2. Before making adjustments, warm up the engine to normal operating temperature. Make sure the throttle cable and high idle cable are properly adjusted as described in paragraph 4 and 10.

3. Release the fasteners on the right side and on the top plane of the engine cover, and then carefully, so as not to lose the rubber mounts, remove the cover (pic. 3.1, a-c).

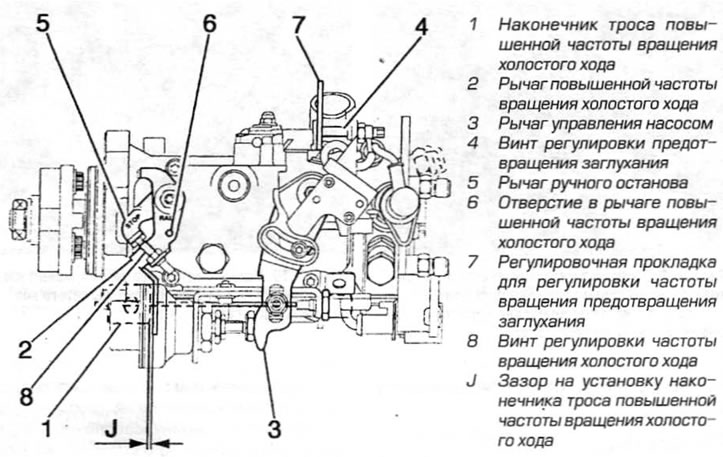

Lucas high pressure fuel pump

4. With the engine idling, position the correct thickness shim (see «Specifications») between the pump control knob and damping prevention adjustment screw (pic. 11.4).

Pic. 11.4. Lucas High Pressure Fuel Pump Adjustment (models with 1.9 l engine)

5. Push the manual stop lever all the way into the stop and hold it in place by inserting a 3.0 mm rod/drill through the hole in the high idle lever.

6. The engine speed must match the value set as the damping prevention speed.

7. If adjustment is necessary, loosen the jam nut, turn the anti-damping adjustment screw as required, and tighten the jam nut.

8. Remove the pin/drill, remove the shim, and verify that the engine is idling at the correct engine speed.

9. If adjustment is necessary, loosen the locknut on the idle speed adjustment screw. Turn the screw as far as required and tighten the lock nut.

10. Move the pump control knob to increase the engine speed to approximately 3000 rpm, then quickly release the lever. The deceleration should last for 2.5-3.5 seconds, and the engine speed should drop approximately 50 rpm below the idle speed.

11. If the deceleration is too fast and the engine stalls, turn the damping prevention adjustment screw a quarter of a turn towards the control knob. If the deceleration is too slow causing insufficient engine braking, turn the screw a quarter of a turn away from the lever.

12. Tighten locknut after adjustment. Check the idle speed and adjust if necessary as described above.

13. With the engine running at idle, check the operation of the manual stop control by turning the stop lever clockwise (pic. 11.4). The engine should stop immediately.

14. Finally, disconnect the tachometer and install the engine cover.

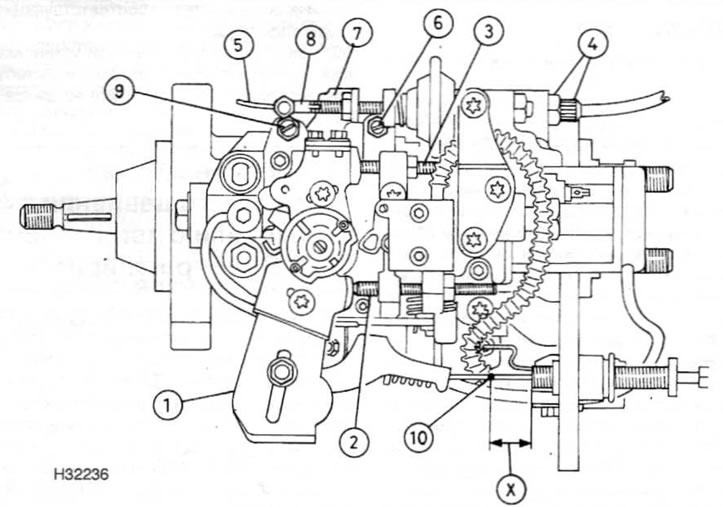

Bosch High Pressure Fuel Pump

15. Loosen the jam nut and back out the damping prevention adjustment screw just enough to release the pump control knob (pic. 11.15).

Pic. 11.15. Bosch high pressure fuel pump adjustment (models with 1.9 l engine)

1. Pump control lever

2. Screw for adjusting the maximum speed

3. Attenuation prevention adjustment screw

4. High idle cable adjustment screw and locknut

5. Cable of increased idle speed

6. Idle speed adjustment screw

7. Lever of increased idle speed

8. Tip of the cable with increased idle speed

9. High idle adjustment screw

10. A mark made on the accelerator cable for adjusting the position switch sensor «throttle valve» X=11.0mm

16. Start the engine and allow it to idle. If the idle speed is incorrect. Loosen the locknut and turn the idle speed adjustment screw as far as required, then tighten the locknut.

17. Insert a shim or feeler gauge of the correct thickness between the pump control knob and the damping prevention adjustment screw.

18. The engine speed must match the value set as the damping prevention speed.

19. If adjustment is needed, loosen locknut, turn damping prevention adjustment screw as required. Tighten locknut.

20. Remove the shim or feeler gauge and allow the engine to idle.

21. Loosen the lock nut and remove the control arm damper adjusting screw located on the back of the control arm and place a 2.0 mm shim or feeler gauge between the damper rod and adjusting screw. Make sure the pump control lever is in the idle position, then turn the adjusting screw until the dipstick (or shim) entered in a light sliding fit between the screw and the damper rod. Hold the screw in this position and tighten the appropriate locknut.

22. Move the high idle lever all the way towards the flywheel end of the engine and verify that the engine speed increases to the desired idle speed. If necessary, loosen the locknut and turn the anti-plug adjustment screw as far as required. Tighten locknut.

23. With the engine running at idle, test the operation of the manual stop control by turning the stop lever. The engine should stop immediately.

24. Finally, disconnect the tachometer.

25. After performing all the adjustments described above, check the adjustment of the position switch sensor «throttle valve», located on the pump control knob as described below.

26. Working with the end of the accelerator cable on the injection pump side, mark the cable 11.0mm from the edge of the cable sheath.

27. Ask an assistant to depress the accelerator pedal so that the mark on the cable is aligned with the edge of the cable sheath. When the cable is in this position, the contacts of the position sensor-switch «throttle valve» should barely open.

28. If adjustment is required, make sure the notch on the cable is still aligned with the edge of the cable sheath, then loosen the two screws securing the switch.

29. Rotate the switch housing as far as it will go. to open the contacts and tighten the screws.

30. Finally, install the engine cover.