Removing

1. Apply the parking brake fully, raise the front of the vehicle and securely jack it up (see «Lifting and placing the car on supports»).

2. Drain the gear oil as described in paragraph 2. Then install the drain plug and filler/level plug and tighten to the specified torque.

3. Remove the air filter and intake air line (-s), as described in the relevant part chapter 4. On D9B diesel engines, also remove the air distribution housing as described in chapter 4A.

4. Remove the battery, battery shelf, and base plate as described in chapter 5A.

5. Remove both axle shafts as described in chapter 8.

6. Remove the starter as described in chapter 5A.

7. Unhook the clutch cable end from the fork/disengage lever (see chapter 6). Press the tabs and release the cable sheath from the bracket on the gearbox.

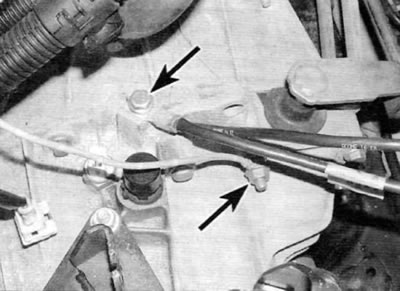

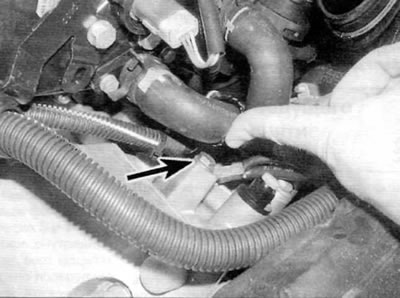

8. Disunite an electric socket of the switch of lanterns of a backing, the TDC sensor and a speedometer drive. Loosen the nuts/bolts and disconnect the ground rails from the gearbox housing (pic. 7.8, a, b). If necessary, disconnect the electrical connectors of the various additional switches/sensors, release the wiring harness from its clips, and position it away from the transmission.

Pic. 7.8, a. Loosen the nut, remove the bolt (marked with arrows) and disconnect the wires «masses» from gearbox (MA5 gearbox)

Pic. 7.8b. Remove the bolt (marked with an arrow) and disconnect the wire «masses» from gearbox (gearboxes VEZ/5 and BE4/5)

9. On the MA5 gearbox, unscrew the bolt securing the exhaust pipe to the corresponding support bracket on the gearbox.

10. On MA5 gearboxes up to 1998, unscrew the nut (with puck), and then remove the shaft that secures the gear selector rod to the shift lever on the gearbox. Unhook the link from the gear lever on the gearbox. On all other transmissions, use a flathead screwdriver to carefully separate the shift linkage ball joints from the corresponding levers on the transmission. Position the linkages away from the gearbox.

11. On power steering models, remove the nuts and bolts and release the power steering piping support brackets from the transmission. Position the piping away from the box so as not to damage it during removal.

12. Turn out a bolt (-s) and remove the lower flywheel cover (if applicable) from the gearbox.

13. On gearboxes BE3 / 5 and BE4 / 5, remove the speedometer drive housing from the gearbox, as described in paragraph 6.

14. Place a jack with a wooden block on its head under the engine to unload its supports. Alternatively, attach a pair of lifting eyes to the engine and relieve the engine mounts with a hoist or engine support bar.

15. Place a jack with a block of wood on the head under the gearbox and raise the jack just enough to support the weight of the gearbox.

16. Turn away a nut and turn out a bolt of fastening of a coupler of a back support of the engine/transmission to an arm on a stretcher.

17. Loosen the central nut (with puck) on the left engine/gearbox mount. Remove the two bolts / unscrew the nuts securing the support to the support bracket and remove the rubber support.

18. On the MA5 gearbox, unscrew the three nuts and remove the support plate from the top of the gearbox.

19. On gearboxes BE3 / 5 and BE4 / 5, remove the washer and spacer from the support pin, and then unscrew the pin from the top of the gearbox housing. Remove the large spacer plate from the support stud.0 With the jack supporting the weight of the transmission, remove the remaining transmission case-to-engine bolts. Note the mounting position of each bolt and associated brackets when removed so that this information can be used during installation. Last check that all elements are disconnected and located away from the gearbox so as not to interfere with removal.

21. After unscrewing the bolts, move the jack with the gearbox to the left to remove it from the dowel pins, and then lift the end of the gearbox with the differential up to unhook it from the subframe.

Warning. Be extremely careful not to allow excessive deformation of the exhaust system components or damage to the radiator when moving the engine. On models equipped with air conditioning, care must also be taken to ensure that the accessory drive belt pulleys do not damage the refrigerant lines on the right side of the engine compartment.

22. After releasing a transmission lower a jack and take a transmission from under the car. Remove the dowel pins from the gearbox or engine if they are not secured and store them in a safe place.

Installation

23. The gearbox is installed in the reverse order of removal, taking into account the following points:

- A) Apply some high temperature grease (Peugeot/Citroen recommends using Molykote BR9 plus, available from your dealer) on the splines of the input shaft of the gearbox. Do not apply too much grease, as there is a possibility of grease getting on the clutch disc.

- b) Install the dowel pins properly before installation.

- V) On gearboxes BE3 / 5 and BE4 / 5, before installing the stud of the left support of the power unit on the gearbox, apply a compound to the thread of the stud to lock the threaded connections. Tighten the stud to the prescribed torque.

- G) Tighten all nuts and bolts to the specified torque (if specified).

- d) Replace cuffs semiaxes (paragraph 5), and then install the axle shafts (see chapter 8).

- e) Finally, fill the gearbox with the prescribed oil in the specified quantity as described in paragraph 2.