Cleaning

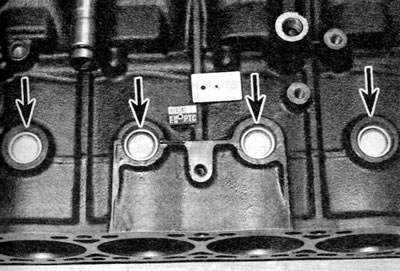

1. Remove from the block of cylinders all external elements and electric switches/sensors. Ideally, for a complete cleaning, remove and smooth (rod) plugs (pic. 12.1). Drill a small hole in the removable plug and screw a self-tapping screw into it.

Pic. 12.1. Cylinder block rod plugs (marked with arrows)

2. Pull the screw with pliers and remove the plug. You can also use an impact puller.

3. If applicable, remove the bolts and piston cooling oil jet tubes from the inside of the cylinder block.

4. Remove all traces of gasket material from the cylinder block/crankcase, being careful not to damage the mating/seal surfaces.

5. Remove all oil channel plugs (in the presence of). The plugs are usually very tightly fitted. It is possible that they will have to be drilled and re-threaded in the holes. When assembling the engine, use new plugs.

6. If any elements are heavily soiled, steam cleaning should be performed.

7. Then clean all oil holes and oil passages again. Rinse all internal channels with warm water. Rinse until clean water comes out. Dry thoroughly and apply a light coat of oil to all mating surfaces to prevent rust. If you have access to compressed air, use it to speed up drying and blow out all oil holes and passages.

Attention! Wear eye protection when working with compressed air.

8. If the block is not very dirty, you can use hot soapy water and a hard brush to clean it. Take your time and work carefully. Regardless of the cleaning method used, clean all lubrication holes and passages very thoroughly and dry all components well. To prevent rust, take protective measures as described above.

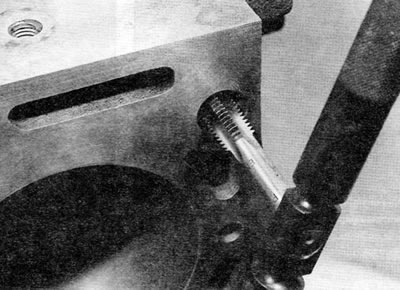

9. Clean all threaded holes; this will ensure the required tightening torques during assembly. To clean the threads, run a tap of the correct size on each of the holes. This will remove rust, corrosion products, thread sealant or sludge and repair damaged threads (pic. 12.9). If possible, use compressed air to clear holes from previous cleaning.

Pic. 12.9. Use a suitable tap to clean the threaded holes in the cylinder block

Attention! Wear eye protection when working with compressed air.

10. Apply appropriate sealant to the new oil port plugs and insert the plugs into the holes in the block. Tighten them securely. Also apply a suitable sealant to the new smooth plugs and use a piece of machined pipe or a socket to insert the plug into the cylinder block.

11. On engines with oil piston cooling nozzles, clean the threads of the piston cooling oil nozzle mounting bolts and apply a drop of locking compound to the threads of these bolts. Install the oil pipes on the cylinder block, screw in the bolts and tighten them to the prescribed torque.

12. If the engine cannot be reassembled immediately, cover it with a large plastic bag or just cling film to keep it clean. Protect all mating surfaces and cylinders as described above to prevent rust.

Inspection

13. Visually check the cylinder block for cracks, rust and corrosion. Inspect threaded holes for stripped threads. If there has been a case of an internal coolant leak, it may be helpful to take the cylinder block to an engine overhauler to have it checked with special equipment. At detection of defects eliminate them if it is possible, or replace the block of cylinders.

14. Check each cylinder for scratches and burrs. Check for a wear ridge in the top area of the cylinder. This ridge indicates increased cylinder wear.

15. Accurate measurement of cylinder diameter requires special equipment and experience. It is recommended to have the measurement performed by an engine rebuilder who is also able to provide the appropriate pistons (if it is possible), if the cylinder bore is required during engine repair.

16. If «mirrors» The cylinders and pistons are in acceptably good condition and show no increased wear and the clearances between the pistons and the cylinder walls are correct, only the piston rings need to be replaced. If this is the case, the cylinders should be honed to allow the new rings to properly «sit down» and provide the best (as much as possible) seal. An engine rebuilder will do the job for a reasonable price.

17. At the time of this writing, it was not known if repair-note size pistons are available for all models. See your Peugeot/Citroen dealer or engine rebuilder for the latest piston availability. If oversized pistons are available (purchased either from a Peugeot/Citroen dealer or from another source), you can bore the cylinders and install oversized pistons. If oversize pistons are not available and the cylinders are worn out, block replacement seems to be the only option.