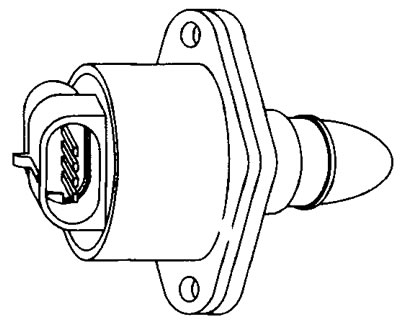

12.19 Idle stepper motor (ISSM)

The bypass channel relative to the throttle valve is located in the throttle body. The valve is located in the channel. When the valve is moved, air passes through the passage and this affects the idle speed. Then the idle speed depends on the position of the stepper motor pneumatic valve located in the bypass channel.

The electronic control unit controls the stepper motor via two motor windings. Each pulse from the electronic control unit causes the stepper motor to rotate in steps (those. 1/1 turn or 0.04 mm).

When additional power consumers are switched on, for example: headlights or a heater fan, the idling speed will decrease. In this case, the ECM will open the stepper motor valve to maintain the previous idle speed.

When the engine is turned off, power is supplied to the stepper motor for 4-5 seconds, thus the electronic control unit closes the air valve (preventing spontaneous engine start). After a few seconds, the electronic control unit activates the air valve, which opens slightly, and the engine is ready for the next start.

If the engine speed exceeds idle speed, then the stepper motor will place the air valve in a position where the air supply is completely cut off. When braking, the stepper motor will open the bypass, allowing additional air to enter the intake manifold. This helps to reduce excessive emissions of harmful substances into the atmosphere during braking.

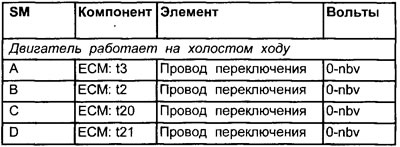

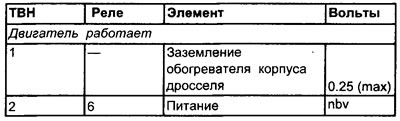

Idle Stepper Motor Voltage Values (SM)

Terminal numbers

See illustration 12.2

Idle Stepper Motor Resistance Values

Terminal numbers

Idle air control valve type

Stepper motor.

Influence of external factors

- Basic throttle setting

- Vacuum leak

- Throttle sticking

- Poorly adjusted or stuck throttle cable

Checking the stepper motor (general check)

1. Inspect the multi-pin stepper motor connector for signs of corrosion or damage.

2. Verify that the connector terminal pins are properly installed and making good contact with the multi-pin idler stepper motor connector.

Low idle

1. Let the engine run at idle speed.

2. Make sure the idle speed is within specification.

3. Increase the load on the engine by turning on the headlights, rear defroster and heater fan. The idle speed should change.

4. If no deviations were found during the check, then most likely the state of the stepper motor will also be normal.

Stepper motor checks

1. Remove the stepper motor from the intake manifold.

2. Make sure the air passage is clean. Clean the channel if necessary.

3. Check that the shaft and cone rotate freely in the motor armature.

4. Install the stepper motor.

5. Disconnect the multi-pin connector of the stepper motor or electronic control unit.

6. Measure the resistance of the motor windings at terminals A and D and at terminals B and C.

7. Compare your results with the values given in the specifications.

8. Connect all multi-pin connectors.

9. Connect the negative lead of an oscilloscope or voltmeter to ground on the motor.

10. Connect the positive lead of an oscilloscope or voltmeter to terminal #A of the stepper motor signal wire.

11. Let the engine run at idle speed.

12. Switch components on and off, for example: rear defroster, high beam headlights and heater fan. Set the rear window heater and heater fan to the maximum mode. The voltage should switch from zero to battery voltage as the motor winding supplies power.

13. Repeat the checks on terminals #B, #C, and #D of the stepper motor signal wire.

14. If there is no signal, check the continuity of the electrical wiring going between the multi-pin connector of the electronic control unit and the stepper motor.

15. If the wiring of the stepper motor is normal, then check the power and ground contacts of the electronic control unit. If the contacts are in order, then the electronic control unit may be faulty.

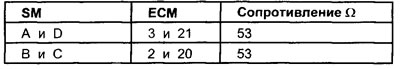

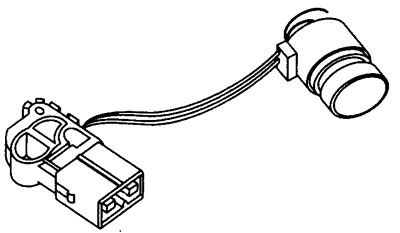

Intake manifold heater (IMH)

intake manifold heater (IMH) (see illustration 12.20) designed to heat the throttle body so that it does not freeze in cold weather. When the engine is running, the heater is on all the time. Heater, PTC (RTS) allows the current to quickly heat the inductor body during the warm-up process. As the heater heats up, the resistance increases and the current decreases.

12.20 Intake manifold heater (IMH)

Intake manifold heater voltage values (TVN)

Terminal numbers

See illustration 12.2

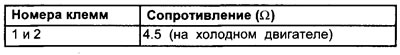

Intake manifold heater resistance (TVN)

Intake manifold heater type

Positive temperature coefficient (RTS)

Express test

- Start the engine from a cold state and touch the area around the throttle body. If the heater is running, this area should become very hot in a very short time. Be careful not to burn your fingers!

Intake manifold heater checks

1. Let the engine run at idle speed.

2. Connect the negative lead of the voltmeter to ground.

3. Connect the positive voltmeter lead to the heater power connector.

4. The voltmeter should show the nominal voltage of the battery.

5. Lack of supply voltage.

6. Check the output voltage from the relay.

7. Check up presence of conductivity of wires between the relay and a heater.

8. If battery voltage is present but the heater is not using it.

9. Check heater resistance.

10. Check heater grounding.