Warning. Do not attempt injection advance adjustment procedures without accurate instruments. Appropriate special tools for adjusting the injection advance of the pump can be purchased from major auto parts stores or your Peugeot/Citroen dealer. Please read the safety precautions before starting work paragraph 1 this chapter.

Note. A dial indicator is required to check the injection advance of the high pressure fuel pump (special tool Peugeot/Citroen No. 3089-T) together with a special installation probe (special tool Peugeot/Citroen No. 5003-TD) and adapter (Peugeot/Citroen special tool No. 7010-T). Without this equipment (or the corresponding alternative) The procedure for checking and adjusting the injection advance of the high pressure fuel pump should be carried out by a Peugeot/Citroen dealer or another person who has the appropriate equipment.

1. If the fuel injection advance is checked without removing the pump from the engine, and not during the pump installation procedure, disconnect the wire «masses» from battery (see «Disconnecting the battery») and cover the generator with a clean cloth or plastic bag to protect it from possible fuel spillage.

2. Remove the air intake duct between the air distribution housing and the air filter assembly as described in paragraph 3.

3. Remove the fuel injector lines as described in paragraph 5.

4. Disunite electric sockets on the back party of the fuel pump of a high pressure.

5. Loosen clamping screw and/or nut (whichever is applicable) and slide the end of the high idle cable along the cable so that it is no longer in contact with the high idle lever on the pump (that is, for this lever to return to the limiter) (see paragraph 4).

6. Set the alignment marks of the engine / valve timing assembly (see chapter 2B), to lock the crankshaft. Remove the crankshaft locking tool and then turn the crankshaft back (counterclock-wise) about a quarter of a turn.

7. Turn out the technological plug located on the center between four union connections of pipelines of atomizers on the back side of the high pressure fuel pump. After unscrewing the plug, place a suitable container under the pump to collect the escaping fuel. Wipe up spilled fuel with a clean cloth.

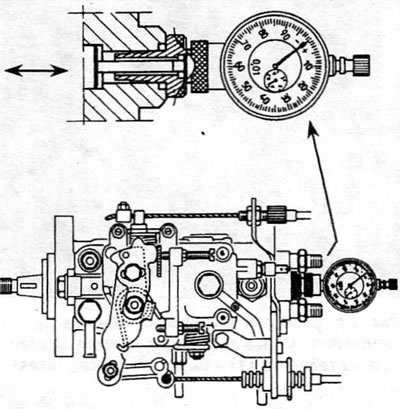

8. Screw the adapter into the back of the pump and connect the dipstick to the dial indicator. Install the indicator and probe into the adapter (pic. 8.8). In the absence of specific Peugeot/Citroen tools, suitable alternative tools can be purchased from many good auto parts stores. Position the indicator so that its plunger is in the middle of the stroke and securely tighten the adapter locknut.

Pic. 8.8. Dial indicator, adapter and setting probe for use on a Bosch pump

9. Slowly rotate the crankshaft in both directions while watching the indicator to determine when the injection pump piston reaches the bottom of its stroke (NMT). When the piston is set correctly, reset the indicator to zero.

10. Rotate the crankshaft slowly in the correct direction of rotation until the crankshaft locking tool can be reinstalled.

11. The reading of the dial indicator must be equal to the fuel pump injection advance value specified in «Specifications» at the beginning of this chapter. If adjustment is necessary, loosen the front and rear nuts and pump mounting bolts and slowly turn the pump casing until you find the point where the dial gauge indicates the prescribed value. Once the pump is in the correct position, securely tighten the front and rear nuts and bolts.

12. Rotate the crankshaft 1% of a turn in the normal direction of rotation. Determine the BDC position for the injection pump piston as described in step 6 and reset the indicator to zero.

13. Slowly rotate the crankshaft in the correct direction of rotation until the crankshaft locking tool can be reinstalled (to return the engine back to TDC). Check injection timing again.

14. If adjustment is required, loosen the pump mounting nuts and bolts and repeat steps. 11-13.

15. Having adjusted the correct injection advance of the pump, unscrew the adapter and remove the dial gauge and dipstick.

16. Screw in the process plug (with sealing washer) into the pump and tighten securely.

17. If this procedure is performed as part of the pump installation sequence, continue as described in paragraph 5.

18. If the procedure is performed without removing the pump from the engine, connect the injector fuel lines by tightening their union nuts to the prescribed torque. Install the intake air line. Connect the battery and then bleed the fuel system (see paragraph 2).

19. Start the engine and adjust the idle speed and stall prevention speed as described in paragraph 9. Also adjust the high idle cable as described in paragraph 4.