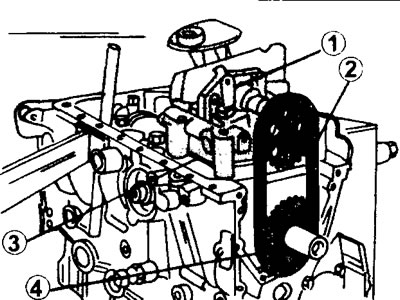

26.0 Location of the oil pump in the crankcase.

1 - oil pump

2 - drive chain

3 - spacer plate (if installed)

4 - oil pump drive sprocket on the crankshaft

The oil pump can be removed without removing the engine from the vehicle. The procedure for this is almost the same for all types of engines.

1. Put the front of the car on the gantry. If possible, raise the vehicle on a lift or place the front wheels of the vehicle on a ramp.

2. Remove the engine mudguard.

3. Place a suitable container under the crankcase and drain the oil from the sump. The flow oil should be slightly warm.

4. Turn out bolts of fastening of the oil pallet to a crankcase and disconnect the pallet. If the pallet is tight «is sitting» on the crankcase, then tap it with a rubber mallet, and then wring it out by inserting a screwdriver between the mating surfaces.

5. Remove the oil pump, proceeding as when disassembling the engine 9 see the relevant chapter).

The pump will need to be rotated a little to remove the drive chain. If the pump is removed due to the fact that it does not provide the necessary oil pressure for its circulation, then the pump should be returned for repair. A simple overhaul of the pump does not fix this problem. Separately, only the oil intake strainer can be replaced (see illustration).

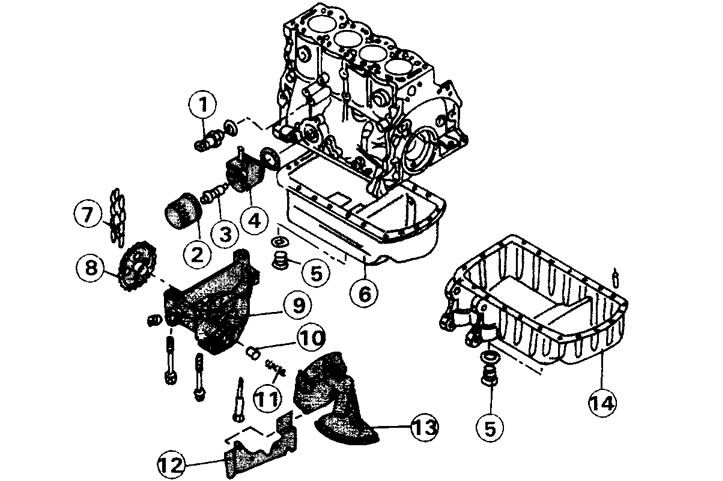

26.5 1.9 liter XUD diesel oil pan and oil pump

1 - oil pressure sensor with sealing ring

2 - oil filter

3 - a bolt of fastening of the case of the oil filter

4 - oil cooler (diesel engines)

5 - threaded drain plug with sealing ring

6 - oil pan made of sheet iron (cars without air conditioning)

7 - oil pump drive chain

8 - drive sprocket

9 - oil pump

10 - pressure reducing valve piston

11 - pressure reducing valve spring

12 - oil deflector

13 - mesh filter of the oil intake

14 - aluminum oil pan (cars with air conditioning)

If a defect in the pressure reducing valve is suspected, the valve can be unscrewed and its parts replaced. However, this requires the pump to be disassembled.

Before installing the pump, thoroughly clean the contact surfaces of the crankcase housing. The use of sharp or abrasive tools is not allowed.

6. Reinstall the oil pump. The drive chain must be put on the sprockets. In order to put the chain on the driven sprocket, tilt the front of the pump a little, and then put the pump on the mounting pin.

7. Install the oil pan and secure it with bolts. Do not forget that the pallet mounting bolts have different lengths.

8. Make sure the drain holes are closed with screw plugs. The tightening torque for the screw plugs is 25-30 Nm.

9. Fill with engine oil of the correct grade and volume as specified in the specification.

To avoid jamming of the oil pump when starting the engine after removing and installing the pump, it is recommended to disconnect the plug of the fuel cut-off valve power wire on the injection pump or the spark plug high voltage wire and crank the engine for about 30 seconds. using a starter. After that, connect the wires or plug and start the engine, letting it idle for a while.

10. Make sure there is no oil leaking from the sump anywhere. After a while, check the engine oil level and top up if necessary to bring it up to the correct level.