Right cuff

1. Remove the crankshaft sprocket as described in paragraph 9.

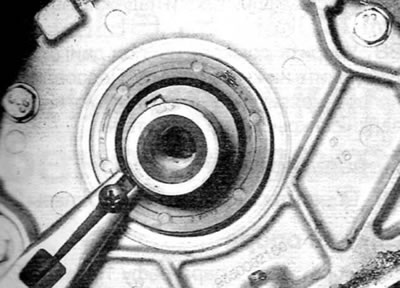

2. Mark the installation depth of the collar relative to the body surface to ensure correct installation. Punch or drill two diametrically opposite small holes in the cuff. Screw a self-tapping screw into each hole and, pulling the screws with pliers, remove the cuff (pic. 17.2). Alternatively, carefully pry out the cuff using a flathead screwdriver. Be extremely careful not to damage the collar on the crankshaft/oil pump drive gear or the seal housing.

Pic. 17.2. Using a self-tapping screw and pliers, remove the right crankshaft seal

3. Clean the cuff body and remove any burrs or burrs that could cause damage to the cuff when it stops.

4. Lubricate the sealing lips of the new oil seal with clean engine oil and carefully fit it onto the end of the crankshaft. Note that the sealing lip must face inwards. Be careful not to damage the sealing lips during installation.

5. Install the cuff to the depth indicated when removed. Use a suitable tubular mandrel, such as a socket, that only rests against the hard outer edge of the cuff. The inner surface of the cuff should be flush with the inner wall of the engine crankcase.

6. Wash off all traces of oil, and then install the crankshaft sprocket as described in paragraph 9.

Left cuff

7. Remove the flywheel (see paragraph 9).

8. Mark the installation depth of the cuff relative to the body surface to ensure correct installation, punch or drill two diametrically opposite small holes in the cuff. Screw a self-tapping screw into each rejected screw and, pulling the screws with pliers, remove the cuff.

9. Clean the cuff body and remove any burrs or burrs that could cause damage to the cuff when it stops.

10. Lubricate the sealing lips of a new cuff with clean engine oil and carefully fit it onto the end of the crankshaft.

11. Install the cuff to the depth marked when removed. Use a suitable tubular mandrel, such as a socket, that only rests against the hard outer edge of the cuff.

12. Wash off all traces of oil, and then install the flywheel as described in paragraph 19.