XU10 engines

1. Drain the engine oil.

2. Disconnect all the details fixed on a head of the block of cylinders.

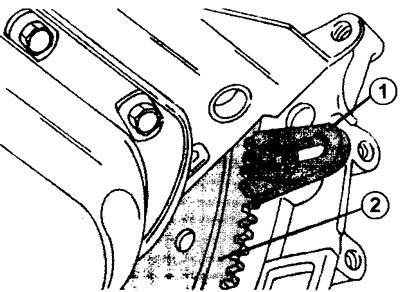

3. Secure the flywheel from turning. To do this, install the appropriate shoe on the flywheel ring gear or insert a large screwdriver (see illustration).

4.3 Handwheel 2 is secured against turning with a suitable «brake shoe» 1, mounted on the ring gear

4. Turn away on the inside of a belt pulley of a cranked shaft a bolt of fastening with a laying.

5. Remove the belt pulley from the shaft. Use mounts if necessary.

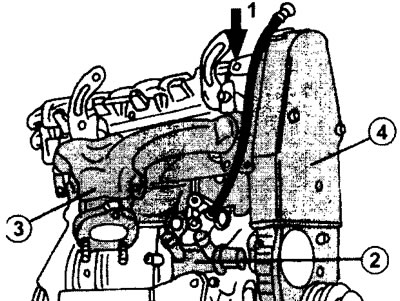

6. Remove the two-piece toothed belt guard, oil level gauge guide tube (probe), coolant inlet and exhaust manifold (see illustration)

4.6 Remove the two-part protective casing 4 of the toothed belt, the guide tube 1 of the oil level indicator (probe), coolant inlet 2 and exhaust manifold 3

7. Disconnect the oil filter using the filter wrench. If there is none, pierce the oil filter with a screwdriver and disconnect it by turning the screwdriver. The oil filter must be replaced in any case, so damage to it during removal does not matter.

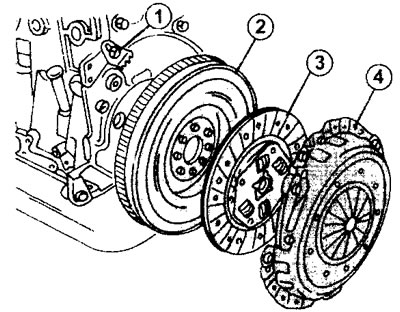

8. Turn away bolts of fastening on a flywheel of a pressure plate of coupling in a cross order. Before dismantling the pressure plate, mark the position of the pressure plate and flywheel relative to each other so that they can be installed in the same way during assembly (see illustration).

4.8 Removing the clutch pressure plate

1 - «brake shoe» flywheel

2 - flywheel

3 - clutch disc

4 - clutch pressure plate

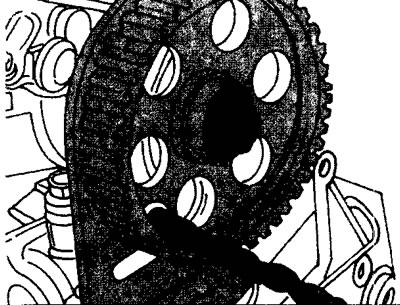

9. Turn out the central bolt of a gear wheel of a camshaft, holding it from turning. To keep the gear from turning, you can use a drill of the appropriate diameter (see illustration).

4.9 To keep the gear from turning, you can use a drill of the appropriate diameter

The position of the crankshaft and camshafts in this case does not matter, because the gas distribution mechanism will still need to be adjusted when assembling the engine.

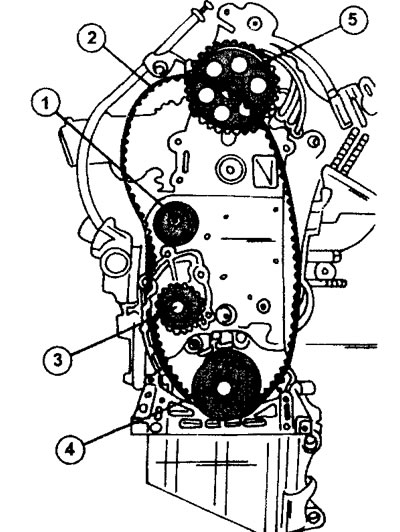

10. Remove the toothed belt from the gears and tension roller. To do this, loosen the position of the belt tensioner, move the tensioner to the side and remove the toothed belt from the gears (see illustration).

4.10 Removing the toothed belt. XSHO engine

1 - tension roller

2 - toothed belt

3 - water pump gear

4 - crankshaft timing gear

5 - camshaft drive gear

11. Designate a paint or a felt-tip pen the direction of rotation of a gear belt. It matches the direction of rotation of the motor. This mark will be needed if the old toothed belt is installed.

Attention! Keep the toothed belt free of oil or grease and avoid bending the belt. It is recommended to hang the removed toothed belt on a hook or nail.

The camshaft drive gear does not need to be removed.

12. Disconnect high voltage spark plug wires.

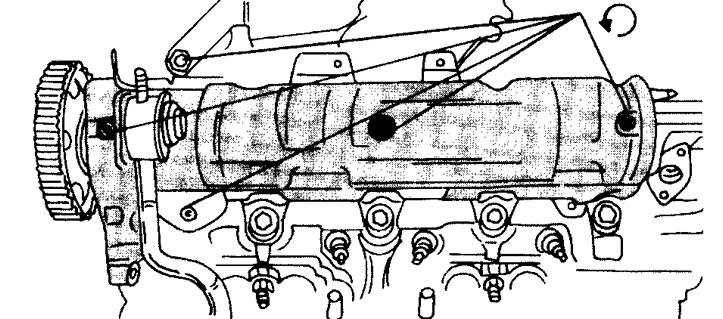

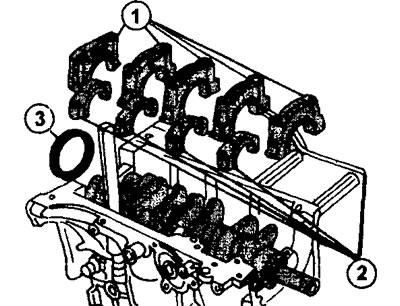

13. Turn out bolts of fastening and remove a cover of a head of the block of cylinders. For engines with 16 valves (two camshafts) the cylinder head cover bolts are turned out in several passes, acting from the center outward. For engines with 8 valves, the cylinder head cover is attached as shown in (illustrations 4.13).

4.13 Fastening the cylinder head cover of an 8-valve engine

14. Disconnect and remove the generator along with the mounting console, oil pressure regulator and engine mount brackets.

15. Turn away eight bolts of fastening of a flywheel in a cross order and bring down a flywheel a rubber hammer. Be careful not to drop the flywheel. Above the flywheel is a small plate that can also be removed. At the same time, access to the oil hole screw plug will be released. Remove the plug with a socket wrench.

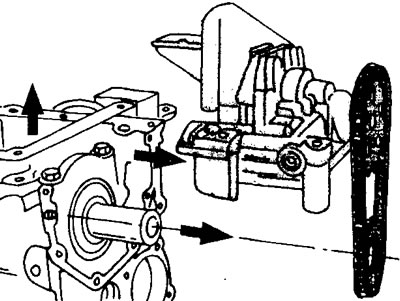

16. Remove the crankshaft timing gear. Behind the gear are the toothed belt insert and guide, which are removed with the gear. Next to the water pump drive gear is a second oil drain hole, closed with a screw plug. Unscrew this plug with a socket wrench.

17. Remove the cover on the end side of the engine, secured with six bolts. Knock out the seal in the cover (see illustration).

4.17 Remove the cover on the end side of the motor

18. Turn out a bolt of fastening of a roller of a tension of a gear belt and remove a roller. The support bolt can also be unscrewed.

19. Turn out bolts of fastening of the water pump access to which became possible after removal of a cover from the face side of the engine. At the same time, remove the adjacent coolant pipe and gasket by unscrewing the three mounting bolts.

20. Remove the remaining engine mount brackets.

21. Turn out bolts of fastening and remove a head of the block of cylinders (see relevant chapter). After removing the cylinder head, write down the corresponding cylinder numbers on the top side of the pistons.

22. Turn the engine over with the crankcase up and remove the crankcase. The crankcase for this type of engine can be installed with or without a gasket.

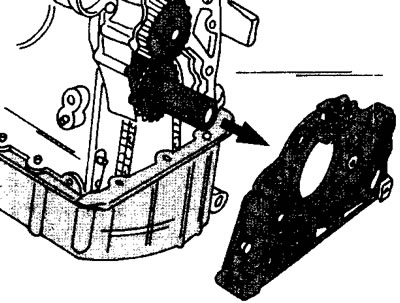

23. Turn out on the bottom party of the block of cylinders three bolts of fastening of the oil pump and remove the oil pump. In order to remove the oil pump, it must first be lifted and then pushed forward. The pump drive gear is removed along with the chain. Usually a gasket is installed between the oil pump and the cylinder block (see illustration).

4.23 In order to remove the oil pump, it must first be lifted up and then pushed forward (see arrows)

24. Turn away in order nuts of bolts of fastening of covers of conrod bearings and remove covers. To remove the connecting rod bearings, it is necessary to rotate the crankshaft so that the corresponding bearings, two by two, go to bottom dead center. Remove the liners from the connecting rod journals and install them in the corresponding caps. Connecting rods and connecting rod caps have a mark on one side.

25. Knock out the pistons together with the connecting rods from the piston holes. Before doing this, make sure that the pistons are marked according to the cylinder numbering. After removing the piston and connecting rod, attach the connecting rod cap and bearing to the connecting rod.

26. Apply marks on the main bearing caps and on the cylinder block with a core.

27. Loosen the bolts, working from the outside towards the middle, and remove the covers together with the bottom bushings. When removing the second cover, remove the two thrust half rings (see illustration).

4.27 Remove caps 1 of main bearings, caps of 2 connecting rods and oil seal on the rear end of the crankshaft

When purchasing main bearing shells, be sure to indicate the year of manufacture, engine number, because the shells may differ.

28. Remove the crankshaft and upper main bearing shells and the two remaining thrust washers.

29. Assemble the liners and caps together. The oil seal on the rear end of the crankshaft can be removed after removing the shaft from the cylinder block (see illustration 4.27).

1.8 liter XU7 engines

The disassembly of this engine up to the removal of the cylinder head is carried out identically.

30. Remove the cylinder head (see relevant chapter).

31. Mark the pistons and cylinder liners with a marker.

32. Turn away nuts of bolts of covers of rods and remove covers, and also sleeves of cylinders together with pistons and rods and lay them accordingly. Remove the pistons from the cylinder liners.

33. Remove the main bearing caps with the lower shells, having previously marked the mounting position of the caps on the cylinder block.

34. Remove the crankshaft and remove the upper halves of the liners from the beds.