Note: Refer to the asbestos dust warnings given at the beginning of paragraph 4.

Removing

1. If you are not going to remove from the vehicle and separate for overhaul the engine assembly with gearbox (see relevant part chapter 2), the clutch release mechanism can be reached after removing the gearbox only, as described in chapter 7.

2. Different disengagement mechanisms can be used depending on the type of gearbox. For information on identifying the type of gearbox, refer to chapter 7, and then continue as described below under the appropriate subheading.

MA5 and VEZ/5 gearboxes

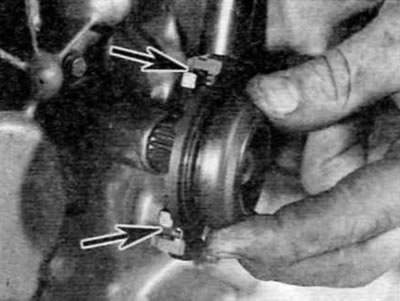

3. Unhook the clutch release bearing from the fork and remove it from the input shaft guide sleeve (pic. 5.3).

Pic. 5.3. Unhook the clutch release bearing from the fork and remove it from the input shaft (MA5 and VEZ/5 gearboxes)

4. Now remove the clutch release lever from the top of the release fork shaft. This is done in one of two ways, depending on the type of gearbox and year of manufacture. Determine how the release lever is attached to the release fork shaft and, depending on the type, proceed as follows:

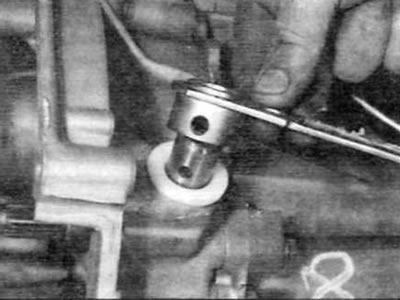

- A) If the release lever is secured to the shaft with a roll pin, drive out the roll pin using a suitable center punch and remove the release lever from the top of the release fork shaft (pic. 5.4, a, b). Purchase a new pin for installation.

- b) If the release lever is secured to the shaft with a stud with a protruding threaded end, screw a nut onto the threaded end of the stud. Tighten the nut to pull the pin out of the lever, and then remove the release lever from the top of the release fork shaft. Purchase a new pin for installation.

Pic. 5.4, a. Knock out the roll pin with a suitable center punch...

Pic. 5.4b....and remove the release lever from the top of the release fork shaft (MA5 and VEZ/5 gearboxes)

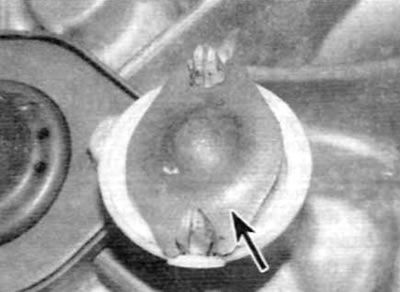

5. Press the locking tabs, and then release the upper bushing from the housing and remove it from the release fork shaft. Unhook the shaft from the lower bushing and remove it from the gearbox (pic. 5.5, a, b). The lower bushing can then be removed from the gearbox housing.

Pic. 5.5, a. Release the upper sleeve from the gearbox housing and remove it from the shaft...

Pic. 5.5b....then release the shaft from the lower bushing (marked with an arrow) and take it out of position (MA5 and VEZ/5 gearboxes)

Gearbox BE4/5

6. Squeeze the tabs on the clip and remove the release fork from the ball stud. Remove the shim, if applicable. Unscrew the support pin from the gearbox housing (pic. 5.6, a-c).

Pic. 5.6, a. Squeeze the clamp and remove the switch off...

Pic. 5.6b....remove the shim (marked with an arrow)...

Pic. 5.6, c....and then unscrew the ball stud (gearbox BE4/5)

7. Slide the clutch release bearing off the input shaft guide and unhook the release fork levers (pic. 5.7).

Pic. 5.7. Unhook the clutch release bearing from the release fork (gearbox BE4/5)

Inspection

8. Check the release mechanism and replace any item that is worn or damaged. Carefully check all bearing surfaces and contact points.

9. When checking the clutch release bearing directly, keep in mind that it is recommended to replace it without fail. Check that the contact side of the clutch release bearing rotates smoothly and easily, without noise or binding. Also check that the surface itself is smooth and unworn, free of cracks, pitting or burrs. If there is any doubt about the condition, the bearing should be replaced.

Installation

MA5 and VEZ/5 gearboxes

10. Apply a small amount of molybdenum disulphide grease to the shaft bushings and contact surfaces of the release fork.

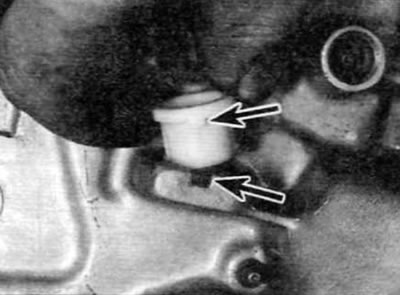

11. Position the lower bushing in the gearbox, making sure that it is securely fixed with the locating tabs, and install the release fork shaft (pic. 5.11). Slide the top bushing down the shaft and secure it in the gearbox housing.

Pic. 5.11. Make sure that the protrusion of the lower bushing is correctly located in the gearbox housing (MA5 and VEZ/5 gearboxes)

12. Install the release lever on the shaft. Align the hole in the lever with the hole in the shaft and secure the shaft by inserting a new roll pin or retainer into the hole. Slide the clutch release bearing onto the input shaft guide sleeve and engage it with the release fork.

13. Install the gearbox as described in chapter 7.

Gearbox BE4/5

14. Apply some molybdenum disulphide grease to the ball stud.

15. Insert the outer end of the release fork through the rubber boot on the side of the front section of the transmission case.

16. Insert the release fork levers into engagement with the clutch release bearing lug, and then slide the clutch release bearing onto the input shaft guide bushing.

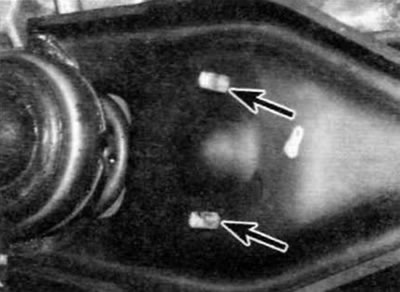

17. Place a shim on the ball stud clamp tabs, and then slide the yoke onto the stud, making sure that the clip tabs engage the yoke correctly (pic. 5.17).

Pic. 5.17. Correctly insert locking tabs (marked with arrows) engaged with the release fork (gearbox BE4/5)

18. Install the gearbox as described in chapter 7.