Models with 1.9L WJZ engine

1. The fuel system includes a fuel tank (installed at the back of the car), fuel filter with integrated water separator, high pressure fuel pump, injectors and related items.

2. The high pressure fuel pump draws fuel from the tank through the fuel filter, which is mounted on the thermostat housing at the left end of the cylinder head. The fuel filter removes all dirt and water and keeps the fuel supplied to the high pressure fuel pump clean. Excess fuel returns from the outlet on the filter housing cover to the tank. A thermostat is built into the filter housing. When the temperature of the fuel in the filter housing is below 15°C, the thermostat in the filter housing opens and allows the fuel to circulate between the filter housing and the thermostat housing, which ensures efficient fuel heating. When the fuel in the filter housing reaches 35°C, the thermostat closes.

3. The high pressure fuel pump is driven by the timing belt. Its speed is equal to half the speed of the crankshaft. The high pressure required to inject the jet of fuel into the charge of compressed air contained in the swirl chambers is created by opposed pistons moving forward towards each other. The injection of fuel occurs as a result of the action on the pistons of the roller pushers running on the cams of the rotor. Fuel flows through a central rotor with a single outlet that mates with ports directed to the injector piping.

4. Fuel metering is controlled by a centrifugal governor that responds to the accelerator pedal position and engine speed. The regulator is connected to a metering valve that increases or decreases the amount of fuel supplied with each stroke of the pump.

5. Basic fuel injection advance is set when the pump is installed. When the engine is running, it is automatically changed to match the prevailing engine speed by a special actuator that turns the cam plate or cam ring.

6. Four fuel injectors deliver fuel in a uniform jet to swirl chambers located in the cylinder head. The nozzles are calibrated to open and close at critical pressure to ensure efficient and even combustion. The needle of each nozzle is lubricated with fuel, which accumulates in the spring chamber and is directed through the bypass pipelines to the return hose of the high pressure fuel pump.

7. Cold start is facilitated by a pre-heater or glow plugs installed in each swirl chamber. A thermostatic sensor in the cooling system acts on the fast idle lever on the high pressure fuel pump to increase the idle speed when the engine is cold.

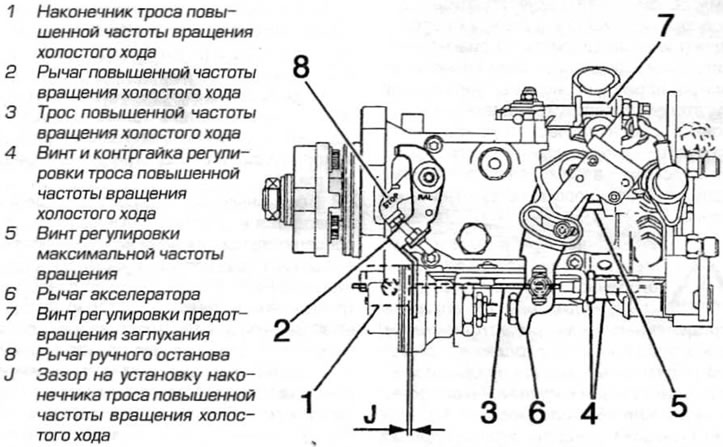

8. The stop solenoid shuts off fuel to the high pressure fuel pump rotor when the ignition is turned off. There is also a manual stop lever for use in an emergency (pic. 1.8).

Pic. 1.8. Lucas high pressure fuel pump (models with 1.9 l WJZ engine)

9. Provided that the prescribed maintenance is performed, the fuel injection equipment will provide long-term trouble-free operation. The high pressure fuel pump itself can last longer than the engine. The main potential cause of damage to the high pressure fuel pump and injectors is the presence of dirt or water in the fuel.

10. The engine is equipped with a catalytic converter and an exhaust gas recirculation system (EGR), which reduce the toxicity of exhaust gases. For more information, please refer to chapter 4D.

11. Maintenance of the high pressure fuel pump and injectors is generally beyond the competence of an amateur mechanic. All removal or adjustment procedures other than those described in this chapter should be referred to a Peugeot/Citroen dealer or fuel injection specialist.

Attention! When working on fuel system components, especially fuel injectors, certain precautions must be taken. Before any work on the fuel system, refer to the precautions described at the beginning of the Manual in paragraph «Safety first!», and any additional warnings given at the beginning of the relevant paragraphs, and follow them.

Models with 1.9L WJY engine

12. Later 1.9L engines (WJY) Equipped with an electronically controlled high-pressure fuel pump to reduce emissions and meet emission standards to be introduced in the near future. The fuel system is very similar to that described in p.p. 1-11. except for the following changes regarding the high pressure fuel pump.

13. The electronic control system of the high pressure fuel pump includes the BEU and the following sensors:

- A) throttle potentiometer; it informs about the relative position of the accelerator lever on the high pressure fuel pump and the opening/closing speed «throttle valve»;

- b) air flow sensor (it has a built-in air intake temperature sensor); it informs the BEU about the flow rate and temperature of the air passing through the intake tract;

- V) coolant temperature sensor; it informs the BEU about the engine temperature;

- G) crankshaft position sensor; it informs the BEU about the angular position and speed of the engine crankshaft:

- d) vehicle speed sensor: it informs the ECU about the vehicle speed:

- e) injector needle lift sensor: it informs the ECU about the start of injection in cylinder No. 7;

- and) atmospheric pressure sensor (built into BEU); it measures atmospheric pressure to prevent problems when driving at high altitudes.

14. All signals from the sensors are analyzed by the BEU, which controls the fuel injection advance using the advance solenoid valve, which is located on the high pressure fuel pump. By opening and closing the solenoid valve, the BEU can, as necessary, increase or decrease the fuel injection advance. When the advance solenoid valve is open, the hydraulic pressure on the pump piston decreases, resulting in a decrease in fuel injection advance. To increase the fuel injection advance, the BEU closes the solenoid valve, which increases the pressure on the piston.

15. BEU also manages the exhaust gas recirculation system (EGR), described in detail in chapter 4D, and an engine cooling fan.

16. If there are any anomalies in any of the signals received from various sensors, the BEU enters «spare» mode. If this happens, the erroneous sensor signal is ignored and the ECU assumes a pre-programmed default value that allows the engine to continue running but with reduced power. If the BEU enters this mode, the control lamp on the instrument panel turns on and the corresponding fault code is recorded in the BEU memory.

17. If the warning light is on, have the vehicle checked by a Peugeot/Citroen dealer or an engine diagnostician as soon as possible. The technician can perform a complete check of the engine management system using a dedicated electronic diagnostic tester that plugs into the diagnostic socket located next to the passenger compartment fuse box.

Attention! When working on fuel system components, especially fuel injectors, certain precautions must be taken. Before any work on the fuel system, refer to the precautions described at the beginning of the Manual in paragraph «Safety first!», and any additional warnings given at the beginning of the relevant paragraphs, and follow them.

Models with 2.0L engine

18. All 2.0L engines are equipped with a diesel fuel injection system (HDi), which implements the latest advances in diesel fuel injection technology. In the HDi system, the high pressure fuel pump is only used to generate the pressure required by the injection system and has no control over fuel injection timing (unlike conventional diesel fuel injection systems). Fuel injection advance is controlled by an electronic control unit (BEU) through electric injectors. The system works as described below.

19. The composition of the fuel system includes a fuel tank (installed under the rear of the vehicle, into which, on the Bosch system, the low pressure electric fuel pump is immersed), fuel filter with integrated water separator, high pressure fuel pump, injectors and related items.

20. Fuel is supplied to the fuel filter housing, which is located on the front of the engine. The fuel filter removes all dirt and water and cleans the fuel supplied to the high pressure fuel pump. Excess fuel returns from the outlet on the filter housing cover to the tank through the fuel cooler. The cooler is mounted on the bottom of the vehicle and is cooled by passing air to cool the fuel before it enters the fuel tank.

21. To prevent starting problems at very low outside temperatures, the fuel is heated. On early models, the filter housing is connected to the coolant distribution housing located on the left end of the cylinder head and is fitted with a thermostat. When the temperature of the fuel in the filter housing is below 15°C, the filter housing thermostat opens and allows the fuel to circulate around the coolant distribution housing, which effectively heats the fuel. When the temperature of the fuel in the filter housing reaches 25°C, the thermostat closes. Later models use an electric fuel heater that is connected to the fuel supply line on the filter housing. The heater is controlled by BEU.

22. The high pressure fuel pump is driven by the timing belt. Its speed is equal to half the speed of the crankshaft. High pressure required in the system (up to 1350 bar), is created by three pistons in the pump. The high pressure fuel pump delivers fuel at high pressure to the fuel rail, which acts as «hydraulic accumulator» for four nozzles. Since the high pressure fuel pump does not affect the fuel injection timing (unlike conventional diesel fuel injection systems), this means that there is no need to set the high pressure fuel pump when installing the timing belt.

23. The electrical control system includes the BEU and the following sensors:

- A) accelerator pedal position sensor: it informs the ECU about the position of the accelerator pedal and the opening / closing speed «throttle valve»:

- b) coolant temperature sensor: it informs the ECU about the engine temperature:

- V) air flow sensor (it has a built-in air intake temperature sensor); it informs the BEU about the flow rate and temperature of the air passing through the intake tract:

- G) crankshaft position sensor: it informs the ECU about the angular position and engine speed of the crankshaft:

- d) camshaft position sensor: it informs the ECU about the position of the pistons in the cylinders:

- e) fuel temperature sensor (in the presence of): it informs the ECU about the temperature of the fuel in the fuel rail:

- and) fuel pressure sensor (in the presence of); it informs the BEU about the fuel pressure in the fuel rail:

- h) atmospheric pressure sensor (built into BEU); it measures atmospheric pressure to prevent problems when driving at high altitudes.

- And) vehicle speed sensor: it informs the ECU about the vehicle speed:

- To) pressure sensor in the power steering; it informs the ECU when the power steering pump is under load;

- l) air conditioning relay; it informs the BEU about that. when the A/C compressor is under load.

24. All of the above signals from the sensors are analyzed by the BEU, which, based on this information, selects the fuel supply mode. BEU controls fuel injectors (by changing the pulse duration, i.e. the amount of time the injectors remain open to deliver a richer or leaner air/fuel mixture, as required). The composition of the air-fuel mixture is constantly changing at the command of the ECU to provide the best settings for cranking, starting (hot or cold engine) and warming up the engine, as well as for idling the engine, driving the car at a constant speed and accelerating it. The nozzles are activated in pairs, i.e. nozzles #1 and 4 work as one pair and nozzles #2 and 3 as another.

25. In addition, the BEU fully controls the fuel pressure in the fuel rail. This is done by the high pressure fuel regulator and the third piston shut-off solenoid valve, which are located on the high pressure fuel pump. To reduce pressure, the ECU opens the high fuel pressure regulator, which allows excess fuel to return from the pump directly to the tank. The third piston cut-off device is primarily used to reduce engine load, but can also be used to reduce fuel pressure. The shut-off solenoid valve relieves fuel pressure on the third piston of the pump, and as a result, only two pistons pressurize the fuel system.

26. BEU also manages the exhaust gas recirculation system (EGR), described in detail in chapter 4D, and an engine cooling fan.

27. To increase the efficiency of the engine, a turbocharger is installed. It increases engine power by raising the pressure in the intake manifold above atmospheric pressure. Instead of direct air intake to supply the cylinders, air is forced.

28. Energy for the operation of the turbocharger is provided by exhaust gases. Gases pass through a specially shaped housing (turbine housing) while rotating the turbine wheel. The turbine impeller is mounted on a shaft, at the other end of which is mounted another impeller, known as the compressor wheel. The compressor wheel rotates in its own housing, it compresses the incoming air on its way to the intake manifold. The turbocharger shaft is lubricated with pressurized oil supplied through the oil supply line from the main engine oil gallery. Shaft «floats» on «oil cushion». The oil returns to the oil pan through the oil drain line. boost pressure (intake manifold pressure) is limited by the turbine bypass valve, which, under the influence of a pressure-sensitive actuator, diverts exhaust gases from the turbine wheel.

29. If there are any anomalies in any of the signals received from various sensors. BEU introduces «spare» mode. If this happens, the erroneous sensor signal is ignored and the ECU assumes a pre-programmed default value that allows the engine to continue running but with reduced power. If the BEU enters this mode, the control lamp on the instrument panel turns on and the corresponding fault code is recorded in the BEU memory.

30. If the warning light is on, have the vehicle checked by a Peugeot/Citroen dealer or an engine diagnostician as soon as possible. The technician can perform a complete check of the engine management system using a dedicated electronic diagnostic tester that plugs into the diagnostic socket located next to the passenger compartment fuse box.