Attention! Before disassembling the front suspension strut, you should purchase an appropriate tool to hold the spring in a compressed state. Adjustable spring compressors are available and recommended for this procedure (spring pullers), providing rigid fixation relative to the spring. Any attempt to disassemble the strut without this tool could result in vehicle damage or personal injury.

1. After removing the rack from the car, clean it from adhering dirt. Clamp the rack in a vise in a vertical position.

2. Install the pullers on the spring (if you haven't already). Use pullers that can be fixed firmly on the spring (usually with a small clamping bolt). Any other type of tool may slip or slide off the spring as it is tightened. Tighten the pullers enough to remove the load from the spring plate.

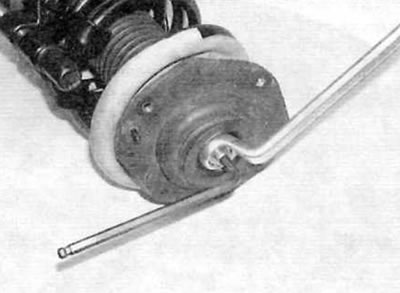

3. Remove the protective cover, then unscrew the piston rod nut while holding the piston rod with a suitable internal hex wrench (pic. 5.3). Keep in mind that assembly will require a new nut.

Pic. 5.3. Loosen the strut piston rod nut while holding the piston rod with a suitable socket wrench

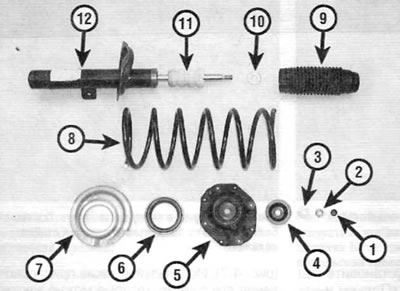

4. Loosen the nut, remove the washer, then remove the spacer ring, base plate, bearing, top spring cup and flat washer. Remove the coil spring, then remove the piston dust cover and dynamic sag rubber (pic. 5.4). The spring can be left in a compressed state, ready to be installed on the suspension strut. If you are going to install a new spring, carefully remove the pullers from «old» springs.

Pic. 5.4. Elements of the front suspension strut

1. Protective cap

2. Piston rod nut

3. Washer

4. Ring

5. Base plate

6. Bearing

7. Upper spring plate

8. Coil spring

9. Piston dust cover

10. Flat washer

11. Dynamic deflection limiter

12. Stand body

5. Now that the rack is completely disassembled, inspect all components for wear, damage, and deformation, and check for smooth bearing operation. Replace required items.

6. Inspect the rack body for signs of fluid leakage or damage. Check the strut piston along its entire length for signs of pitting. Check rack operation. While holding the shock absorber in a vertical position, check its operation by moving the rod to the full stroke and then making short strokes of 50-100 mm. In both cases, the resistance should feel smooth and constant. If you feel uneven resistance or jerking, or there are visible signs of wear or damage to the shock absorber, it is necessary to replace it.

7. If there is any doubt about the condition of the spring, carefully remove the spring pullers and inspect the spring for deformation and signs of cracking. Replace the spring if it is damaged or deformed.

8. Follow the accompanying photos to assemble the suspension strut. Follow the prescribed sequence and strictly follow the captions under the figures (pic. 5.8, a-l).

Pic. 5.8, a. Extend the piston rod as far as possible and install the dynamic sag limiter

5.8b. Install the piston dust cover...

5.8, c....compressed spring...

Pic. 5.8, d.... making sure that the end of the lower coil is correctly located on the lower plate

5.8, e. Install the flat washer...

Pic. 5.8, e.... the upper spring plate...

Pic. 5.8, f....bearing...

Pic. 5.8, s....and base plate

Pic. 5.8, and. Install the distance ring on the base plate...

Pic. 5.8, to.... install the top washer...

Pic. 5.8, l....then screw and tighten the piston rod nut

9. Upon completion of assembly, install the suspension strut on the vehicle as described in paragraph 4.