Withdrawal (engines 1.9 l)

1. Remove the accessory drive belt as described in chapter 1B.

2. Turn out four bolts of fastening of a pulley of a cranked shaft and remove a pulley, having noted for itself how it is installed.

Installation (engines 1.9 l)

3. Install the pulley on the end of the crankshaft, orienting it correctly. Apply locking compound (Peugeot/Citroen recommends Loctite Frenetanch) on the threads of the corresponding bolts, then screw in the bolts and tighten them to the prescribed torque.

4. Install and tension the accessory drive belt as described in chapter 1B.

Withdrawal (engines 2.0 l)

5. Remove the accessory drive belt as described in chapter 1B.

6. It is now necessary to determine the type of pulley installed, as two different removal and installation procedures are provided accordingly.

7. From under the wheel arch, look at the flat face of the pulley. If it has a mark made with green paint, it is a later type of pulley. If there is no mark, it is an early pulley. Proceed as described below depending on the pulley type.

Pulley without green mark

8. To prevent the crankshaft from turning when the pulley bolt is released, lock the flywheel ring gear with a suitable tool made of steel strip. Release the power steering fluid lines from the clips on the cover at the base of the front section of the transaxle case. Remove the cover from the flywheel housing and bolt the tool through the lower threaded hole in the flange of the front section of the gearbox housing so that it engages with the ring gear teeth.

Tip: The flywheel ring gear locking tool can be made from a short strip of steel bent at right angles. Cut a groove in the top section and fold back this part to then engage it with the teeth of the ring gear. File the folded edge to give it a tooth profile. Drill a hole in the lower section so that the tool can be bolted to the flange of the front section of the transaxle case.

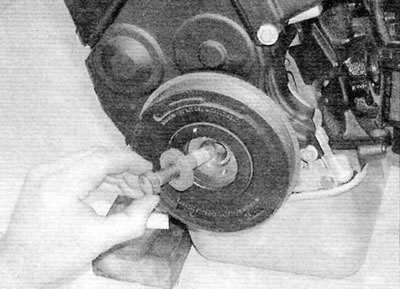

9. Using a suitable socket and extension, remove the bolt, remove it along with the washer and remove the pulley from the end of the crankshaft (pic. 5.9). If the pulley is tight, you can loosen the crankshaft using a suitable puller. If a puller is used, install the pulley bolt without a washer to avoid damage to the crankshaft when tightening the puller.

Pic. 5.9. Turn out a bolt, remove it together with a washer and remove a crankshaft pulley (engines 2.0 l)

Pulley with green mark

10. Align the mounting holes for the engine/camshaft assembly as described in paragraph 3, and lock the crankshaft and camshaft sprocket. The later crankshaft sprocket has a wider keyway. When the pulley bolt is loosened, the toothed pulley can rotate on the crankshaft as far as the wider keyway allows. This allows some lateral movement of the toothed pulley to fine-tune the timing belt tension. Therefore, when releasing the pulley bolt, it is necessary that the flywheel and camshaft be locked in the engine assembly / camshaft setting position, otherwise the toothed pulleys will rotate slightly and the valve timing will be «shot down».

11. To prevent rotation of the crankshaft when the pulley bolt is released, fabricate and install the tool to stop the flywheel ring gear, as described in paragraph 8. Do not attempt to use tools to prevent rotation when the bolt is released, tools to lock in the engine assembly position / adjust the valve timing.

12. Using a suitable socket and extension, remove the bolt, remove it with the washer, and then remove the pulley from the end of the crankshaft. If the pulley is tight, you can loosen the crankshaft using a suitable puller. If a puller is used, install the pulley bolt without a washer to avoid damage to the crankshaft when tightening the puller.

Installation (engines 2.0 l)

13. When working with a later style pulley, take care that the engine/camshaft assembly mounting holes are still aligned as described in paragraph 3, and the crankshaft and camshaft pulleys were stuck.

14. Install the pulley on the end of the crankshaft.

15. Thoroughly clean the pulley bolt threads, then apply locking compound to the bolt threads (Peugeot/Citroen recommends Loctite Frenetanch).

16. Screw in the crankshaft pulley bolt (do not forget to put the puck). Tighten the bolt to the specified torque, and then turn to the specified angle while holding the crankshaft from turning with the tool that was used for removal. Please note that different tightening torques and angles are specified in «Specifications» depending on the type of pulley.

17. Remove the flywheel ring gear locking tool and, if applicable, the tools used to lock the crankshaft and camshaft gear pulleys.

18. Install the cover on the front section of the gearbox housing and secure the power steering fluid lines.

19. When working with a later type pulley, install the upper timing belt cover as described in paragraph 6.

20. Install and tension the accessory drive belt as described in chapter 1B.