Removing

1. Remove the oil pan as described in paragraph 14.

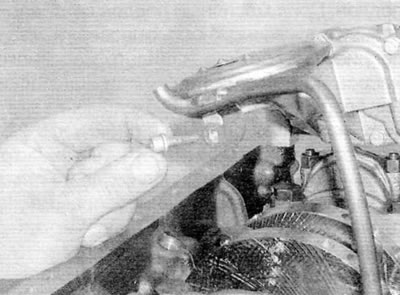

2. Remove the bolt that secures the dipstick guide tube to the oil pump and remove the tube from the cylinder block (pic. 15.2, a, b).

Pic. 15.2, a. Remove the bolt that secures the dipstick guide tube to the oil pump...

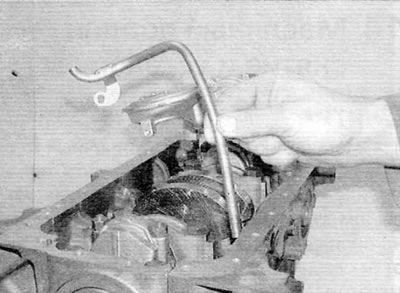

Pic. 15.2, b.... then remove the guide tube from the cylinder block (shown on removed engine)

3. On engines of 1.9 l release and turn out three bolts of fastening of the oil pump. Mark for yourself the installation position of the longer bolt. Disengage the pump sprocket from the chain and remove the oil pump and separator plate from the engine.

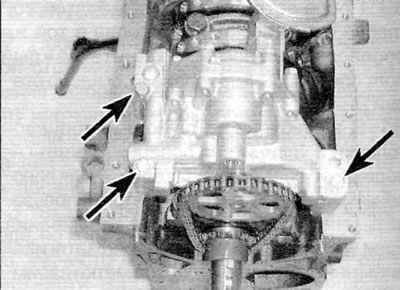

4. On engines of 2.0 l release and turn out three bolts of fastening of the oil pump. Mark for yourself the installation position of each bolt (they have different sizes) and sealing washer (pic. 15.4). Disengage the pump sprocket from the chain and remove the oil pump from the engine.

Pic. 15.4. Mark the installation position of each oil pump mounting bolt (marked with arrows) while unscrewing it (engines 2.0 l)

Inspection

5. Inspect the oil pump sprocket for signs of damage and wear, such as chipped or missing teeth. If the sprocket is worn, the pump assembly must be replaced as the sprocket is not supplied separately. In addition, it is recommended to simultaneously replace the chain and the drive sprocket located on the crankshaft. The oil pump drive sprocket and chain can be removed without removing the engine from the vehicle after removing the crankshaft sprocket and crankshaft seal housing. For more information, please refer to chapter 2D.

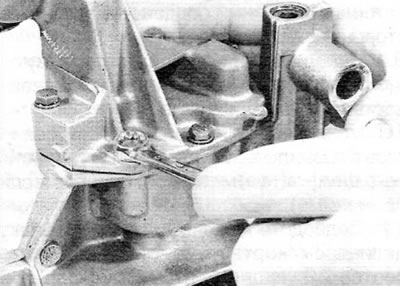

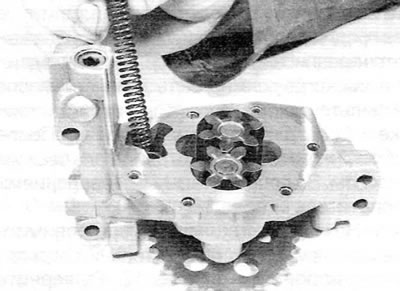

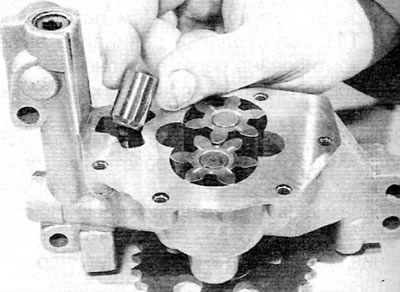

6. Loosen and remove the strainer cover bolts to the pump housing and remove the strainer cover. Remove the piston and safety valve spring (and guide pin - only on 2.0 l engines), noting for yourself how they are installed (pic. 15.6, a-c).

Pic. 15.6, a. Loosen the bolts...

Pic. 15.6, b.... remove the cover, spring...

Pic. 15.6, c....and the safety valve piston, noting for yourself how it is located

7. Inspect impellers and pump housing for signs of wear and tear. If there is wear, replace the pump assembly.

8. Inspect the relief valve piston for signs of wear or damage and replace if necessary. The condition of the safety valve spring can only be assessed by comparing it with a new one. If there is any doubt about the condition, it should also be replaced. The piston and spring are supplied separately.

9. Thoroughly clean the oil pump strainer with a suitable solvent and check for signs of blockage or damage. If the filter is damaged, the mesh filter assembly with cover must be replaced.

10. Install the relief valve spring and piston and guide pin (in the presence of) into the strainer cover. Install the cover on the pump housing. Align the relief valve plunger with the corresponding mounting hole in the pump. Install the cover bolts and tighten them securely.

Installation

11. On 1.9L engines, install the spacer plate, and then drive the pump into place by engaging the pump sprocket with the drive chain. Screw the pump mounting bolts (the longer bolt should be screwed into the rear hole) and tighten them to the prescribed torque.

12. On 2.0L engines, engage the pump sprocket with the drive chain, and then screw in the bolts. Install the sealing washer on the rear bolt, and then screw in the pump mounting bolts, installing them in their original position. Tighten the bolts to the specified torque.

13. On all engines, install the dipstick guide tube to the cylinder block and securely tighten the appropriate bolt.

14. Install the oil pan as described in paragraph 14.