Removing

1. Remove the cylinder head cover as described in paragraph 4.

2. Remove the camshaft sprocket as described in paragraph 8.

3. Remove the brake vacuum pump as described in chapter 9.

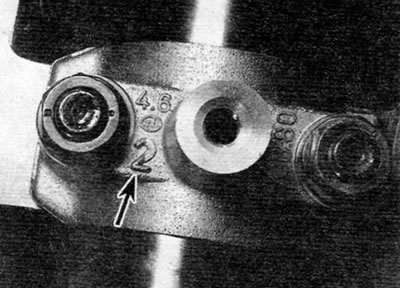

4. The camshaft bearing caps must be numbered from the end of the engine where the flywheel is located (pic. 11.4). If the covers are not numbered, identify them starting at the flywheel side and mark on the side facing the manifold.

Pic. 11. 4. Identification mark (marked with an arrow) on the camshaft bearing cap

5. Gradually turn away nuts, and then remove covers of bearings.

6. Remove the camshaft from the cylinder head. Remove the cuff from the end of the camshaft where the timing belt is located. Discard the cuff, use a new one when installing.

7. Prepare eight small clean plastic containers and number them from 1 to 8. Alternatively, divide the large container into eight compartments. Using a rubber suction cup, remove all pushers one by one and place them in the containers provided. Do not confuse the pushers, this can lead to accelerated wear. If necessary, also remove the shim from the top end of the valve stem and store it with the appropriate tappet. Be aware that the shim may stick to the inside of the pushrod when it is removed. In this case, be careful that it does not fall out when removing the pusher.

Inspection

8. Inspect the working surfaces of the camshaft bearings and cams for signs of wear and scoring. If any of these conditions are present, replace the camshaft. Check the condition of the running surfaces of the bearings on the camshaft journals and in the bearing caps/cylinder head. If the bearing surfaces in the cylinder head show excessive wear, the cylinder head must be replaced.

9. Inspect the surfaces of the tappets that are in contact with the camshaft lobes for wear and tear. Replace pushrod if this condition exists. If the tappet face is badly scratched, also inspect the corresponding cam on the camshaft for wear, as both elements are likely to be worn. If necessary, replace the required elements.

Installation

10. To prevent any possibility of valve contact with the pistons when installing the camshaft, remove the blocking rod/drill from the flywheel and rotate the crankshaft a quarter of a turn in the opposite direction of normal rotation to position all pistons in the middle of the stroke. Remove the timing belt from the high pressure fuel pump sprocket while turning the crankshaft.

11. Install shims (if they were removed) on the upper ends of the valve stems, following the original position. Do not mix up the shims, as this will cause a misalignment of the valve clearances (see paragraph 12).

12. Copiously lubricate the holes for the hydraulic tappets in the cylinder head and the tappets themselves. Carefully insert the tappets into the bores in the cylinder head, ensuring that each tappet is seated in its original hole. Some care will be required to insert the tappets into the holes without being skewed.

13. Lubricate the bearing journals and camshaft cams with clean engine oil of the prescribed grade.

14. Install the camshaft in the cylinder head, passing it through the engine front plate.

15. Temporarily install the toothed pulley on the end of the camshaft and rotate the shaft so that the mounting hole in the toothed pulley is aligned with the corresponding cutout in the cylinder head. Remove the toothed pulley.

16. Install the center bearing cap as noted during removal, and then screw on the nuts and tighten them two or three turns.

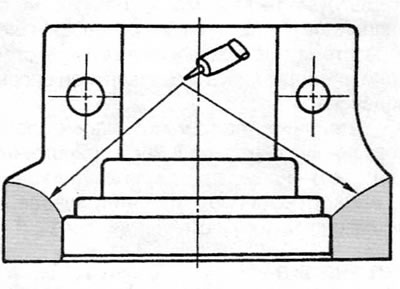

17. Apply sealant to the outer bearing caps at the locations shown (pic. 11.17). Install them in the correct position and tighten the nuts two or three turns.

Pic. 11.17. Apply sealant to the outer camshaft bearing caps at the locations shown

18. Gradually tighten all nuts to the prescribed torque, making sure that the camshaft remains in the correct position.

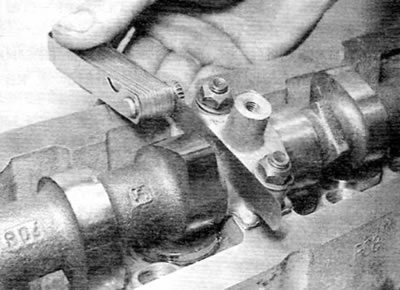

19. Make sure that the axial clearance of the camshaft corresponds to that specified in «Specifications», using a fan» probe If the clearance does not match, replace the camshaft and/or cylinder head. To check the end play, fully press the camshaft toward one end of the cylinder head and insert a feeler gauge between the thrust surfaces of one of the camshaft cams and the bearing cap (pic. 11.19).

Pic. 11.19. Checking the axial clearance of the camshaft using «fan» probe

20. If the removed camshaft is returned to its place and it is confirmed that the valve clearances are correct, go to the next step. If not, check and adjust valve clearances as described in paragraph 12.

21. Lubricate the sealing lips of the new cuff with clean engine oil, fit the cuff onto the end of the camshaft so that the sealing lip faces inward. Press the collar until it is flush with the end face of the camshaft bearing cap.

22. Install the brake vacuum pump as described in chapter 9.

23. Temporarily mount the toothed pulley again on the end of the camshaft and make sure that the mounting hole in the toothed pulley is aligned with the corresponding cutout in the cylinder head.

24. Turn the crankshaft a quarter of a turn in the normal direction of rotation so that pistons No. 1 and 4 are back at TDC.

25. Insert a rod/drill into the mounting hole in the flywheel.

26. Install the camshaft sprocket as described in paragraph 8.

27. Install the cylinder head cover as described in paragraph 4.