General information

1. The timing belt tensioner operates under the action of a spring and a plunger located in the bracket of the right engine mount, which is bolted to the end surface of the engine. The engine support is attached to the support on the body with the help of an appropriate bracket.

Bracket for fastening the right engine mount to the body

Removing

2. Support the engine before removing the bracket. For this, it is best to use a suitable lifting device, the slings/hooks of which should be connected to the rigging bracket at the right end of the engine. Alternatively, the engine can be supported with a rolling jack under the oil pan, with a piece of wood between them. In this case, you should be prepared for the fact that the engine will tend back after removing the bracket.

3. Loosen the clamps and brackets and position the booster pump and related hoses and wires away from the engine mount and upper suspension mount.

4. Remove three nuts securing the support bracket to the engine support bracket and one nut securing the bracket to the rubber support on the body, and then remove the bracket (pic. 9.4).

Pic. 9.4. Removing the engine mount bracket to the body

Installation

5. Installation is carried out in the reverse order of removal. Tighten nuts and bolts to specified torque.

Timing Belt Tensioner and Right Engine Mount Bracket

Note. You will need an appropriate tool to hold the timing belt tensioner plunger while performing this procedure.

Removing

6. Remove the engine mount-to-body bracket as described earlier in this paragraph and remove the accessory drive belt as described in chapter 1B.

7. If you have not already done so, support the engine with a jack under the oil pan with a piece of wood underneath.

8. If applicable, disconnect the hoist straps/hooks supporting the engine from the right rigging bracket (this is necessary because the rigging bracket is attached to the engine mount bracket and must be removed).

9. Turn out two bolts and remove a lifting arm of the engine.

10. Align the engine/camshaft assembly mounting holes as described in paragraph 3, and lock the camshaft sprocket, injection pump sprocket and flywheel. Do not crank the engine with the rods installed.

11. Loosen the timing belt tensioner axle nut and adjusting bolt, and then turn the tensioner bracket counterclockwise until the adjusting bolt is in the middle of the groove and tighten the adjusting bolt again. To rotate the tensioner bracket against the force of the spring, use a 10mm square-head wrench to be inserted into the hole provided.

12. If the timing belt is to be used further, mark the direction of rotation on the belt. Remove the belt from the toothed pulleys.

13. Now you should purchase a tool to hold the tensioner plunger in the engine mount bracket.

14. A Peugeot/Citroen special tool is available to insert into the two holes for the lower support bracket mounting bolts. You can easily make a similar tool from sheet metal using 10mm bolts and nuts instead of metal rods

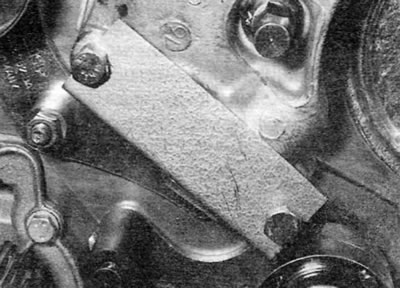

Tip: A homemade tool to hold the tensioner plunger in the engine mount bracket.

15. Remove the two lower motor support bracket bolts and install the special tool (pic. 9.15, a, b). Lubricate the inside of the tool to prevent any damage to the end of the tensioner plunger. Loosen the axle nut and adjusting bolt and remove the tensioner.

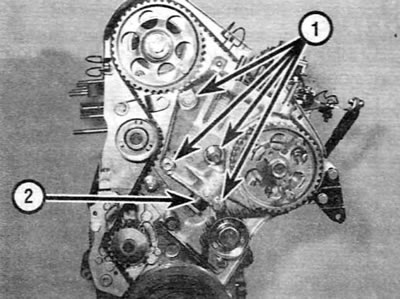

Pic. 9.15 a. The side of the engine on which the timing belt is located

1. Engine support bracket bolts

2. Timing belt tensioner plunger

Pic. 9.15 b. Tool for holding the tensioner plunger in the engine mount bracket (timing belt removed for clarity)

16. Turn out two remained bolts of fastening of a basic arm of the engine and remove an arm.

17. Squeeze the tensioner plunger into the engine support bracket, remove the special tool, and then remove the plunger and spring.

Installation

18. Installation is carried out in the reverse order of removal, taking into account the following points:

- A) Tighten all nuts/bolts to the specified torque.

- b) Install and tension the timing belt as described in paragraph 7.

- V) Install and tension the accessory drive belt as described in chapter 1B.