General information

1. The exhaust system consists of two sections: a downpipe and a rear pipe. The downpipe is fixed to the manifold with spring-loaded balls (which allows some mobility of the exhaust system). The rear pipe is connected with a clamping ring.

2. The entire length of the system is suspended by rubber mounts.

Removing

3. Each section can be removed individually or, alternatively, the entire system can be removed. Even if only one part of the system needs attention, it is often easier to remove the entire system and separate the sections on a workbench.

4. To remove the system or part of the system, first raise the front or rear of the vehicle and securely support it under it (see «Lifting and placing the car on supports»), Alternatively, park the vehicle over a pit or raise it onto a flyover.

Downpipe

5. Loosen the downpipe clamp ring bolts and unhook the clamp from the flange connection.

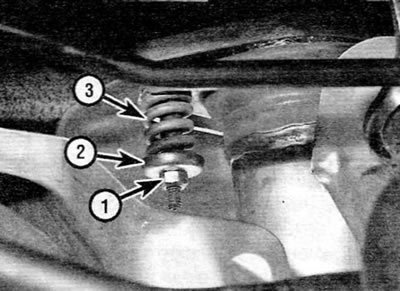

6. Unscrew the two nuts on the flange connection between the downpipe and the manifold and remove the spring caps and springs (pic. 16.6). Remove the bolts and then release the downpipe from the corresponding rubber support (supports) and remove from under the car. Remove the wire mesh gasket from the manifold joint.

Pic. 16.6. Assembly for connecting the intake pipe of the exhaust system to the manifold, consisting of a nut AND), spring cap (2) and springs (3) (when viewed from under the car)

Rear pipe

7. Loosen the rear pipe clamp ring bolts and remove the clamp from the flange connection.

8. Release a back pipe from the corresponding rubber support and remove it from the car.

Complete system

9. Turn away two nuts of fastening of flange connection of a reception pipe to a collector and remove caps of springs and springs. Remove the bolts and then release the system from its respective rubber mounts and remove it from under the vehicle. Remove the wire mesh gasket from the manifold joint.

Heat shield (-s)

10. The heat shields are attached to the underside of the vehicle with various nuts and bolts. Each screen can only be removed after the corresponding section of the exhaust system has been removed. If the screen is removed to gain access to the elements located behind it, in some cases it may be sufficient to unscrew the nuts and / or bolts and simply lower the screen without touching the exhaust system.

Installation

11. Each section is installed in the reverse order of removal, taking into account the following points:

- A) Remove all traces of corrosion from the flanges and replace any necessary gaskets.

- 6) Inspect rubber mounts for signs of damage or deterioration and replace if necessary.

- V) Before assembling the spring-loaded connection, apply high-temperature grease to the mating surfaces of the connection.

- G) If a clamp ring is used in the joint, apply exhaust system assembly paste to the flange joint to ensure a gas-tight joint. Tighten the clamp ring nuts evenly and progressively so that the gap between the clamp sections is equal on both sides.

- d) Before tightening the exhaust system bolts/nuts, make sure that all rubber mounts are correctly positioned and that there is sufficient clearance between the exhaust system and the bottom of the vehicle.

- e) Make sure that the electrical connectors of the oxygen sensors are properly docked, and that the electrical wiring is fixed to the bottom with the appropriate clips.