The electronic control unit for ignition and fuel injection systems contains the so-called parametric characteristics obtained during bench tests. In addition, the ignition control unit receives information from the following system components:

- flywheel sensor. These are signals about the number of revolutions of the engine and the position of the crankshaft.

- coolant and intake air temperature sensors.

- throttle angle potentiometer. Information from this potentiometer is received both at the time of starting the engine and when the engine is idling.

Based on the information received from these sensors, the electronic control unit calculates the ignition timing, sets the charging time of the ignition coil in accordance with the engine speed, determines the battery voltage and the voltage on both coil windings.

Changing the ignition timing is performed by the control unit based on the parametric characteristics stored in its memory. In case the engine is operated under extreme conditions, the ignition timing can be adjusted in the workshop, bringing it into line with these operating conditions by resetting (removal) embedded characteristics. This adjustment protects the engine from potential engine damage caused by fuel knocking caused by fueling with low octane or poor quality gasoline. If such a situation can be predicted in advance, for example, when going to a country where the quality of fuel leaves much to be desired, then it is recommended to contact the workshop to make appropriate adjustments to the memory of the ignition control unit.

The ignition timing is adjusted in steps of 2°. The maximum ignition timing offset is 8°. To perform this adjustment, instrumentation is required, which is available only in workshops.

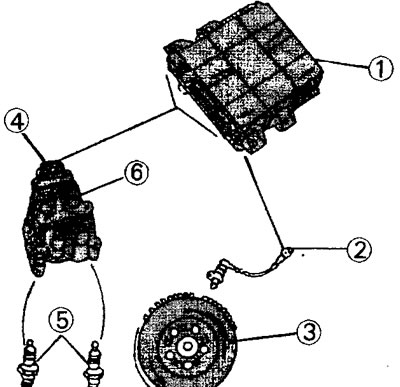

The elements of the ignition system are shown in illustration 2.0.

2.0 Elements of the ignition system.

1 - electronic control unit

2 - engine speed sensor

3 - flywheel with two missing teeth to determine the position of the crankshaft

4 - ignition coil

5 - spark plugs

6 - the second output stage of the ignition coil

The two spark plugs not shown in this illustration are connected to the second output stage of the ignition coil. The diagram shown is typical, but some engines may have different spark plug positions.

To remove the ignition coil, disconnect the battery and disconnect the plug. After that, it is necessary to disconnect the high voltage wires from the spark plugs and unscrew the four bolts securing the ignition coil. The procedure for installing the coil in place is the opposite of removing it.

Ignition advance angle

The ignition timing cannot be corrected. Checking and entering basic parametric characteristics is only possible with the use of instrumentation and must be carried out by the workshop.

Defective parts of the ignition system can cause engine malfunctions. If the engine is running poorly, then the cause may be a malfunction of the engine speed and crankshaft position sensor, ignition coil or control unit.

If the engine does not run at all, but the main functions of the ignition system are in order, then the failure of the automatic ignition timing may be the cause of engine failure. Such a failure can only be detected and corrected by a workshop, because in this case, instrumentation is needed, with the help of which a corresponding diagram is drawn up, which allows you to quickly detect an error in the settings.