2. Gently pry the rings out of the grooves. Use two or three old feeler gauges to prevent the rings from springing back into the vacated grooves (pic. 13.2). Be careful not to scratch the piston with the ends of the ring lock. The rings are brittle and if unclenched too much, they will break. In addition, they are very sharp - protect your palms and fingers. Keep in mind that the third (oil scraper) ring built-in spacer (expander). Always remove rings through the top of the piston. If you install «old» rings, store each set of rings with the corresponding piston.

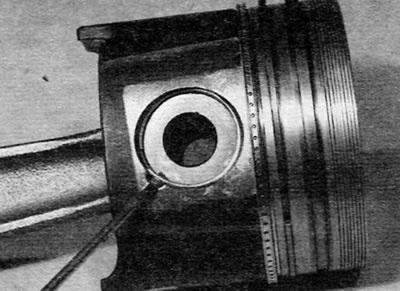

Pic. 13.2. Removing the piston ring with a flat feeler gauge

3. Remove carbon deposits from the top of the piston with a scraper. After removing most of the deposits, you can use a wire brush (or fine sandpaper).

4. Remove carbon deposits from the piston grooves. To do this, use «old» ring. Break the ring in half (be careful not to cut your fingers - piston rings are very sharp).

Warning. Be careful to remove only carbon deposits - do not remove metal or scratch the sides of the grooves.

5. After removing carbon deposits, clean the piston and connecting rod assembly with kerosene or a suitable solvent and dry thoroughly. Clean the oil return holes (in grooves).

6. If pistons and «mirrors» cylinders are not damaged and do not have increased wear, and the cylinder block does not require cylinder boring, original pistons can be installed in place. Normal piston wear shows up as uniform vertical wear on the side pressure surfaces of the pistons and slight slack in the top ring in the corresponding groove. Be sure to use new piston rings when assembling the engine.

7. Carefully inspect each piston for cracks in the skirt, near the piston pin bore, and in the areas between the piston ring grooves.

8. Inspect the piston for holes in the piston head, «burnt» area on the edge of the head and scratches and wear on the skirt. If the skirt is scratched or frayed, the engine may have been overheated and/or abnormal combustion has occurred resulting in an excessively high operating temperature. The cooling and lubrication systems should be carefully checked. Traces of burning on the walls of the pistons indicate a breakthrough of gases. hole in the piston head or «burnt» areas on the edge of the piston head indicate abnormal combustion (pre-ignition or detonation). If any of these defects are present, their causes should be found out and eliminated. Otherwise, the damage will happen again. Causes may be incorrect injection timing or injector failure (whichever is applicable).

9. Pitting of the piston indicates coolant seepage into the combustion chamber and/or crankcase. The cause must be eliminated. If this is not done, the problem may also appear on a rebuilt engine.

10. Carefully inspect each connecting rod for signs of damage such as cracks near the upper end and lower end bearings. Check if the connecting rod is bent. Unless the engine has been seized or severely overheated, damage is very unlikely. A detailed inspection of the connecting rod assembly should only be performed by a dealer or engine rebuilder with the necessary equipment.

11. Connecting rod bearing cap nuts should be replaced after each unscrewing. Although Peugeot/Citroen does not recommend that the bolts be replaced as well, it is recommended that nuts and bolts be replaced as a set.

12. Piston pins - floating type. Fixation is provided by locking rings. The pistons can be separated from the connecting rods as described below.

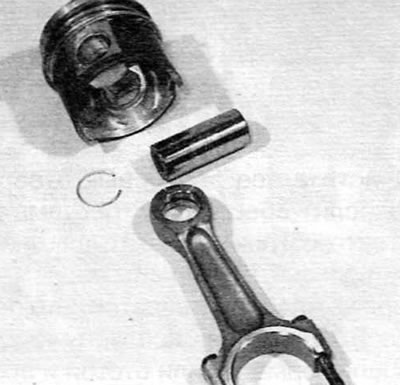

13. Using a small flathead screwdriver, remove the circlips from the piston and push out the piston pin (pic. 13.13, a-c). To extract the finger, the force of the hand should be enough. Mark the piston and connecting rod to ensure correct assembly. Discard retaining rings; when assembling, use new ones.

Pic. 13.13, a. Remove retaining ring...

Pic. 13.13, b....remove the piston pin

Pic. 13.13, c....and separate the piston from the connecting rod

14. Inspect the piston pin and connecting rod bearing for signs of wear or damage. If worn, both the piston pin and bushing will need to be replaced. The situation can be corrected by replacing both the pin and the bushing. However, changing the bushing is a job for a specialist: a press is required, and the new bushing must be turned to the required size.

15. The connecting rods themselves should not require replacement unless the engine has seized or some other major mechanical failure has occurred. Visually inspect the geometry of the connecting rods and if they are deformed, show them to an engine overhauler. It can perform a more detailed check.

16. Inspect all items. Obtain the required new parts from your dealer or engine rebuilder. When purchasing new pistons, be aware that they will come complete with piston pins and circlips. Retaining rings can also be purchased separately.

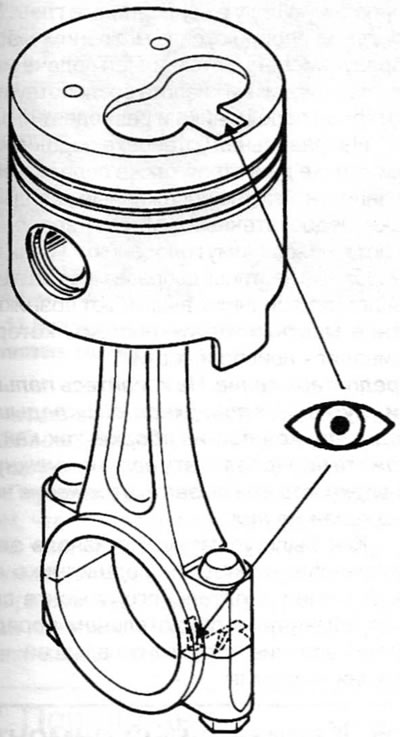

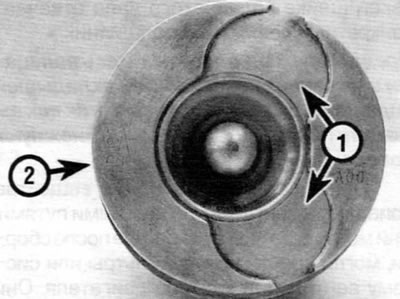

17. Assemble the piston and connecting rod so that the notch or arrow on the piston head or the valve notch on the bottom of the piston is located, as shown, relative to the notches in the bearing shells of the lower head of the connecting rod (pic. 13.17, a, b). Apply some clean engine oil to the piston pin. Insert a finger into the piston and pass through the upper head of the connecting rod. Check if the piston turns freely on the connecting rod. Secure the piston pin with two new circlips. Ensure that each retaining ring is correctly seated in its corresponding groove on the piston.

Pic. 13.17, a. On 1.8L and 1.9L engines, ensure that the undercut on the piston crown is aligned with the cutout in the connecting rod bearing shell as shown

Pic. 13.17, b. On 2.0L engines, valve recess (1) on the piston crown must be located on the side opposite the cutout in the connecting rod bearing shell (2, not visible)