Note. To properly adjust the timing belt tension, Peugeot/Citroen prescribes the use of a special electronic tool (belt tension measuring tool SEEM C.TRONIC, type 105). The following procedure is based on the use of this equipment (or equivalent alternative equipment calibrated to measure belt tension in SEEM units).

Timing belt tension accuracy is very important, and if electronic equipment is not available, it is recommended that this work be done by a Peugeot/Citroen dealer or service station that has the appropriate equipment.

General information

1. The timing belt drives the camshaft, high pressure fuel pump and coolant pump from the toothed pulley at the right end of the crankshaft. In addition, the belt drives the brake vacuum pump, not directly, but from the camshaft on the flywheel side. If the belt breaks or slips during operation, the pistons can come into contact with the valve heads, resulting in extensive damage resulting in costly repairs.

2. The timing belt should be replaced at prescribed intervals or sooner if it is contaminated with oil or makes noise when running (squeal/creak due to uneven wear).

3. If the timing belt is removed, it is recommended to check the condition of the coolant pump at the same time (check for signs of coolant leakage). This will help avoid the need to remove the belt at a later stage if the coolant pump fails.

Removing

4. Remove the upper, intermediate and lower timing belt covers as described in paragraph 6.

5. Align the mounting holes for the engine/camshaft assembly as described in paragraph 3, and lock the camshaft sprocket hub, injection pump hub and flywheel. Do not attempt to crank the engine with the locking bars installed.

6. Loosen the three bolts securing the camshaft sprocket to the sprocket hub (pic. 7.6).

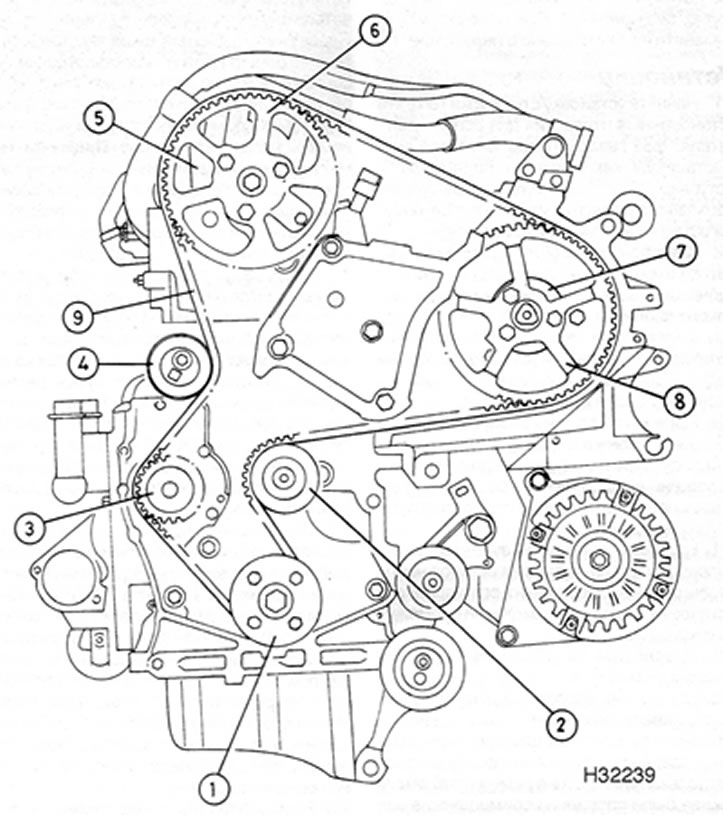

Pic. 7.6. Timing belt, toothed pulley and tensioner (engines 1.9 l)

1. Crankshaft pulley

2. Intermediate pulley

3. Coolant pump sprocket

4. Idler pulley

5.Camshaft sprocket hub

6. Camshaft pulley

7. High pressure fuel pump sprocket hub

8. High pressure fuel pump sprocket

9. Belt gas distribution mechanism

7. Similarly release three bolts of fastening of a gear pulley of the high pressure fuel pump to a nave of the pump.

8. Loosen the timing belt tensioner pulley bolt. Turn the pulley clockwise using a square wrench inserted into the hole in the pulley hub, and then tighten the bolt again.

Advice. If you're having trouble getting a square tool to fit into the idler pulley, buy an 8mm square rod for a standard doorknob at the hardware store and shorten it to the correct length (A). Insert a rod into the pulley hub and rotate the pulley with an 8mm wrench (IN).

9. If the timing belt is to be used further, mark the direction of rotation on the belt with white paint or a marker (if the marking is not visible). Remove the belt from the toothed pulleys. Keep in mind that you should not turn the crankshaft with the belt removed.

10. Carefully check the timing belt for signs of uneven wear, separation or oil contamination. Pay special attention to tooth cavities. Replace the belt if there is even the slightest doubt about its condition. If the engine is overhauled, replace the belt without fail, regardless of its external condition. The cost of a new belt is not comparable to the cost of repairing an engine in the event of a broken belt. If signs of oil contamination are found, locate the leak and repair the cause of the leak. Wash the engine in the area of the timing belt, as well as all relevant elements until all traces of oil are completely removed. Check that the tensioner and pulleys rotate freely without binding. If necessary, replace them as described in paragraph 9.

Installation

11. Begin installation by checking that the engine/camshaft assembly mounting holes are still aligned as described in paragraph 3, and the camshaft sprocket hub, injection pump hub and flywheel are stuck.

12. Slightly tighten the camshaft sprocket and high pressure fuel pump sprocket bolts just enough so that the gear pulleys can still move within their respective elongated slots. Turn both toothed pulleys clockwise to the end of the grooves.

13. Bring the timing belt to its normal position, while the arrows on the belt should point in the direction of rotation of the belt (clockwise when viewed from the right end of the engine).

14. Slide the belt over the crankshaft sprocket, being careful not to twist it sharply during installation, and slide the belt over the idler pulley.

15. Make sure that the front section of the belt is tensioned, and then set the belt against the gear pulley of the high pressure fuel pump. Turn the toothed pulley counterclockwise on the corresponding hub until the teeth of the belt and toothed pulley are properly aligned, and then slide the belt onto the toothed pulley. Note. Do not turn the sprocket counterclockwise more than necessary, and never turn it more than one tooth on the sprocket.

16. After the belt is correctly put on the high pressure fuel pump sprocket, make sure that «front» And «upper» sections are tensioned, and then align the belt with the camshaft sprocket. Rotate the camshaft sprocket counterclockwise on the corresponding hub until the teeth of the belt and gear wheel are properly aligned, and then slide the belt onto the sprocket. Note. Do not turn the sprocket counterclockwise more than necessary, and never turn it more than one tooth on the sprocket.

17. Make sure that all the slack in the belt is on the side where the idler pulley is located, and then put the belt on the coolant pump gear pulley and slide it behind the idler pulley.

18. Make sure that the teeth of the belt are centered on the toothed pulleys, and loosen the bolt securing the idler pulley. Turn the pulley counter-clockwise to completely remove the slack in the timing belt, and then retighten the bolt.

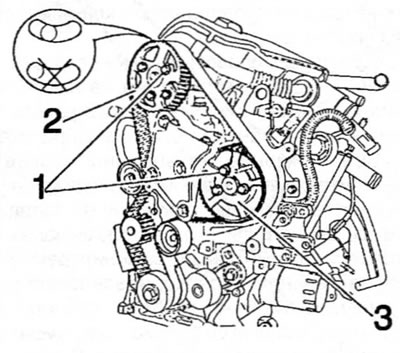

19. Turn out on one of bolts of fastening of gear pulleys of the fuel pump of a high pressure and a camshaft and be convinced that gear pulleys are brought to a stop in grooves for bolts (pic. 7.19). If retracted, the toothed pulleys were rotated more than one tooth when the belt was installed. Remove the timing belt and repeat the installation procedure. If the toothed pulleys are correctly positioned, tension the timing belt as described below.

Pic. 7.19. Remove one of the bolts (1) on the camshaft pulleys (2) and high pressure fuel pump (3) and make sure that the toothed pulleys do not go all the way into their respective grooves (see callout) (engines 1.9 l)

20. Bring the sensor head of the electronic equipment for measuring belt tension to the upper section of the timing belt, approximately in the middle between the gear pulleys of the high pressure fuel pump and the camshaft.

21. Turn the idler pulley counterclockwise until the gauge display shows an initial tension of 106±2 SEEM units. Hold the idler pulley in this position and tighten the bolt again.

22. Make sure that the toothed pulleys have not been rotated so that the bolts have reached the edge of the slots. If so, repeat the installation procedure. If everything is in order, tighten the camshaft pulley and high pressure fuel pump bolts to the prescribed torque.

23. Remove the belt tension measurement equipment and tools to lock the crankshaft, camshaft sprocket hub, and high pressure fuel pump hub.

24. Turn the crankshaft 8 full turns clockwise (viewed from the right side of the engine). Align the engine/camshaft assembly mounting holes again and insert the crankshaft, camshaft, and injection pump locking tools.

25. Loosen the camshaft and high pressure fuel pump sprocket bolts, tighten them by hand, and then loosen them all one sixth of a turn.

26. Loosen the idler pulley mounting bolt again. Position the belt tension measuring equipment at the top of the belt and turn the idler pulley to achieve a final setting of 42±2 SEEM. Hold the idler pulley in this position and tighten the bolt to the specified torque.

27. Tighten all toothed pulley bolts to the specified torque.

28. Retract the sensing head of the belt tension measurement equipment, and then bring it back to the belt and check for an indication in the range of 38-46 SEEM units. Remove measuring equipment.

29. Remove the blocking tools, and then turn the crankshaft again two full turns clockwise. Align the engine/camshaft assembly mounting holes again and insert the crankshaft locking tool.

30. Verify that tools can be inserted to lock the camshaft sprocket hub and high pressure fuel pump hub. If inserting tools fails, check that the misalignment between the locating holes in the toothed pulley hubs and the mating holes in the cylinder head and high pressure fuel pump is less than 1.0 mm. If it exceeds, completely repeat the procedure for installing and tensioning the timing belt.

31. Install the lower, intermediate and upper timing belt covers as described in paragraph 6.

32. Install the crankshaft pulley as described in paragraph 5.