Note. Peugeot/Citroen prescribes the use of a special electronic tool (SEEM C.TRONIC belt tension measuring tool, type 105) for correct tension adjustment of an accessory drive belt equipped with a manually adjustable tensioner. This procedure varies greatly depending on engine type, model year, and belt type and condition. The procedure described below is an alternative method that does not require the use of electronic equipment. If any problems occur (e.g. screeching at startup) have the tension checked by a dealer using a special electronic tool at the earliest opportunity.

1. Depending on the specification, the vehicle is equipped with one or two accessory drive belts. If two belts are installed, the outer belt will need to be removed to replace the inner belt.

Examination

2. Place wheel chocks under the rear wheels. Raise the front of the vehicle and securely jack stands under it (see «Lifting and placing the car on supports»). Remove the right front wheel.

3. From under the front of the car, unscrew the screws, remove the clips and remove the wheel arch locker to gain access to the crankshaft sprocket/pulley bolt. If necessary, release the coolant hoses from the clips on the fender for easier access later.

4. Using a suitable socket and extension, slowly rotate the crankshaft at the crankshaft sprocket/pulley bolt while inspecting the entire length of the drive belt. Check the drive belt (belts) for cracks, cuts, abrasions and other damage. Also check the belt for signs of «brining», which gives the belt shine, and signs of delamination. If the belt is worn or damaged, replace it.

5. If the condition of the belt is satisfactory, on models where the belt is adjusted manually, check its tension as described below, taking into account the note given at the beginning of this paragraph. On models with an automatic spring tensioner, there is no need to check the drive belt tension.

Manual regulator on the bottom support of the generator

Removing

6. Follow the steps in steps 2 and 3 if you have not already done so.

7. Disconnect the wire «masses» from battery (see «Disconnecting the battery» in the application).

8. Loosen the top and bottom alternator mounting bolts and, if applicable, the adjusting bar mounting bolt (pic. 10.8, a, b).

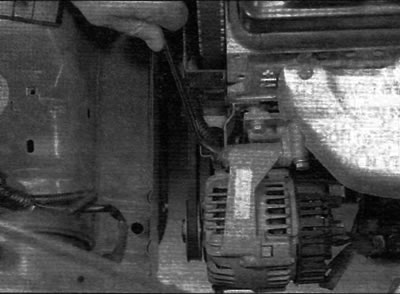

Pic. 10.8, a. Loosen the top alternator mounting bolt...

9. If necessary, turn the adjusting bolt to relieve tension on the drive belt, and then remove the belt from the pulleys (pic. 10.9, a, 6).

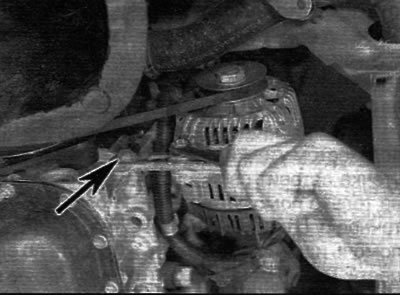

Pic. 10.8, b....lower bolt and adjustment bar (marked with an arrow) (models with a manual regulator on the bottom support of the generator)

Note. If the belt is to be reused, mark the direction of rotation on the belt before removing it. This will ensure that the belt is installed correctly.

Installation

10. When replacing a belt, make sure that the new belt is of the correct type, and if a removed belt is being installed, follow the marks made during removal to install it correctly. Slide the belt over the pulleys and use the adjusting bolt to take up the slack in the belt.

11. Tension the drive belt as described in the following paragraphs.

Stretching

12. Follow the steps in steps 2 and 3 if you have not already done so.

13. The belt should be tensioned so that there is approximately 5.0 mm deflection in the middle of the longest section between the pulleys when applying strong thumb pressure (see note at the beginning of this paragraph).

Advice. Proper tension on the drive belt ensures reliable operation for the entire life of the drive belt, and slack causes slippage and squealing. Beware of exceeding the required tension, as this may contribute to increased wear on the generator bearings.

14. To make the adjustment, turn the adjusting bolt just enough to give the correct tension. This should be done in a position where the mounting bolts are holding the alternator, but still allowing for a slight amount of movement.

15. Turn the crankshaft two turns, check the tension again, and then tighten both generator supports. If applicable, also tighten the adjustment bar bolt to the appropriate support bracket.

16. Connect the wire «masses» to the battery.

17. Fix the coolant hoses in their original position (where necessary) and install the wheel arch locker. Install the wheel and lower the car.

Mobile idler pulley with manual adjustment

Removing

18. Follow steps 2 and 3 if you have not already done so.

19. Disconnect the wire «masses» from battery (refer to paragraph «Disconnecting the battery»).

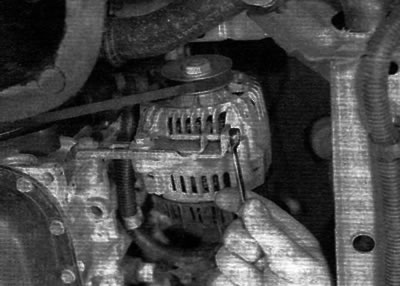

Pic. 10.9, a. Turn the adjusting bolt to take the tension off the drive belt...

Pic. 10.9, b....then remove the belt from the pulleys (models with a manual regulator on the bottom support of the generator)

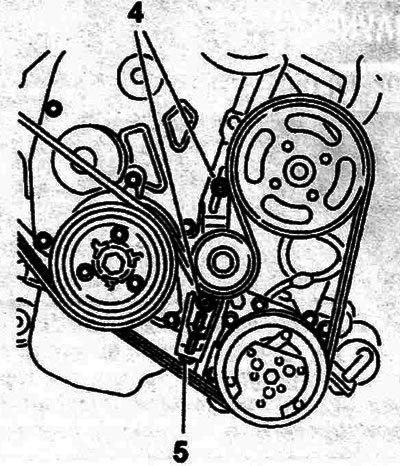

20. Loosen the two bolts securing the idler pulley assembly to the engine (pic. 10.20).

Pic. 10.20. Idler pulley mounting screws (4) and adjusting bolt (5) (models with movable idler pulley with manual adjustment)

21. Turn the idler bolt to move the idler pulley away from the drive belt until there is enough slack in the drive belt to remove the belt from the pulleys. Note. If the belt is to be used further, mark the direction of rotation on the belt before removing it. This will ensure that the belt is installed correctly.

Installation

22. When replacing a belt, make sure that the new belt is of the correct type, and if a removed belt is being installed, follow the marks made during removal to install it correctly. Slide the belt over the pulleys so that the ribs of the belt fit correctly into the grooves on the pulleys and the belt is routed properly. Take up the slack in the belt with the adjusting bolt of the idler pulley. Tension the belt as described below.

Stretching

23. Follow steps 2 and 3 if you have not already done so.

24. Proper drive belt tension will ensure a long service life.

25. The belt should be tensioned so that when pressed hard with the thumb, the deflection in the middle of the longest section between the pulleys is approximately 5.0 mm (see note at the beginning of this paragraph).

26. To adjust the tension, loosen the two idler pulley assembly mounting bolts and turn the adjusting bolt just enough to provide the correct tension. Once the belt is properly tensioned, rotate the crankshaft two turns and check the tension again.

27. After verifying that the belt tension is correct, securely tighten the idler pulley assembly mounting bolts, and then connect the wire «masses» to the battery.

28. Fix the coolant hoses and install the wheel arch locker. Install the wheel and lower the vehicle. Fixed idler pulley with manual adjustment.

Removing

29. Follow steps 2 and 3 if you haven't already.

30. Disconnect the wire «masses» from battery (refer to paragraph «Disconnecting the battery»).

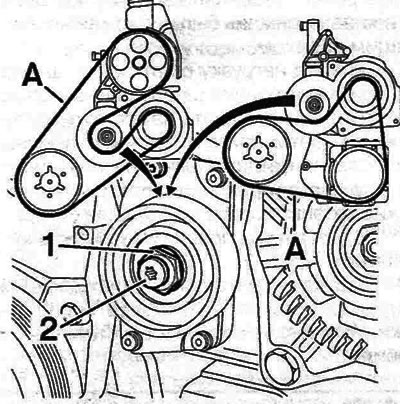

31. Loosen the idler pulley mounting nut and turn the center bolt to move the pulley away from the drive belt until there is enough slack in the drive belt to remove the belt from the pulleys (pic. 10.31). Note. If the belt is to be used further, mark the direction of rotation on the belt before removing it. This will ensure that the belt is installed correctly.

Pic. 10.31. Loosen the pulley nut (1) and turn the center bolt (2), to adjust the drive belt tension. The callout shows the belt tension test point (A) (fixed idler models with manual adjustment)

Installation

32. When replacing a belt, make sure that the new belt is of the correct type, and if a removed belt is being installed, follow the marks made during removal to install it correctly. Slide the belt over the pulleys so that the ribs of the belt fit correctly into the grooves on the pulleys and the belt is routed properly. Tension the belt as described below.

Stretching

33. Follow steps 2 and 3 if you haven't already.

34. Proper drive belt tension ensures long belt life (see «Haynes advises» higher).

35. The belt should be tensioned so that when pressed hard with the thumb, the deflection in the middle of the longest section between the pulleys is approximately 5.0 mm (see note at the beginning of this paragraph).

36. To adjust the tension, loosen the idler pulley mounting nut and turn the center bolt just enough to provide the correct tension. Once the belt is properly tensioned, hold the center bolt and tighten the pulley nut securely. Rotate the crankshaft two turns and check the tension again.

37. Fix the coolant hoses and install the wheel arch locker. Install the wheel and lower the car.

Spring-loaded idler pulley with automatic adjustment

Removing

38. Follow steps 2 and 3 if you haven't already done so.

39. Disconnect the wire «masses» from battery (refer to paragraph «Disconnecting the battery»).

40. If necessary, remove the screws from the power steering pump pulley shield and remove the shield to gain access to the top of the drive belt.

41. Take the pulley away from the drive belt with a wrench behind the pulley mounting nut. Turn the idler pulley counterclockwise to move away from the belt. Note. The idler pulley is left-hand threaded and therefore does not release when the tension is released from the belt.

42. After releasing the tension, to hold the pulley in the released position, insert a 4.0 mm Allen wrench into the hole in the base of the pulley assembly. Remove the belt from all pulleys, having previously noted the wiring diagram, and remove the belt from the engine. Note. If the belt is to be used further, mark the direction of rotation on the belt before removing it. This will ensure that the belt is installed correctly.

Installation and tension

43. When replacing a belt, make sure the new belt is of the correct type, and if a removed belt is being installed, follow the marks made during removal to install it correctly. Slide the belt over the pulleys so that the ribs of the belt fit correctly into the grooves on the pulleys and the belt is routed properly.

44. Remove the load from the idler pulley and remove the internal hex wrench. Release the pulley and allow the tensioner to automatically tension the belt.

45. Install the power steering pump pulley guard (if removed) and securely tighten the appropriate screws.

46. Connect the wire «masses» to the battery.

47. Fix the coolant hoses and install the wheel arch locker. Install the wheel and lower the car.