11.23 Knock sensor (KS)

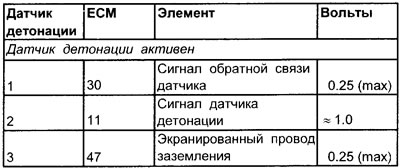

Knock sensor voltage values (KS)

Terminal numbers

See illustration 11.24

11.24 Wiring diagram for knock sensor KS

Note. The knock sensor signal will provide a maximum voltage amplitude of approximately 1.0 volts.

Knock sensor frequency

Approximately 15 kHz.

Influence of external factors

- Incorrect setting of the main ignition timing

- Low quality gasoline

- Ignition system malfunction

- Cooling system failure

- The formation of deposits in the cylinders

Checking the knock sensor (general check)

1. Inspect the knock sensor multi-pin connector for signs of corrosion or damage.

2. Make sure the connector terminal pins are properly installed and making good contact with the knock sensor multi-pin connector.

Knock sensor test procedure

Note. If the engine does not have timing marks, then the No. 1 cylinder piston must be set to TDC and appropriately marked on the housing and front pulley in order to perform the following procedure.

1. Connect the inductive strobe probe to the high voltage wire of cylinder #1.

2. Let the engine run at idle speed.

3. Gently tap the engine block around cylinder #1.

4. The ignition timing should be noticeably delayed.

5. Move the probe of the inductive stroboscope to cylinder no. 4.

6. Gently tap the engine block around cylinder #4.

7. The ignition timing should be noticeably delayed.

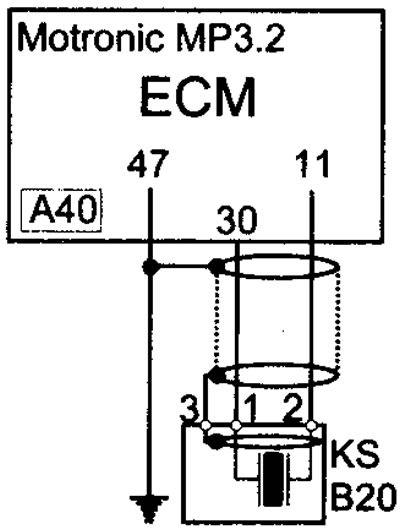

Knock sensor test procedure (Oscilloscope)

1. Connect the low voltage probe of the oscilloscope to the No. 2 terminal of the knock sensor signal wire.

2. Gently tap on the engine block near one of the cylinders.

3. The oscilloscope should reflect the waveform of the knock sensor signal (see illustration 11.25)

11.25 Typical KS knock sensor output waveform

4. Repeat procedure for other cylinders.