Note. Before starting work, read the precautions described in paragraph «Safety first!» and in paragraph 1 this chapter.

1. If the starter does not work when the ignition key is turned to the appropriate position, the following factors may be the cause of this:

- A) Faulty engine immobilizer.

- b) Battery defective.

- V) The electrical connections between the ignition switch, traction solenoid, battery and starter are not capable of delivering the required current from the battery through the starter to «mass».

- G) Faulty traction solenoid,

- d) Mechanical or electrical starter failure.

2. To check the battery, turn on the headlights. If they dim after a few seconds, this indicates that the battery is low - recharge it (see paragraph 3) or replace. If the headlights are bright, turn the ignition switch to the start position and watch the headlights. If they dim, this indicates that the current reaches the starter, and therefore the fault must lie in the starter. If the headlights keep burning bright (and there is no click of the starter solenoid), then the fault lies in the electrical circuit or in the electromagnet (see the following points). If the starter turns slowly when turned on and the battery is in good condition, this indicates either a faulty starter or significant resistance somewhere in the electrical circuit.

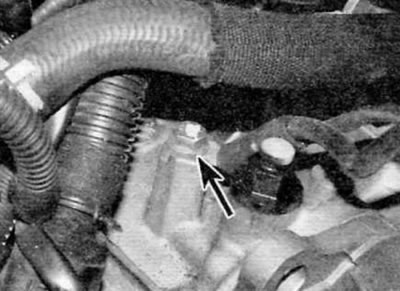

3. If a fault in the electrical circuit is suspected, disconnect the battery wires (including the ground wire going to the body), starter/solenoid wiring and tire (-s) engine/gearbox mass, which is located on the gearbox housing (pic. 10.3). Thoroughly clean the contacts and reconnect the wires and wiring. Using a voltmeter or test light, verify that full battery voltage is being applied to the positive starter terminal. Check the quality of the ground. Apply petroleum jelly to the battery terminals to prevent corrosion. Corrosion in connections is one of the most common causes of electrical system failures.

Pic. 10.3. Engine/Gearbox Ground Bar (marked with an arrow)

4. If the battery and all connections are in good condition, check the electrical circuit by disconnecting the wire from the traction solenoid terminal. Connect a voltmeter or test lamp between the end of the wire and a good point «masses» (such as negative battery terminal), and check if the wire is live when the ignition switch is turned to the start position. If everything is in order, the electrical circuit is normal. If not, the wiring can be checked as described in chapter 12.

5. The traction solenoid contacts can be checked by connecting a voltmeter or test lamp between the terminal that connects the positive wire from the battery to the starter solenoid and «weight». When the ignition switch is turned to the start position, the voltmeter should show voltage or the test lamp should come on (depending on what is being used). If there is no indication or the lamp does not light, the solenoid is defective and must be replaced.

6. If it is proved that the electrical circuit and electromagnet are normal, the fault must lie in the starter itself. You can give the starter for repair to a specialist. But first, estimate the cost of spare parts, as it may be cheaper to purchase a new or remanufactured starter on an exchange basis.