Removing

1. Disconnect the ground wire from the battery (see «Disconnecting the battery»).

2. Align the mounting holes for the engine/camshaft assembly as described in paragraph 3, and lock the hub (-s) toothed pulley (-ov) and flywheel.

Warning. Do not attempt to crank the engine with the locking bars installed.

3. Remove the timing belt as described in paragraph 7 or 8 (whichever is applicable), and then continue as described under the appropriate subheading.

Camshaft pulley

4. As a precaution, remove the flywheel locking tool and then reverse the crankshaft (counterclock-wise) 90°. This will bring the pistons into the mid-stroke position and eliminate the possibility of the valves hitting the pistons in subsequent steps.

5. Loosen the bolt securing the toothed pulley hub and the three bolts securing the toothed pulley to the hub (if applicable). To prevent the camshaft from turning when the bolt is released, you will need to hold the toothed pulley. In the absence of a special Peugeot / Citroen tool, an acceptable replacement can be made by yourself. Do not attempt to use a tool inserted into the engine/camshaft assembly mounting hole to prevent the toothed pulley from turning when the bolt is released.

6. Turn out a bolt of fastening of a nave of a gear pulley and remove a gear pulley and a nave from the end of a camshaft. If the segment key is loose, remove it and store it in a safe place. Inspect the camshaft seal for signs of oil leakage and, if necessary, replace it as described in paragraph 10.

7. If necessary, on engines with a two-piece toothed pulley, the pulley can be separated from the hub after removing these three bolts.

High pressure fuel pump sprocket (engines 1.9 l)

8. Turn out three bolts and remove a gear pulley from a corresponding nave; The hub is an integral part of the high pressure fuel pump.

High pressure fuel pump sprocket (engines 2.0 l)

9. Loosen the nut securing the toothed pulley, holding the toothed pulley from turning with a holding tool (see point 5).

10. Then the toothed pulley should be removed from the high pressure fuel pump shaft using a puller. In the absence of a proper Peugeot/Citroen puller or a suitable replacement, an alternative can be made from a short steel plate.

11. Loosen the nut of the sprocket, and then secure the steel plate to the sprocket by screwing two M7 bolts into the threaded holes provided. Tighten the bolts evenly until the plate comes into contact with the nut, and then loosen the sprocket nut to remove the sprocket from the pump shaft. As soon as the toothed pulley is released, unscrew the bolts and remove the plate, and then unscrew the nut and remove the toothed pulley (pic. 9.11, a-c).

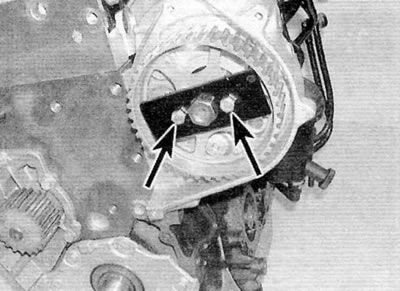

Pic. 9.11, a. Slide the plate onto the toothed pulley nut and screw in the two bolts (marked with arrows) (engines 2.0 l)

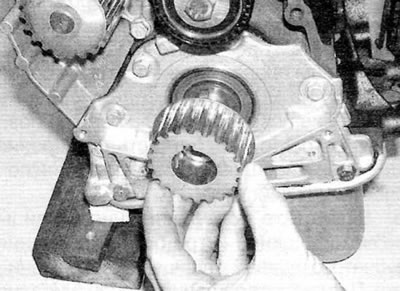

Pic. 9.11, b. With the puller installed, hold the toothed pulley, and then unscrew the toothed pulley fixing nut to separate the pulley from the pump shaft (engines 2.0 l)

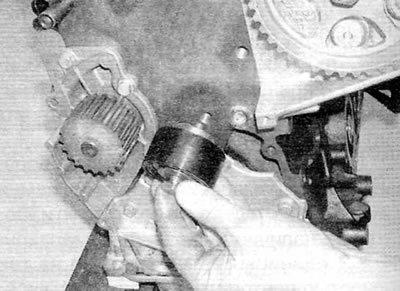

Pic. 9.11, c. After releasing the toothed pulley, remove the puller, and then unscrew the nut and remove the toothed pulley (engines 2.0 l)

Crankshaft pulley (engines 1.9 l)

12. As a precaution, remove the flywheel locking tool and then reverse the crankshaft (counterclock-wise) 90°. This will bring the pistons into the mid-stroke position and eliminate the possibility of the valves hitting the pistons in subsequent steps.

13. Release a bolt of fastening of a gear pulley of a cranked shaft. To prevent crankshaft rotation, select a higher gear and have an assistant fully depress the brake pedal. Alternatively, the flywheel ring gear can be blocked using a suitable tool made from steel strip.

14. Turn out a bolt and remove it together with a corresponding washer, and then remove a gear pulley from the end of a cranked shaft. If the segment key is not secured to the crankshaft, remove it and store it in a safe place along with the toothed pulley. Inspect the crankshaft seal for signs of oil leakage and replace if necessary as described in paragraph 17.

Crankshaft pulley (engines 2.0 l)

15. Remove the toothed pulley from the end of the crankshaft. If the segment key is not secured in the crankshaft, remove it and store it in a safe place along with the toothed pulley (pic. 9.15, a, b). Inspect the crankshaft seal for signs of oil leakage and replace if necessary as described in paragraph 17.

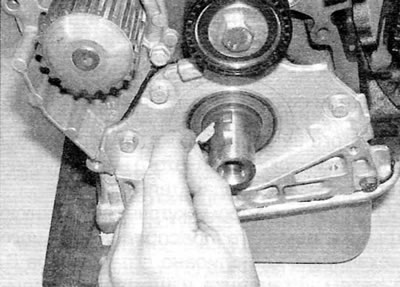

Pic. 9.15 a. Remove the sprocket from the crankshaft...

Pic. 9.15 b....then remove the segmented key (engines 2.0 l)

Coolant pump sprocket

16. The coolant pump sprocket is integrated with the pump and cannot be removed from it. Remove the coolant pump as described in chapter 3.

Idler pulley

17. Turn out a bolt and remove a pulley from a basic hairpin. Inspect the support pin for signs of damage and replace if necessary.

Intermediate pulley

18. Turn out a bolt and remove an intermediate pulley from the block of cylinders (pic. 9.18).

Pic. 9.18. Turn out a bolt and remove an intermediate pulley from the block of cylinders

Inspection

19. Thoroughly clean toothed pulleys and replace those that show signs of wear, damage or cracks.

20. Clean the idler pulley and intermediate pulley, but do not use strong solvents that can penetrate the pulley bearings. Check that the pulleys rotate freely about their respective hubs, with no signs of binding or play. Replace the pulley if there is any doubt about its condition or if there are obvious signs of wear or damage.

21. Inspect the timing belt (see pparagraph 7 or 8). Replace the belt if there is any doubt about its condition.

Installation

Camshaft pulley

22. On engines with a two-piece pulley, install the toothed pulley on the hub (if it was taken) and secure it with three bolts, tightening them at this stage only by hand.

23. Install the key on the end of the camshaft, and then install the camshaft sprocket and corresponding hub.

24. Screw in the bolt of the toothed pulley hub (remember to install the appropriate washer). Tighten the bolt to the specified torque, keeping the camshaft from turning, as when removing.

25. Align the mounting hole in the hub with the mating hole in the cylinder head and insert the locking tool. Rotate the crankshaft 90°clockwise and lock the flywheel with a blocking tool.

26. Install the timing belt (see paragraph 7 or 8).

High pressure fuel pump sprocket (engines 1.9 l)

27. Install the toothed pulley on the hub and lightly tighten the appropriate bolts.

28. Install the timing belt (see paragraph 7).

High pressure fuel pump sprocket (engines 2.0 l)

29. Clean and dry the beveled surfaces of the pump shaft and toothed pulley and install the toothed pulley to the pump. Install the toothed pulley nut and tighten to the specified torque using a holding tool to prevent turning.

30. Install the timing belt (see paragraph 8).

Crankshaft pulley (engines 1.9 l)

31. Install the key on the end of the crankshaft (if removed).

32. Align the groove in the crankshaft pulley with the segment key and put it on the end of the crankshaft.

33. Remove all traces of locking compound from the pulley and crankshaft bolt threads. Apply locking compound (Peugeot/Citroen recommends Loctite Frenetanch) on the thread of the bolt, and then screw the bolt (don't forget to install the washer) into the crankshaft.

34. Tighten the bolt to the specified torque according to step 1, while preventing the crankshaft from turning as it would during removal.

35. Using a socket and extension, tighten the pulley mounting bolts to the specified angle according to stage 2. To ensure accuracy at this stage of tightening, it is recommended to use a goniometer.

36. Rotate the crankshaft 90°clockwise and lock the flywheel with a locking tool.

37. Install the timing belt (see paragraph 7).

Crankshaft pulley (engines 2.0 l)

38. Install the key on the end of the crankshaft, if removed.

39. Align the groove in the crankshaft pulley with the key and slide the pulley onto the end of the crankshaft.

40. Install the timing belt (see paragraph 8).

Idler pulley

41. Install the idler pulley on the support pin and screw in the appropriate bolt.

42. Install the timing belt (see paragraph 7 or 8).

Intermediate pulley

43. Install the intermediate pulley on the cylinder block and tighten the appropriate mounting bolt to the prescribed torque.

44. Install the timing belt (see paragraph 7 or 8).