External hinge

1. Remove the axle shaft as described in paragraph 2.

2. Loosen the outer band of the rubber boot by cutting it with a hacksaw (pic. 4.2). Open the clamp and remove it from the cover.

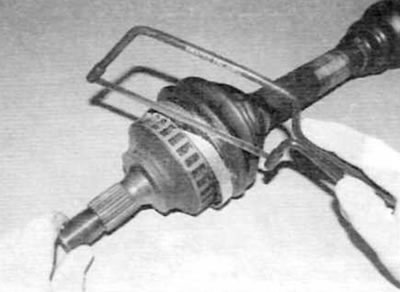

Pic. 4.2. Release the outer clamp of the rubber boot by cutting it with a hacksaw

3. Using a screwdriver, loosen the inner clamp of the rubber boot, and then, using quick-drying paint, mark the position of the end of the boot on the axle shaft (pic. 4.3, a. b).

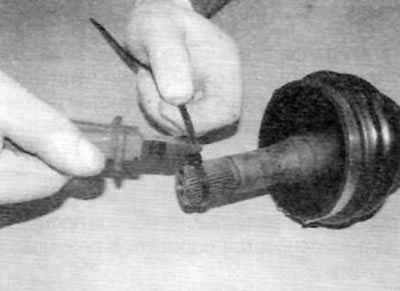

Pic. 4.3, a. Use a screwdriver to loosen the inner clamp...

Pic. 4.3b....then mark the position of the end of the boot on the axle shaft

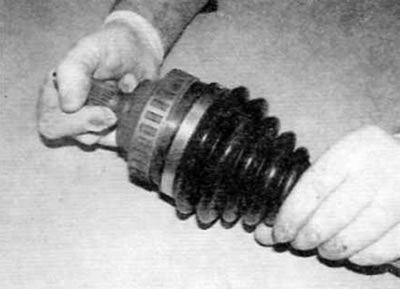

4. Slide the rubber boot off the axle shaft to expose the outer CV joint and remove excess grease (pic. 4.4). When performing this operation, it is recommended to work with rubber gloves.

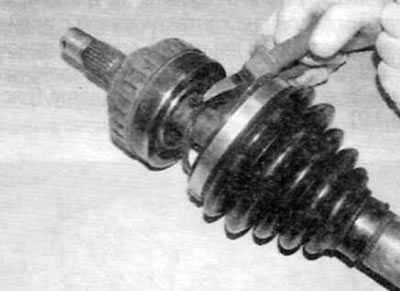

Pic. 4.4. Remove the cover from the axle shaft and remove excess grease

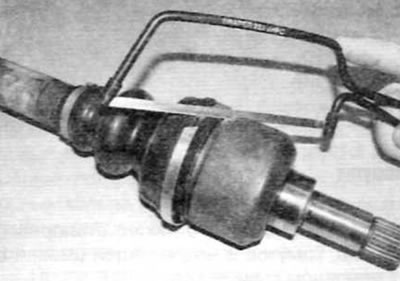

5. Hold the axle shaft and use a hammer to hit the end of the outer joint with a hammer to knock it out of the end of the axle shaft (pic. 4.5). The pivot is supported on the axle shaft by a circlip, and releasing the pivot in this way releases the circlip, allowing the pivot to be removed.

Pic. 4.5. Strike the edge of the outer joint sharply to remove it from the end of the axle shaft

6. After removing the joint assembly, remove the circlip from the groove on the splined end of the axle shaft and discard it (pic. 4.6). When assembling, install a new retaining ring.

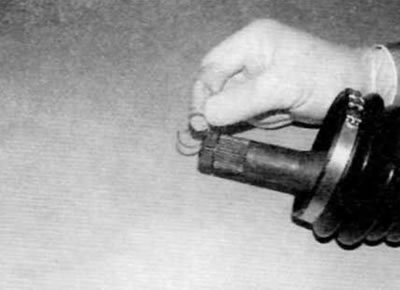

Pic. 4.6. Remove the retaining ring from the groove on the splined end of the axle shaft

7. Remove a rubber boot from a half shaft and shift an internal collar.

8. After removing the constant velocity joint from the axle shaft, erase as much as possible «old» lubricants (do not use solvent) with a hinge so that you can inspect its elements.

9. Slide the inner spline driver side to side to open each ball in turn at the top of the respective track. Inspect the balls for cracks, dents, or signs of surface pitting.

10. Inspect the ball tracks on the inner and outer members. If the tracks are broken, the balls will not «sit» tightly. At the same time, check the separator for cell wear or cracks between cells.

11. If any elements of the constant velocity joint are worn or damaged, it will be necessary to replace the entire joint assembly or even the entire axle shaft (if no hinge elements are supplied separately). See your Peugeot/Citroen dealer for more information on spare parts. If the hinge is in satisfactory condition, purchase a repair kit. consisting of a new boot, retaining ring, clamps and the proper lubricant in the correct amount.

12. To install a new boot, follow the steps shown in the pictures (pic. 4.12, a-o). Follow the prescribed sequence and strictly follow the captions under the figures. Keep in mind that different types of clamps may be used, but the installation procedure will be the same as shown.

Pic. 4.12, a. Put on a new inner collar of the cover on the axle shaft...

Pic. 4.12b....then a new cover with an external collar

Pic. 4.12, c. Install a new circlip into the groove on the axle shaft...

Pic. 4.12, d....then compress the retaining ring with a clamp

Pic. 4.12 e. Using side cutters, tighten the clamp as far as possible, and then cut off the ends

Pic. 4.12, e. Slide the hinge onto the splined end and bring the inner element to the collar

Pic. 4.12, f. Strike the end of the pivot sharply to dislodge the collar and guide the inner member over the retaining ring

Pic. 4.12, s. After installing the hinge, cut off the clamp

Pic. 4.12, and. Pack the hinge with the recommended lubricant; take half of the prescribed amount of lubricant...

Pic. 4.12, k.... inject grease into the ball tracks, while turning the hinge

Pic. 4.12, l. Stuff the cover with the rest of the grease...

Pic. 4.12, m.... then slide the cover over the outer hinge element and fix it in the corresponding groove

Pic. 4.12, n. Insert the inner end of the cover into the groove on the axle shaft, guided by the mark made during removal, install the clamp and compress its protruding part with side cutters

Pic. 4.12, o. Fix the outer clamp of the cover in the same way

13. Make sure that the constant velocity joint moves freely in all directions, and then install the axle shaft on the vehicle, as described in paragraph 2.

Internal hinge

14. Remove the axle shaft as described in paragraph 2.

15. Measure the distance between the inner edges of the inner and outer rubber boots of the axle shafts and note the resulting value for use during installation (pic. 4.15).

Pic. 4.15. Measure and record the distance between the inner edges of the inner and outer axle boot

16. Loosen the inner and outer clamps of the rubber boot by cutting them with a hacksaw (pic. 4.16). Release the clamps and remove them from the cover.

Pic. 4.16. Release the clamps of the cover by cutting them with a hacksaw

17. Remove the outer element of the hinge from the tripod and remove the spring and thrust cap from the outer element (pic. 4.17, a, b). After removing the outer element, check if the rollers are secured to the tripod with caulking or retaining rings. If the casters are not attached to the tripod, wrap the tripod with duct tape to hold them in place.

Pic. 4.17, a. Remove the outer hinge element from the tripoid...

Pic. 4.17b....and remove the spring and thrust cap from the outer element

18. Remove as much excess grease as possible from the tripod and rollers (pic. 4.18). When performing this procedure, it is recommended to work with rubber gloves.

Pic. 4.18. Remove as much grease from the tripod and rollers as possible

19. You can now remove the tripod with a hydraulic bearing puller with two or three jaws or a press. When using a puller, lock its grips behind the tripod so that they do not come into contact with the hinge rollers. When using a press, support the underside of the tripod and press the axle shaft out of the hinge (pic. 4.19).

Pic. 4.19. Remove the tripod using a hydraulic bearing puller with two or three quarters or a press

20. After removing the tripoid, slide the cover off the end of the axle shaft.

2.1 Remove as much as possible «old» lubricants (do not use solvent) with a hinge so that you can inspect its elements. Examine the tripoid. rollers and outer member for signs of damage or wear. Check the smoothness of the movement of the rollers on the fingers of the tripod. If there is wear or damage, replace the entire joint assembly (if possible) or even the entire axle (if no hinge elements are supplied separately). See your Peugeot/Citroen dealer for more information on spare parts. If the hinge is in satisfactory condition, purchase a repair kit consisting of a new boot, clamps, and the correct amount of lubricant.

22.. To install a new cover, follow the steps shown in the pictures (pic. 4.22, a-l). Follow the prescribed sequence and strictly follow the captions under the figures. Keep in mind that different types of clamps may be used, but the installation procedure will be the same as shown.

Pic. 4.22 a. Put on a new inner collar and a cover on the axle shaft

Pic. 4.22b. Clamp the axle shaft in a vise, put the tripoid on the splines and reinsert it into its normal position

Pic. 4.22, c. Using a small punch, mint the tripoid on the axle shaft in three places

Pic. 4.22, d. Stuff the tripoid and case with lubricant; take half of the prescribed amount of lubricant...

Pic. 4.22, e.... inject grease into the bearing rollers

Pic. 4.22, e. Install the spring and thrust cap in the outer element...

Pic. 4.22, f....then pack the rest of the lubricant into the outer element

Pic. 4.22, s. Place the outer element on the tripod and fix the cover in the groove of the outer element

Pic. 4.22, and. Push the outer piece completely onto the tripod and lift up the inner edge of the case to release air from underneath

Pic. 4.22, j. Install the outer clamp on the cover and squeeze its protruding part with the help of side cutters

Pic. 4.22, l. Position the inner end of the cover according to the size recorded during removal, slide the clamp on and crimp the protruding part

23. Make sure that the constant velocity joint moves freely in all directions, and then install the axle shaft on the vehicle, as described in paragraph 2.