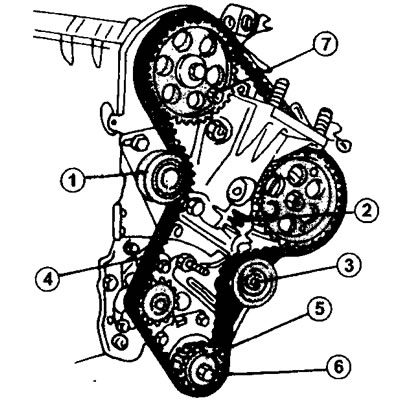

24.14 Installing the toothed belt on a 1.9 liter engine.

1 - tension roller

2 - toothed belt tensioner spring pusher

3 - guide roller

4 - toothed belt

5 - timing gear of the toothed belt on the crankshaft

6 - gear bolt

7 - thrust bolt in the hole of the camshaft gear

In this gear position, a toothed belt can be applied.

15. Loosen bolt 1 and nut 2 (see illustration 24.11) toothed belt tensioner so that the tension roller moves back to its original position. Make sure that the tension roller is in the correct position and tighten bolt 1 and nut 2.

16. Insert the thrust bolt into the appropriate hole on the injection pump gear. This position of the injection pump corresponds to the moment of fuel injection into the chamber of cylinder No. 1.

17. Fix the crankshaft in the TDC position by inserting the thrust rod into the hole on the flywheel as shown in illustrations 17.77.

18. Establish a gear belt. It is first placed on the crankshaft gear, then on the guide roller and on the injection pump gear, and then on the camshaft gear. Keeping tension on the toothed belt, secure it to the water pump gear and tension roller.

19. Make sure the belt teeth are properly in contact with the gears.

20. Install the timing belt gear bolt on the crankshaft with a washer on it and tighten the bolt.

21. Loosen bolt 1 and nut 2 (see illustration 24.11), to release the tensioner pulley.

22. Remove all bolts securing the shafts, as well as the flywheel blocking rod.

23. Rotate the crankshaft at least two turns in the direction of engine rotation to align the toothed belt.

Again loosen bolt 1 and nut 2 of the toothed belt tensioner (see illustration 24.11). In this case, the tension roller is set to the belt tension position. After that, tighten the bolt and nut with a torque of 18 Nm.

24. Turn the engine a few turns and reinsert the timing gear lock bolts. If the bolts are difficult to insert, this means that the valve timing is out of order and all work must be done again.

25. Turn out a bolt with a washer by which the gear wheel of a gear wheel on a cranked shaft is fixed.

26. Establish three parts of a protective casing of a gear belt.

27. Install the belt pulley on the crankshaft and screw in the bolt with the washer. Lubricate the thread of the bolt with a protective agent «Loctite». While holding the crankshaft from turning, tighten the belt pulley bolt to 40 Nm. From this position, turn the bolt another 60°.

All other work is carried out in the reverse order of removal.

28. Tighten bolt 1 and nut 2 of the toothed belt tensioner (see illustration) with a torque of 20 Nm.

24.28 Tighten bolt 1 and nut 2 of the toothed belt tensioner (see illustration) with torque 20 Nm

29. Install the engine mount and flywheel and clutch guards.

2.1 liter engine

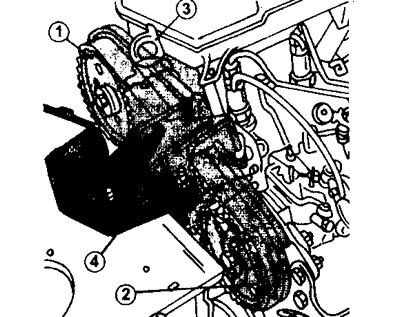

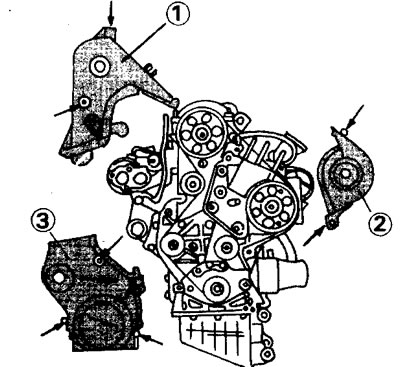

To remove the toothed belt on this type of engine, it is necessary to perform all work, including the removal of the toothed belt guard, in the same sequence as indicated for the 1.9 liter engine (see illustration 24.0a).

24.0a Remove the three-piece toothed belt guard (1-3), by unscrewing the mounting bolts marked with arrows. 2.1 liter engine

30. Attach a cable or chain to the engine and lift the engine with a hoist or equivalent. You can also install a garage lift under the engine with blocks of wood on top of it and carefully lift the engine up to relieve the mounts.

31. Remove the right engine mount.

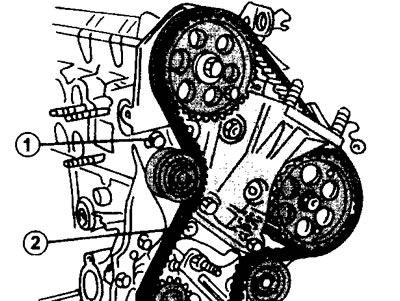

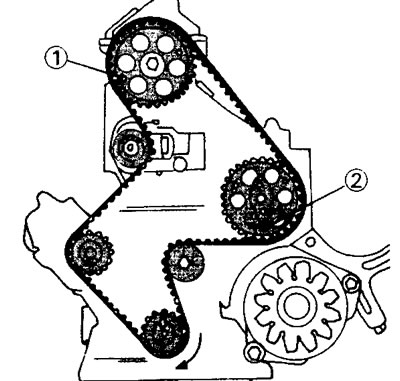

32. Prepare two bolts M8x1.25 and 40 mm long. Insert one bolt into the camshaft gear at point 1, and the second into the high pressure fuel pump drive gear at point 2 (see illustration).

24.32 Secure the camshaft gear 1 and gear 2 of the injection pump drive with stop bolts from turning

Thus, the gas distribution mechanism is blocked.

33. Remove the protective casing from the flywheel and clutch, and lock the flywheel accordingly or turn on the gear.

34. Turn out a bolt of fastening of a belt pulley on a cranked shaft and remove a pulley by means of two mounts or a puller.

35. Loosen the toothed belt tension. To do this, unscrew the nut 1 of the tension roller, as well as the bolt 2, using a 5 mm socket wrench (see illustration).

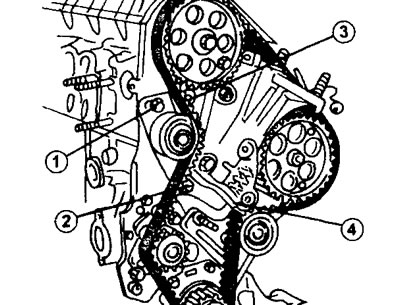

24.35 Removing and installing a toothed belt on a 2.1 liter engine.

1 - tension roller nut

2 - tensioner bolt

3 - socket wrench 5 mm

4 - tensioner eccentric

36. Use a 10 mm socket wrench and turn the eccentric 4 with it (see illustration 24.35) to the right to loosen the belt tension and remove it. If this toothed belt is to be reinstalled, then mark the direction of rotation with a marker. If a new belt is to be installed, the toothed belt tensioner and tension roller must also be replaced. All other parts are replaced with new ones depending on the need.

37. Make sure that there is no oil or grease on the parts in contact with the timing belt.

If the timing gear was removed from the crankshaft, then it must be reinstalled. Be careful not to move the key that secures the gear.

The thrust bolts must be located in the holes of the gears of the camshaft and injection pump. If during the work these bolts were removed, then the camshaft must be rotated so that the M8 bolts can be inserted into holes 1 and 2 (see illustration 24.32).

38. Install the toothed belt. If the old belt is installed, then be guided by the label of the direction of rotation of the belt. It is first placed on the injection pump gear, then on the guide roller, on the gears of the crankshaft and water pump, and then on the camshaft gear and tension roller.

39. Make sure the belt teeth are properly in contact with the gears.

40. Remove all bolts securing the shafts, as well as the flywheel lock rod.

41. Loosen nut 1 (see illustration 24.35), so that the tensioner pulley moves to the belt and tensions it.

42. Rotate the crankshaft at least two turns in the direction of engine rotation to align the toothed belt. In this case, the tension roller is set to the belt tension position. After that, tighten the nut 1 of the tension roller with a torque of 10 Nm (see illustration 24.35).

43. Turn the engine several times and re-insert the timing gear lock bolts. If the bolts are difficult to insert, this means that the valve timing is out of order and all work must be done again.

44. Install the three parts of the toothed belt guard.

45. Install the belt pulley on the crankshaft and screw in the bolt with the washer. Lubricate the thread of the bolt with a protective agent «Loctite». While holding the crankshaft from turning, tighten the belt pulley bolt to 40 Nm. From this position, turn the bolt another 60°.

All other work is carried out in the reverse order of removal. Don't forget to reinstall the flywheel and clutch disc guard.