Engines 1.9 l

Examination

1. The importance of proper valve clearance adjustment cannot be overestimated, as they have a significant impact on the dynamic performance of the engine. However, the check should not be regarded as a planned operation. It should be done when the valve train makes noise, after an engine overhaul, or when trying to find the cause of a loss of power. The clearance check is performed as described below. To ensure the accuracy of the test, it should be performed on a cold engine.

2. Fully apply the parking brake. Raise the front of the vehicle and securely jack stands under it (see «Lifting and placing the car on supports»). To gain access to the right end of the engine, remove the plastic locker from the wheel arch. The locker is fixed in the wheel arch with various screws and clamps. Release all clamps and remove the locker from under the front fender. If necessary, release the coolant hoses from under the wing to facilitate further access.

3. The engine can now be turned using the appropriate socket and extension for the crankshaft pulley bolt. Keep in mind that the crankshaft should only be turned clockwise (when viewed from the right side of the car).

4. Remove the cylinder head cover as described in paragraph 4.

5. Take a piece of paper and draw the outline of the engine in plan, indicating the cylinders, which are numbered starting from the flywheel. Show the position of each valve and record the prescribed valve clearance. Above the position of each valve, draw lines to record the actual clearance (1) and the value of the necessary adjustment (2) (pic. 12.5).

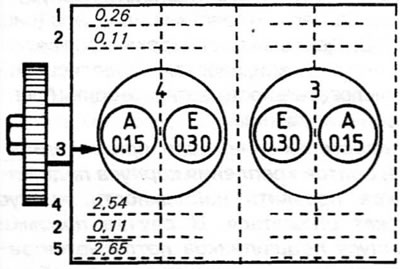

Pic. 12.5. Example of calculating the thickness of the shim (engines 1.9 l)

A intake valve

E Exhaust valve

1. Measured clearance

2. Difference compared to prescribed value (3)

3. Prescribed clearance

4. Thickness of installed shim

5. Thickness of required shim

6. Turn the crankshaft until the inlet valve of cylinder No. 1 (closest to the gearbox) was completely closed, that is, the tip of the cam was facing away from the pusher.

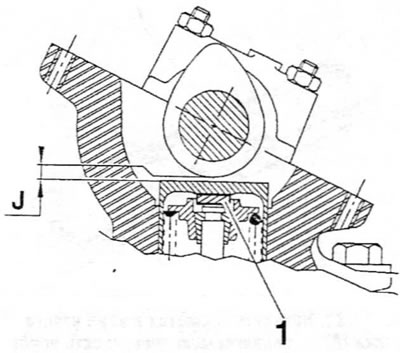

7. Using «fan» feeler gauge, measure clearance between cam base and tappet (pic. 12.7). Write down the gap value on the line (1).

Pic. 12.7. Valve clearance measurement (J). The clearance is adjusted by replacing the shim (1) (engines 1.9 l)

8. Repeat the measurements for the remaining seven valves, turning the crankshaft if necessary so that the corresponding cam always faces away from its paired pusher.

9. Calculate the difference between each measured gap and the required value and write the result on the line (2). Since intake and exhaust valve clearances are different, make sure you know which valve you are dealing with. Valve sequence when counting from either end of the engine:

Inlet - Outlet - Outlet - Inlet - Inlet - Outlet - Outlet - Inlet.

10. If all clearances are correct, install the cylinder head cover (see paragraph 4). Install the wheel arch locker. Lower the car. If any measured clearance is not correct, adjustment should be made as described in the following paragraphs.

Adjustment

11. Remove the camshaft as described in paragraph 11.

12. Remove the first pusher along with its shim. Clean the shim and measure its thickness with a micrometer. The shims have thickness markings, but wear can cause the original thickness to drop. So check the specified value.

13. Refer to the clearance values recorded for the valve in question. If the gap was greater than prescribed, the thickness of the shim should be increased by the difference recorded on the line (2). If the gap was less than prescribed, the thickness of the shim should be reduced by the difference recorded on the line (2).

14. Draw three more lines under the position of each valve on the control sheet as shown (pic. 12.5). On line (4) record the measured shim thickness and then add or subtract the difference shown on the line (2), to get the final thickness of the required shim, which should be written on the line (5).

15. Repeat the procedure according to paragraphs 12-14 on the remaining valves, maintaining the order of the location of all pushers.

16. Prepare the shims required to correct each valve clearance. Keep in mind that shims can be interchanged, but tappets cannot.

17. When assembling, lubricate the adjusting shim and install it on the valve disc so that the size marking is facing down. Lubricate the pusher and lower it onto the adjusting shim. Do not lift the tappet after installation as the shim may move.

18. When all the pushers, together with their shims, are in place, install the camshaft as described in paragraph 11. Before installing the cylinder head cover, check the valve clearances again to make sure they are correct.

Engines 2.0 l

19. The 2.0L engine is equipped with hydraulic tappets that automatically adjust valve clearances. Therefore, there is no need to check or adjust valve clearances.