Axial clearance check

1. If you want to check the crankshaft end play, this should be done while the crankshaft is still in the cylinder block/crankcase, but it can be moved (see paragraph 10).

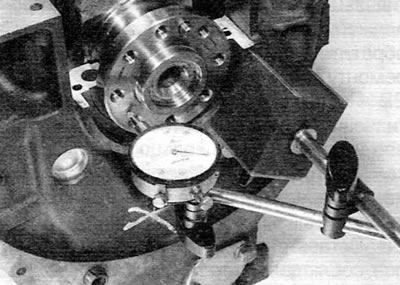

2. Check up an axial backlash, using the arrow indicator which plunger is brought to an end face of a cranked shaft. Fully move the crankshaft to one side and set the indicator to zero. Move the crankshaft all the way to the other side and read the axial clearance. The result can be compared with the prescribed value. You can then decide if new thrust washers are required (semirings) (pic. 13.2).

Pic. 13.2. The axial clearance of the crankshaft can be checked using a dial gauge...

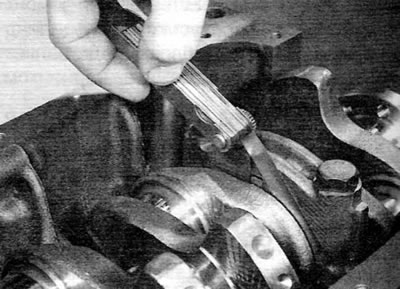

3. If a dial indicator is not available, a feeler gauge can be used. First, press the crankshaft all the way towards the flywheel, and then use a feeler gauge to measure the gap between the web of the connecting rod journal No. 2 and the thrust washer (pic. 13.3).

Pic. 13.3....or with «fan» probe

Inspection

4. Clean the crankshaft with kerosene or a suitable solvent and dry it. It is advisable to use compressed air, if you have such an opportunity. Check and, if necessary, clean the oil holes using a pipe punch or similar «probe». The holes must not be blocked.

Attention! Wear eye protection when working with compressed air.

5. Check the main journals and connecting rod journals for uneven wear, nicks, pitting, and cracks.

6. The wear of the bearings of the lower heads of the connecting rods is accompanied by a clear metallic knock during engine operation (especially noticeable when the engine is accelerating from low speed) and some loss of oil pressure.

7. Wear of the main bearings is accompanied by severe engine vibration and rumbling (the level of which increases with an increase in the frequency of rotation of the crankshaft), and loss of oil pressure.

8. Check the roughness of the journal by running your finger lightly over the running surface of the bearing. Any increased roughness (which will be accompanied by obvious bearing wear) indicates that the crankshaft requires regrinding (if allowed) or replacement.

9. Check at each end of the crankshaft the seal contact surfaces for wear and damage. If the seal has left a deep groove on the surface of the crankshaft, consult an engine overhaul specialist; repairs may be possible. If not, a new crankshaft will be required.

10. Take the crankshaft to an engine rebuilder to assess journal wear. If the presence of increased wear is obvious, he will be able to give you the necessary recommendations for regrinding the crankshaft and acquiring new bearing shells.

11. If the crankshaft has been ground, check for burrs around the crankshaft oil holes (holes are usually chamfered, so there should be no burrs unless regrinding has been carelessly done). Remove burrs with a fine file or scraper and clean the oil holes thoroughly as described above.

12. At the time of this writing, it is not known if Peugeot/Citroen manufactures oversized bearing shells for all of the engines described. On some engines, if the crankshaft journals have not yet been reground, it may be possible to regrind the crankshaft and install oversized liners. If no oversized bearings are provided and the crankshaft wear is out of tolerance, the crankshaft must be replaced. Contact your dealer or engine rebuilder for parts availability.