Attention! Before starting work, please refer to the precautions described in paragraph 2.

Note. Installation will require a complete new set of high pressure fuel lines.

Removing

1. Disconnect the ground wire from the battery (see «Disconnecting the battery»).

2. Remove the four plastic nuts and remove the engine cover (pic. 3.20 a. b).

3. Disconnect the electrical connectors at the fuel injectors and at the piston disconnect device on top of the fuel pump.

4. Turn away two nuts of fastening of a plastic directing plait of electroconducting to a head of cylinders. Remove the guide from the two support pins and slide it towards the fuel rail. If necessary, disconnect the appropriate electrical connectors to allow you to move the wiring harness assembly with the guide to further facilitate access.

5. Release a collar and disconnect a hose of system of ventilation of a crankcase of the engine from a cover of a head of cylinders.

6. Disconnect the fuel supply and return hose quick couplings at the top of the fuel pump: use a small screwdriver to release the locking clip. Seal open connections appropriately to prevent dirt from entering.

7. Disconnect the fuel supply and return fuel hose quick couplings on the fuel filter in the same way and plug open connections. Release the fuel hoses (and on later models, a booster pump) from the corresponding clamps.

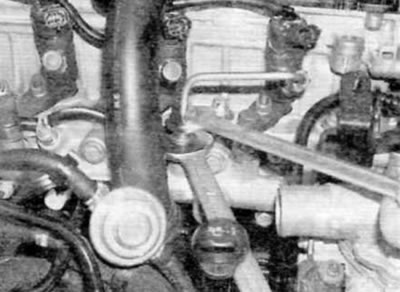

8. Thoroughly clean the high pressure fuel line fittings at the fuel rail, fuel pump and injectors. Using an open end wrench, remove the union nuts securing the high pressure fuel lines to the fuel pump and fuel rail. When unscrewing the union nuts, hold the fittings on the pump and fuel rail with a second wrench. Remove the high pressure fuel line and plug open connections to prevent dirt from entering.

9. Again using two wrenches, hold the fittings and unscrew the union nuts securing the high pressure fuel lines to the fuel injectors and fuel rail. Remove high pressure fuel lines and plug open connections to prevent dirt from entering (pic. 16.9, a, b).

Pic. 16.9, a. Hold the fittings while loosening the union nuts on the high pressure fuel lines connecting the pump and injectors to the fuel rail, then remove the fuel lines and discard them (models with 2.0 l engine)

Pic. 16.9, b. Plug all connections to prevent dirt from entering the fuel system (models with 2.0 l engine)

10. Disunite electric sockets of the gauge of temperature of fuel and the gauge of pressure of fuel on a fuel rail.

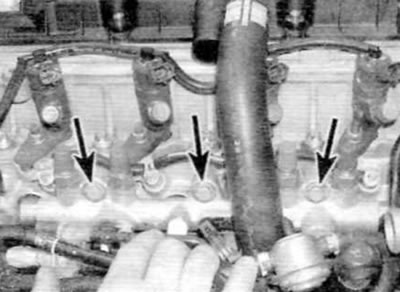

11. Turn out three bolts of fastening of a fuel stage to a head of cylinders and remove directing from a regular place (pic. 16.11, a, b).

Pic. 16.11, a. Remove the bolts (marked with arrows)...

Pic. 16.11, b....and move the fuel rail out of its normal position (models with 2.0 l engine)

Warning. Do not attempt to remove the four male high pressure fuel line fittings from the fuel rail. These items are not supplied separately and disconnecting them during assembly may result in fuel leakage.

12. Purchase a new set of high pressure fuel lines before installation.

Installation

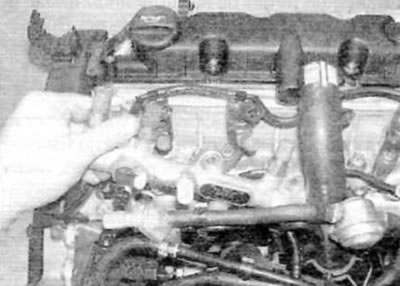

13. Install the fuel rail in place, screw in the three bolts and tighten them to the prescribed torque.

14. Working with one fuel injector at a time, remove the plugs from the fittings on the fuel rail and the corresponding injector. Connect the new high pressure fuel line to the fittings and at this stage screw on the union nuts only by hand.

15. After pre-connecting all four fuel lines, hold the fittings with a wrench and, using a torque wrench and an appropriate adapter, tighten the union nuts to the prescribed torque (pic. 16.15).

Pic. 16.15. Using a torque wrench and a special adapter, tighten the union nuts of the fuel lines (models with 2.0 l engine)

16. Connect the new high pressure fuel line to the fuel pump and fuel rail in the same way and tighten the union nuts to the specified torque.

17. Connect the electrical connectors for the fuel temperature sensor and the fuel pressure sensor.

18. Remove the plugs and connect the quick couplings of the supply and return hoses on the fuel filter and the connections on the top of the fuel pump. Secure the hoses with appropriate clamps.

19. Connect the crankcase ventilation hose to the cylinder head cover.

20. Install the plastic wire harness guide onto the two support studs and secure with nuts.

21. Connect the electrical connectors for the fuel injectors and pump piston shut-off switch and connect all other electrical wiring disconnected for access.

22. Make sure that all connectors are mated and all wiring is secured with the appropriate clamps, and then connect the wire «masses» to the battery.

23. By observing the precautions described in paragraph 2, fill the fuel system as described in paragraph 6. Then start the engine and allow it to idle. Check the high pressure fuel line connections for leaks with the engine idling. If everything is in order, increase the engine speed to 4000 rpm and check for leaks again. Carry out a short road test of the vehicle and check for leaks again upon return. If leaks are found, purchase and install new high pressure fuel lines. Do not attempt to repair even the smallest leak by further tightening the fuel line unions.

24. Finally, install the engine cover.